Our Business

Contributing to the society with the state-of-the-art technology

Our company adopts the "lost wax process" as a method of casting precision molded articles.

This casting process is characterized by the ability to manufacture, with high dimensional accuracy, materials which are particularly difficult to machine and products having complicated shapes.

With global warming issues coming under closer scrutiny, this lost wax process is essential for manufacturing turbine blades having excellent heat resistance that are required to improve the thermal efficiency in gas turbine combined cycle power generation that is attracting lots of attention all over the world as a measure to deal effectively with the global warming issues.

Especially, a technology for creating cavities (air holes) through which air and steam are allowed to flow into blades to cool turbine blades so that they can withstand a gas turbine inlet temperature of 1,650℃ is our company's advanced technology.

We believe firmly that gas turbine blades and precision molded articles such as high temperature components for gas turbines manufactured at our company play an active role, through our customers, in combined cycle power generation plants with a thermal efficiency of more than 50% worldwide, thereby contributing toward preventing global warming.

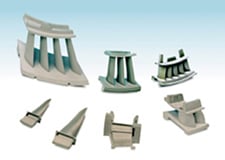

Products related to gas turbines