High-Speed Coagulating Sedimentation Equipment

It is capable of approximately five times faster treatment than the conventional Coagulating-sedimentation treatment.

High-Speed Coagulating Sedimentation Equipment

In the area of SS separation and removal from various types of wastewater, there is a growing need among users to save space and labor.

Mitsubishi Heavy Industries Power Environmental Solutions, Ltd. has developed a system capable of high-speed treatment approximately five times faster than conventional Coagulating-sedimentation treatment systems.

System overview

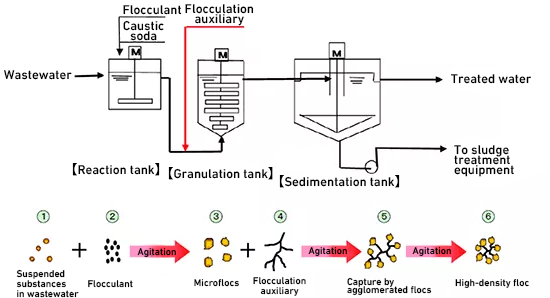

- Flocculation process

Flocs are formed through selection of an appropriate flocculant depending on the properties of the wastewater. - Granulation process

By optimizing the method of flocculation auxiliary injection and the agitation period, the formed flocs are turned into high-density flocs. - Sedimentation and clarification process

A slurry blanket layer is formed to increase the sedimentation rate of the high-density flocs.

Features

- Compact size

Capable of high flow rate treatment (5 m/hr).

Small installation area of less than half that of conventional systems.

Confirmation is made in laboratory tests using actual wastewater. - High performance

Microflocs are captured by the slurry blanket layer to suppress carryover. - No need for sludge thickener

The sludge is consolidated and concentrated to a high concentration (approximately 30,000 mg/L). However, the concentration of sludge varies depending on the wastewater.

Applications

- SS removal from various types of wastewater

- Capacity enhancement of existing Coagulating-sedimentation systems

- Renewal of existing Coagulating-sedimentation systems

Products

- Electrostatic Precipitator

- Fabric filters

- Tunnel Electrostatic Precipitator

- Organic Solvent Exhaust Gas Treatment System

- Water Treatment

- Wastewater Treatment System