Principle of dust collection

Principles and structures of fabric filters

Fabric filter is a dust collection device that filters and collects dust in treated gas using woven or non-woven fabric called filter cloth. It is also called Bag Filter because the filter cloth is suspended in a cylindrical bag.

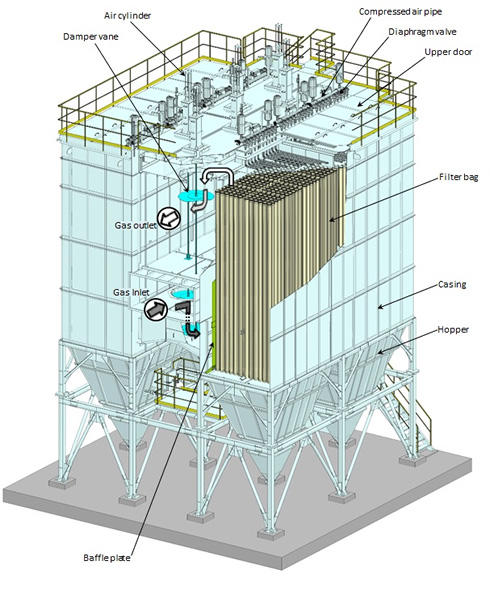

The inside of a large fabric filter is divided into several compartments. Each compartment contains several filter cloths and some hoppers at the bottom for collecting dust that has been stored. The fabric filter dust collection principle is to filter and collect dust in the processing gas at the dust layer (primary dust layer) deposited on and inside the filter cloth.

Normally the filtration velocity of the process gas passing through a filter cloth is about 0.3-2 m/min, and the pressure drop is about 1-2 kPa. As the dust layer collected on the surface of the filter cloth becomes thicker, the pressure loss of the filter cloth increases, so the collected dust is intermittently removed. The dust is removed by (1) passing gas from the back of the filter cloth (2) applying vibration. In most cases the dust collection efficiency of fabric filters is 99% or higher, and the dust concentration at the outlet is less than 10mg/m3N.

It is important to select the material of filter cloth to suit the gas temperature, humidity, gas composition, and dust characteristics.The life of a filter cloth is several years, but varies greatly depending on the gas and dust characteristics.The equipment cost of a fabric filter is lower than that of an electrostatic precipitator, but the maintenance cost of replacing the filter cloth, etc., and the operating cost of the system fan to compensate for the pressure drop is somewhat larger. Fabric filters are widely used as the dust collection systems for industrial processes with a medium or low quantity of process gas.

Dust removal methods

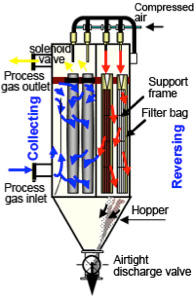

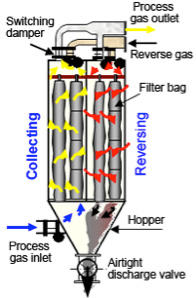

A fabric filter consists of several filter cloths sewn into cylindrical shapes and retainers that support the filter cloths. Process gas is filtered on the surface of the filter cloth, and the clean gas flows inside the filter cloth.

The collected dust is removed using the following methods: (1) Pulse-jet method, (2) Pulsative reverse air method. The structure and characteristics of these methods are described below. The Pulse-jet method has a filtration rate 1.3~1.6 times faster than the Pulsative reverse air method (our company ratio), allowing for smaller fabric filter size. The pulsative reverse air method uses a long filter cloth with a large-diameter opening, so it has the advantage of having a longer filter cloth life than the pulse-jet method.

| Dust removal methods | Pulse-jet method | Pulsative reverse air method | |

|---|---|---|---|

| structure |

|

|

|

|

|||

| Features | 1. Filtration speed | High speed | Medium speed |

| 2. Filter cloth size | Medium-length filter cloth with a medium-diameter opening | Long filter cloth with large-diameter opening | |

| 3. Filter cloth life | 2-4 years | 3-5 years | |

| 4. Pressure loss | About 1.5 kPa | About 1.5 kPa | |

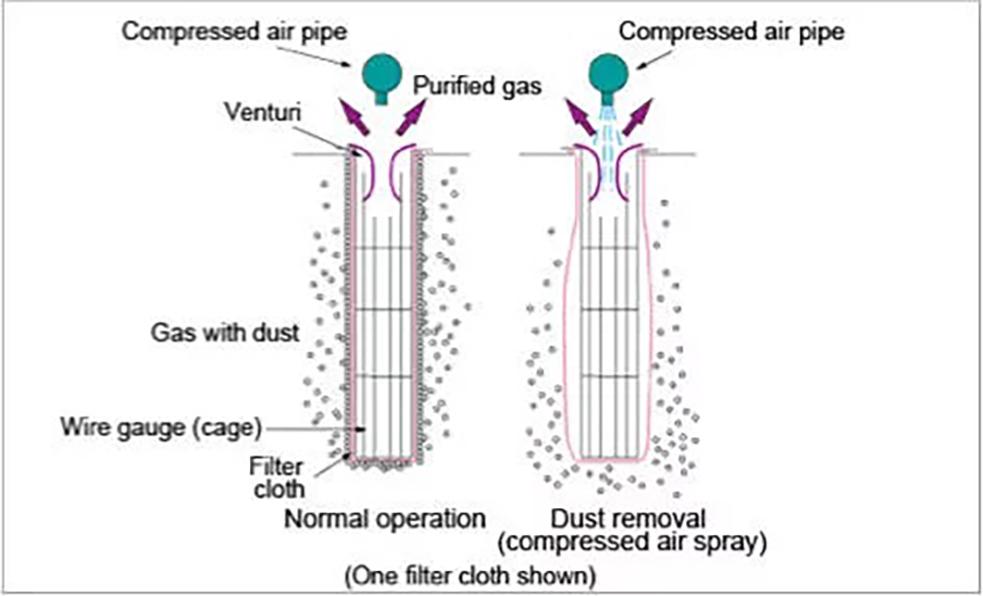

Pulse-jet type dust removal mechanism

Instantaneous injection of compressed air from the top of the filter cloth creates a pulsed jet stream that removes dust that has deposited on the surface of the filter cloth.