Boiler Services

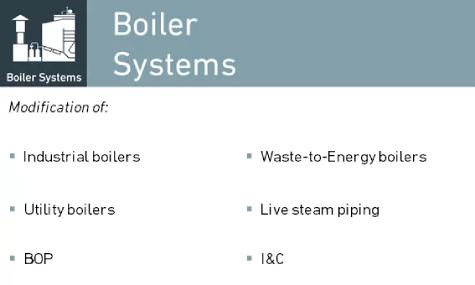

Mitsubishi Power Europe provides a complete array of services for modernization of power plants, which differ in design and size for all conventional fuels. We deliver customer-oriented service and rehabilitation for utility steam generators (boilers) and components, e.g. mills, burners, firing systems, coal feeders etc.

- All-round Service for your Plant

- Tried-and-tested Modernization and Rehabilitation

- 24/7 Emergency Call

+49 (0) 172 26 08 481

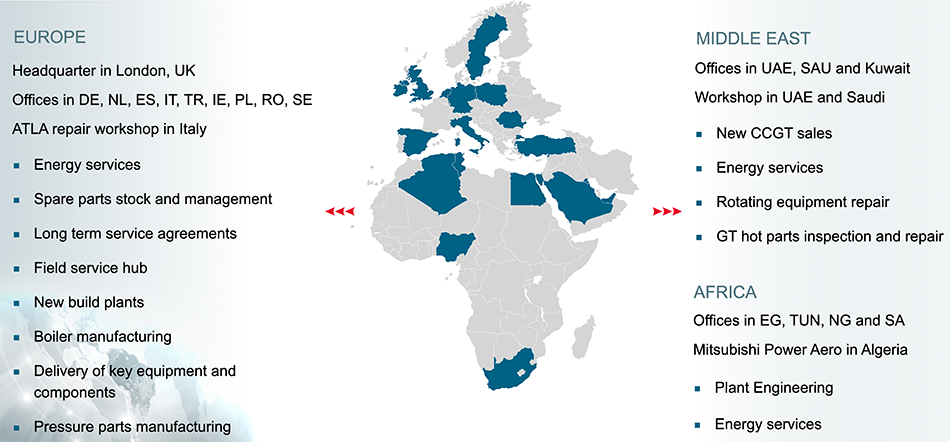

Furthermore, Mitsubishi Power Europe has its own manufacturing facilities which include pressure parts, burners and coal mills to provide timely, high quality service. As designer and manufacturer of original parts, Mitsubishi Power Europe is the ideal partner for revamping and spare parts requirements. Our integrated service business has bases and branches in Europe, Middle East and Asia, which enables us to react swiftly and flexibly to customer needs.

Extensive Energy Service Network in Europe, Middle East & Africa

|

|

|

|

|

|

|

|

|

|

Our clients

Customer focus through regional responsibility

Florian Wittfeld

Head of Sales &

Marketing

Mobil: +49 160 2924011

[email protected]

Tim Klein

Regional Sales Manager

North & West Europe

Mobil: +49 151 55717950

[email protected]

Heinz Wienen

Regional Sales Manager

East Europe & Turkey

Mobil: +49 160 98247135

[email protected]

Clemens Wolters

Regional Sales Manager

South Europe & Middle

East

Mobil: +49 171 7658586

[email protected]

Wolfgang Abeck

Regional Sales Manager

Africa

Mobil: +49 172 4575146

[email protected]

Thomas Pahnke

Regional Sales Manager

Germany, Austria, Switzerland

Sales Office Hannover

Mobil: +49 170 7055191

[email protected]