Waste-to-Energy (WtE)

Reutilisation of Waste through Thermal Waste Treatment

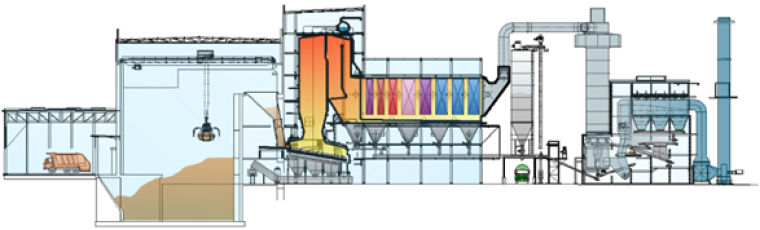

Environmentally friendly combustion of domestic waste, municipal waste, industrial waste, refuse derived fuel (RDF) and biomass fuels can be a powerful way for the reutilisation of waste. Energy conversion in thermal units is considered much more preferred to environmentally harmful disposal of waste in landfills.

Setting the Benchmark in Thermal Waste Treatment

Mitsubishi Power Europe has been developing thermal waste treatment technologies for more than 50 year and offers integrated solutions worldwide that are optimally machted and tailormade to meet our customers' individual requirements for solid waste materials up to 140 MWth and steam parameters up to 500°C - 100 bar.

The Waste-to-Energy solutions from Mitsubishi Power Europe help to replace fossil fuels and to reduce CO2-emissions while minimizing disposal limitations of organic residues.

Offerings

As a one-stop shop, Mitsubishi Power Europe supplies complete systems from waste input through to the flue gas discharge from the steam generator as well as acting as EPC contractor for complete Waste-to-Energy plants with consortium partners. Our range of services includes engineering, manufacturing, installation, commissioning, maintenance and servicing. Our after-sales service team takes complete care of your plant operation upon handover and offers full-service support on maintenance, repair, optimization and modernization.

Our Technology

- Up to 140 MWth and steam parameters up to 500°C - 100 bar

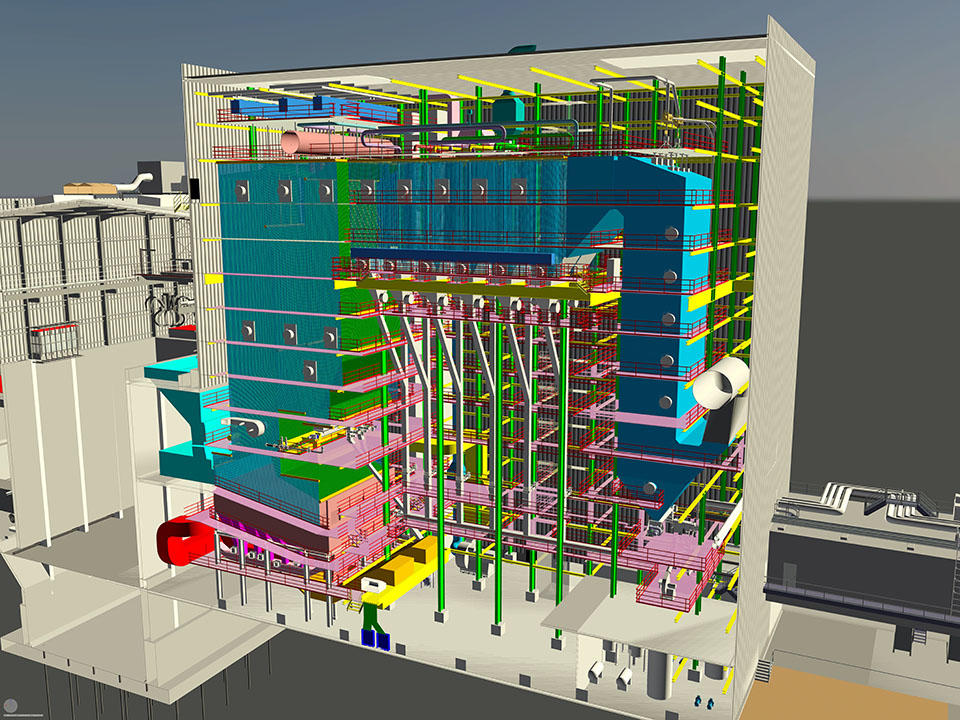

- Full integration including Auxiliary Components and Steelwork for boiler house

- Advanced Combustion Control System achieving the lowest emission requirements of the BREF BVT levels as well as high availability and long periods between cleaning shut-downs

- Flexible design options considering requirements of different flue gases treatment system

- Adaptable design for boiler house height or foot print restrictions

- Integrated easy and fast maintenance concept

- Advanced corrosion concept for highest availabilities.

- Standardized grate sizes with the possibility to switch later between water and air cooled grate bars in case of fuel switch

- Pre-erected grate modules for faster erection sequence (also optimized for retrofit jobs)

- Long lifetimes of grate bars

- Versatile possible types of fuels combustible with very high range of heating value (6-30 MJ/kg)

- High availability and reliability through robust design with proper mechanical and hydraulic power (no blockages)

- Full integration of he world leading Carob Capture System (all by a one-stop shop)

- Retrofitting of plants, after-sales components like grate bars, deslagger etc. as well as 24/7 Service and Long Term Service Agreements. For more information on our Service offering click here.

|

Andreas Rupp |