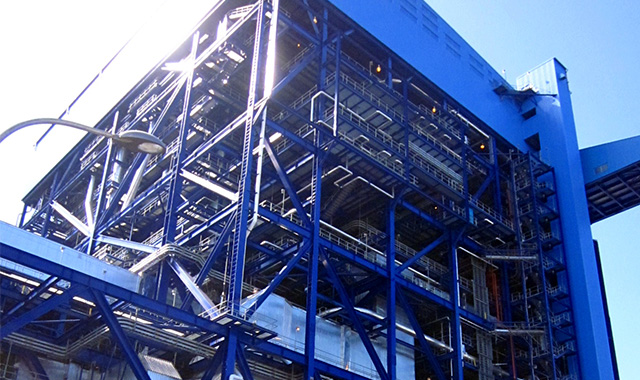

Boilers

Power Uprating

Mitsubishi Power offers solutions for power uprating by maximizing equipment utilization ability.

We also offer output recovery for plants where present output cannot achieve original maximum output due to aged degradation.

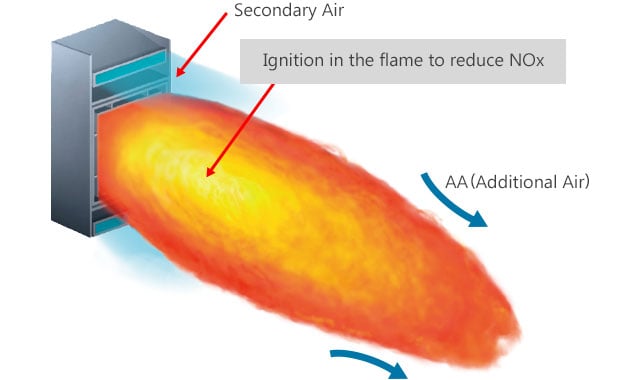

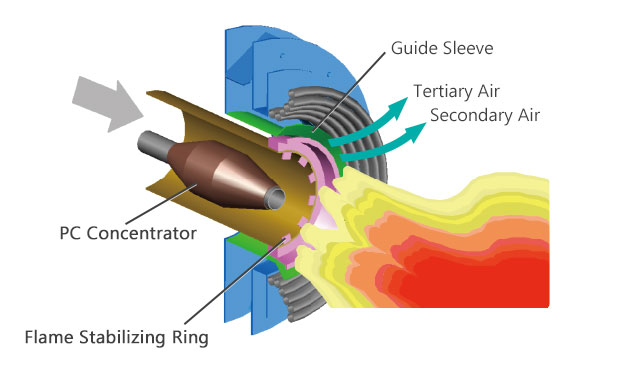

High Performance Burner Replacement

Through technological advancements, Mitsubishi Power high-performance burners realize lower NOx emission and less unburned coal than former burners.

These high-performance burners satisfy environmental regulations and are applicable to a wide variety of coals.

Mitsubishi Power possesses both corner-firing and opposed-firing technologies to meet diversified customer needs.

PM Burner

NR Burner

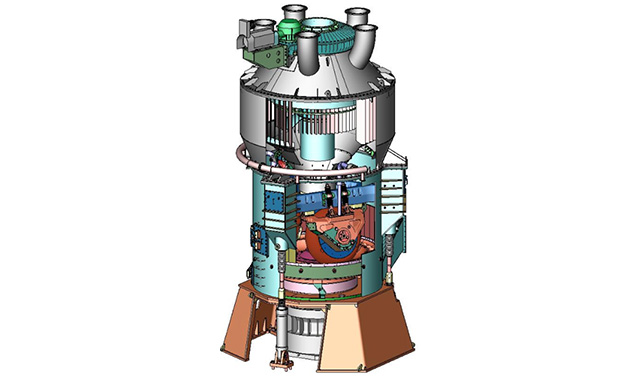

High Performance Mill Replacement

In order to meet coal variations and to optimize combustion, mills are important equipment for pulverized boilers. High-performance mills offer outstanding pulverization and classification and promise lower unburned carbon, more variety of coals, and higher ratio of co-fired biomass fuels.

Shortening Periodical Inspections

We propose plant equipment modifications for shorter inspection periods. For example, an advanced work platform inside the boiler can be useful for removing clinker and enable easy access to suspended tubes. Also, using it as scaffolding periodical inspections has been instrumental in shortening inspection time.

Moreover, replacement to necktie-type suspended tubes can decrease the amount of clinker deposits in some boilers.

Clinker removal using advanced work platform Hitachinaka Thermal Power Station Unit2

(Source:JERA Co.,Inc).

Retrofitting Pressure Parts

Over long-term operations, the dependability of boiler pressure parts decreases, lessening the reliability of the entire plant. we have developed risk-based maintenance (RBM) procedures using inspection results on each part of the boiler to determine weak points of pressure parts and have introduced planned maintenance programs based on these results. For deteriorated boilers, we have recommended that customer use the RMB procedures in order to reduce unplanned shutdowns.

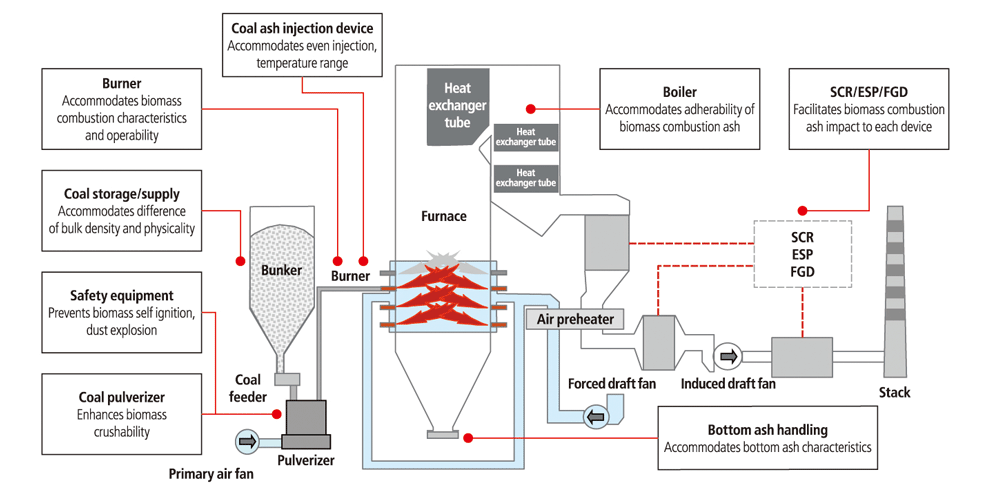

Biomass Fuel-fired Boilers

A wide range of biomass mixed co-firing rates can be realized by applying coal/biomass dual system (coal pulverizer/burner) to coal-fired power generation technologies. Biomass co-firing rates can be adjusted without major changes of equipment. In addition, it is possible to have 100% biomass firing in a boiler by adding a small amount of coal ash. Mitsubishi Power has a proven track record in biomass firing modification of 350 MW-class power plant.

Special Inspection Technologies ―Cable-less Inner UT ―

For finned economizer tubes, it is very difficult to inspect tube thickness. We offer a cable-less inner UT system for these inspections. By running a special sensor through the tubes, thickness can be measured along the tube length of economizers and other heat exchanger tubes.

Maintenance of CSEF Steels

It is important to maintain pressure parts that use creep strength enhanced ferritic (CSEF) steels. High-performance power plants are seeing a significant increase in the application of CSEF steels these days, while the properties of CSEF steels continue to be clarified through recent experience and investigated data. The ASME Codes covering CSEF steels have been revised on the basis of these experience and data. For example, application of weld strength reduction factors (WSRF) of CSEF steels (ASME, Section I, PG-26) is a key revisions, because creep strength of the welded joints of CSEF steels was found to have a weaker than previously estimated value. Japan's domestic rules regarding CSEF steels have also been revised several times by the Ministry of Economy, Trade and Industry (METI). In 2014, for example, life time evaluation formulas of creep rupture property for high chromium steels*1 have been revised. Based on the recent technical information regarding CSEF steels as mentioned above, Mitsubishi Power recommends periodical inspection and maintenance for the pressure parts using CSEF steels.

- High chromium steels are included in CSEF steels.