Overview and Features

- Delivered units: More than 250.

- Accumulated volume of treated gas: More than 5,000,000 cubic meter/hour.

- Reliable technical strength and extensive experience help you to realize your VOC (volatile organic compound) reduction plan.

- Offering integrated services ranging from design, fabrication, and installation to after-sale service, allow us to build a long relationship with the customer.

* Content and system specifications shown on the website are subject to change without notice.

Features

Introduction of a Solvent Recovery System enables you to take measures for PRTR, VOC emission control, and global warming control, as well as conserve resources by reusing recovered solvents.

Safety Design

- An automatic operation system, which incorporates various safety interlocks, is employed (allowing safe and easy daily operation and control).

- For ketone solvents such as MEK (methyl ethyl ketone), all possible measures are incorporated such as a temperature-rising prevention (monitoring) system for the cooling process and water-injection system, etc.

High Performance

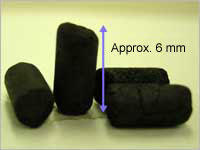

- Carefully processed granular activated carbon is employed, thus delivering a high collecting efficiency of 99 percent or more.

- Steam desorption controls decomposition of reactive solvents.

Durability and Low Running Costs

- Employing steam desorption and granular activated carbon contributes to a high purity-resistance and long service-life.

- Steam washes out impurities sticking to the activated carbon, which greatly improves durability.

Energy-Saving System

- Optimum design that adopts various automatic energy-saving systems tailored to operating conditions allows users to keep consumption of steam, electric power, and water to a minimum.

- Diverse options allow additional energy savings and use of exhaust heat recovery systems.

Recovered Solvent Purification/Separation

Solvents contained in the exhaust gas are not always of a single type.

Mixtures of solvents recovered by recovery equipment are separated and purified by means appropriate to the respective solvents properties.

Toluene + Acetone methanol

Some solvents are soluble. They are called "soluble solvents." What is dissolved in water is separated into water and recovered solvents by distillation.

For example, acetone and methanol are soluble in water. Acetone and methanol dissolved in the effluent are separated by distillation, using the difference in boiling point between the two.

Toluene + IPA

In order to recover solvents that are water-soluble and azerotropic with water, such as IPA (Isopropyl alcohol), from an effluent, a dehydration tower is required in addition to a distillation tower.

There are diverse methods for separating and purifying solvents according to type and composition We are open to finding solutions for combinations not mentioned. Please do not hesitate to contact us.