Various Methods

Features of Fabric Filters

1. Reduces pressure loss

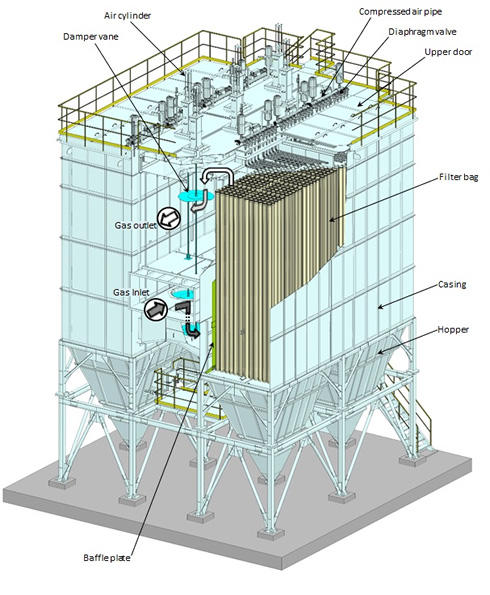

The treated gas flows in from the side wall of the dust collection compartment, and the gas flow is rectified by guide vanes and directed to the top part of the dust collection compartment.Dust of relatively coarse particle size contained in the gas is inertially separated by colliding with the baffle plates.The treated gas guided to the top part of the dust collection compartment flows down, and dust in the gas is filtered by filter cloths.

- The pressure drop at the filter cloth is reduced by inertial separation of coarse particles at the baffle plates to reduce dust concentration.

- The flow of the gas reduces the pressure drop of the filter cloth by making it easier for dust removed from the filter cloth to fall into the hopper and reducing re-scattering.

2. Extends filter cloth life

- Since the treated gas is dispersed from the top part of the dust collection compartment and flows down, the vibration caused by the air flow of the filter cloth is reduced and vibration fatigue of the filter cloth is reduced, so the life of the filter cloth is prolonged.

- The reduced pressure drop reduces the number of blowing compressed air and increases the life of the filter cloth.

- The combination of timer control and differential pressure detection control reduces fatigue degradation of the filter cloth by ensuring proper dust removal and stable pressure drop operation.

3. Uses highly airtight damper

We adopt unique high airtight damper to block airflow and bypass the dust collection compartment.High airtight dampers have a low gas leakage and are more airtight than normal dampers.

- The use of high airtight dampers in the bypass duct reduces leakage of treated gas and reduces outlet dust concentration.

- The use of high airtight dampers at the inlet of the dust collection compartment improves the removal effect of collected dust and reduces the pressure drop of the filter cloth.

4. Easy to maintain

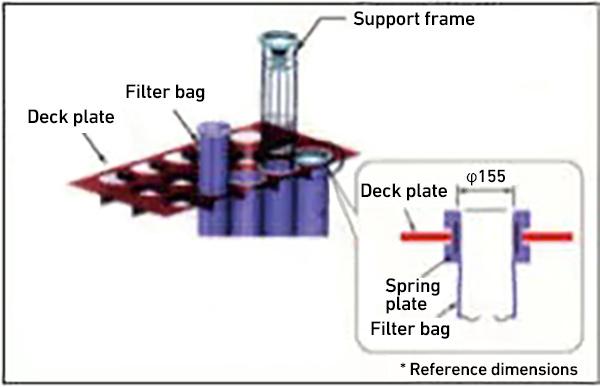

The spring plate fixing method, which make it easy to install and remove the filter cloth, is adopted, so that maintenance work can be speeded up.

- The retainer of the filter cloth can be divided, and it is easy to install and remove them.

- The ceiling of the dust collection compartment can be opened and closed with the help of workers, and it is easy to maintain without the need for hoists.

(In-house comparison)