Two-Phase Activated Sludge System

It can simultaneously increase processing capacity and reduce sludge.

Two-Phase Activated Sludge System

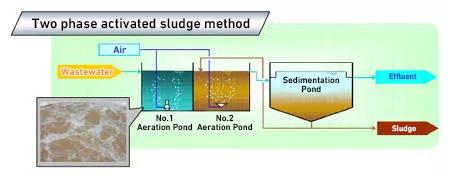

It can be achieved by modifying only a part of the existing aeration tank, and does not require installation of a new water tank.

Operation management is easy without addition of new utilities, etc.

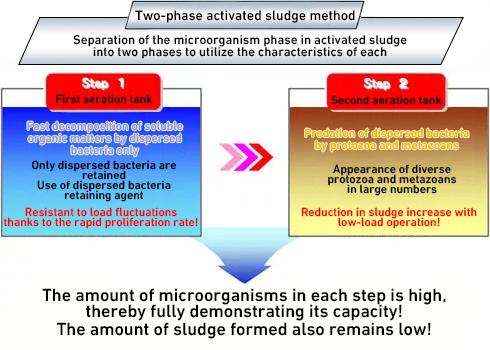

System overview

- Processing capacity can be increased with simple modification of the existing aeration tank

Fast decomposition of organic matter by dispersed bacteria. Significant increase in processing capacity (results of 30% or more). - Sludge amount can be reduced

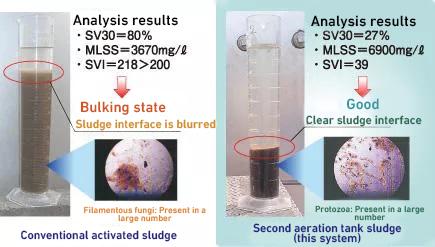

Sludge reduction results in actual machines: 60 to 80% - Less susceptible to bulking

- Resistant to load fluctuations

Dispersed bacteria proliferate rapidly (at least 10 times that of activated sludge) and can follow the load fluctuations.

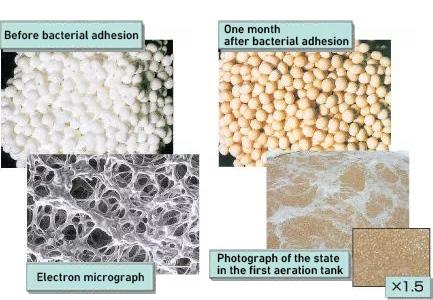

Dispersed bacteria retaining material

Two-phase carrier method

System introduction flow

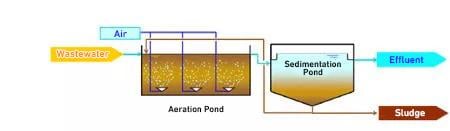

Conventional

This system

Introduction case example

Industry type: Wastewater from manufacturing plant for seasoning, etc.

| Existing | After modification | |

|---|---|---|

| Water treatment quantity | 640m3/d | 720m3/d (maximum of 840m3/d) |

| BOD concentration in raw water | 1500mg/L | 1500mg/L |

| BOD concentration in treated water | 25mg/L or less | 25mg/L or less |

| Sludge SVI | 200 or higher | Around 40 |

| Sludge generation rate (organic) | 100% | 20~40% (Achieve reduction by 60 to 80%) |

Example improvement achieved by system introduction

Products

- Electrostatic Precipitator

- Fabric filters

- Tunnel Electrostatic Precipitator

- Organic Solvent Exhaust Gas Treatment System

- Water Treatment

- Wastewater Treatment System