STEP1 Planning

Since establishing its ESP business in 1924, Mitsubishi Heavy Industries Power Environmental Solutions, Ltd. has delivered more than 3,200 ESP units across a broad range of industries.

Using the company's experience and know-how, we come together with the user and take full responsibility for all aspects of ESP implementation, including planning, design, construction, maintenance and renewal.

Proposal of ESP system that meets the user's needs by mobilizing the latest

- Tell Mitsubishi Heavy Industries Power Environmental Solutions, Ltd. about your needs and plans. We will help with the preparation of your plans.

- Following in-depth consultation, Mitsubishi Heavy Industries Power Environmental Solutions, Ltd. will draw up plans and propose an ESP system that meets your needs.

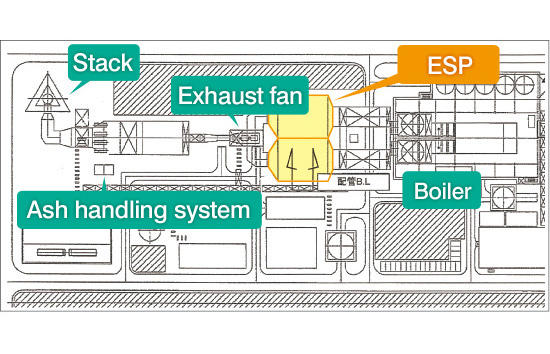

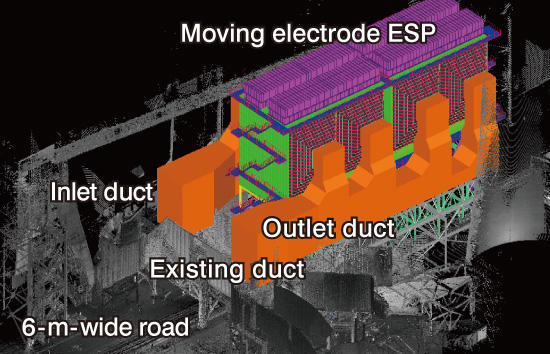

- A plan and basic design that aims for a space-saving, maintenance-free installation and an estimate of the cost will be prepared.

- A plan and design that conforms with the needed specifications, quality, and construction period will be completed.

- STEP1 Planning

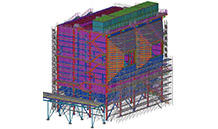

Proposal of ESP system that meets the user's needs by mobilizing the latest Computer Aided Engineering (CAE) technologies.

- STEP2 Fabrication and construction

Manufacture, fabrication and construction ensuring quality and short construction period with foremost priority on safety by mobilizing the latest CAE technologies and manufacturing/construction technical capabilities.

- STEP3 Inspection and commissioning

Inspection and field tests by a specialist in quality assurance, trial operation, adjustment, and handover.

- STEP4 Operation support and maintenance

Support for operation and maintenance provided with close attention by an assigned specialist.