Mitsubishi Shipbuilding and MHPS Launch Advanced SOx abatement system ACTIVE FUNNEL -- Excellent Desulfurization Capacity with Efficient Use of Space, Suitable for Very Large Container Ships --

Mitsubishi Shipbuilding Co., Ltd.

Mitsubishi Hitachi Power Systems, Ltd.

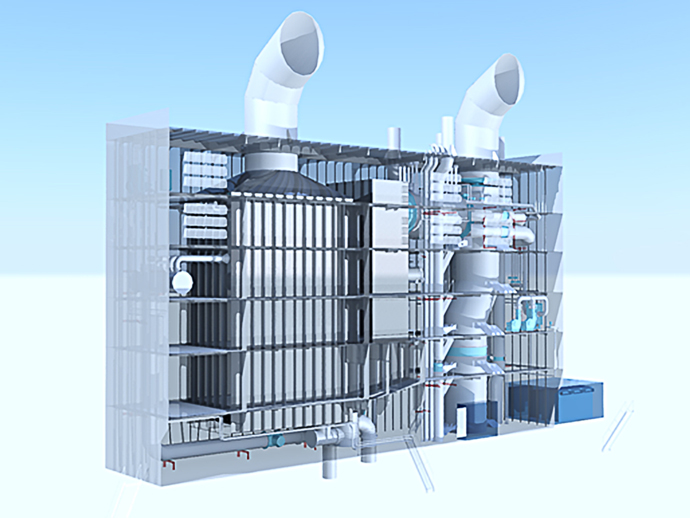

YOKOHAMA, JAPAN (May 31, 2018) - Mitsubishi Shipbuilding Co., Ltd. (Mitsubishi Shipbuilding) and Mitsubishi Hitachi Power Systems, Ltd. (MHPS) have jointly launched the most advanced SOx abatement system, ACTIVE FUNNEL. It is a funnel which contains an optimally shaped exhaust gas scrubbing structure which reduces sulfur dioxide (SO2) in the exhaust gas of 3.5%-sulfur-content fuels to that of 0.1%-sulfur-content fuels, conforming with newly introduced SOx emissions regulations coming into effect globally as of January 1, 2020.

The new and reliable SOx abatement system was developed by combining MHPS' comprehensive exhaust gas treatment technologies cultivated through providing desulfurization systems for thermal power plants with Mitsubishi Shipbuilding's marine engineering expertise which has been developed through its long shipbuilding experience. MHPS' land-based flue gas desulfurization systems have the capacity to treat the equivalent of 7 to 20 times of the emissions from a large size marine diesel engine.

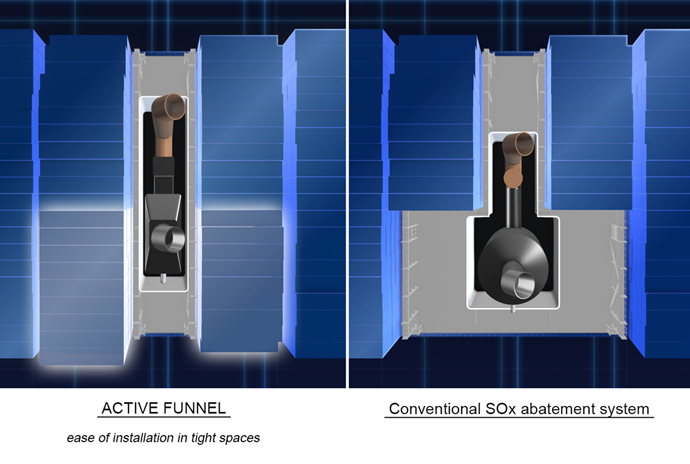

The ACTIVE FUNNEL is most suitable for very large container ships with high exhaust gas emissions and limited installation space for SOx abatement systems. It can desulfurize large amounts of exhaust gas and its flexible design makes it possible to be installed even in narrow spaces between the container holds, while maintaining a vessel’s container capacity. The ACTIVE FUNNEL is also suitable for installation on existing ships since it is provided as one module and has a short retrofitting period.

The ACTIVE FUNNEL which is applicable to both open-loop systems and hybrid systems(Note1) provides a traditional funnel with advanced SOx removal function.

Going forward, the product lineup will be expanded by applying the new ACTIVE FUNNEL technology to very large crude carriers (VLCC: 200,000-310,000 DWT(Note2)) and very large ore carriers (VLOC).

When new SOx emissions regulations come into effect, the ACTIVE FUNNEL is expected to contribute to the further development of environmentally-friendly and economic global marine transportation .

- 1In an open-loop system, seawater intake is sprayed directly on the exhaust gas and then discharged from the ship. In a closed-loop system, the exhaust gas is scrubbed using circulating water, after which the circulating water is neutralized for reuse. In a hybrid system, it is possible to switch between the open and closed systems.

- 2DWT = dead weight tonnage

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, logistics & infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on www.spectra.mhi.com.