Delivery Results

Mitsubishi Power has delivered a wide range of air quality control systems around the world in the fields of electric power and industry.Here we introduce one such example.

-

Coal-fired Boiler Application (High Dust)

Customer JERA Co.,Inc. Plant

(Country)Hitachinaka Thermal Power Station Unit 2 (Japan) Fuel Coal

Output 1,000 MW

Start of operation December 2013

-

Coal-fired Boiler Application (Low Dust)

Customer Electric Power Development Co., Ltd. Plant

(Country)Matsuura Thermal Power Station Units 1 and 2 (Japan) Fuel Coal

Output 1,000 MW

Start of operation Unit 1: 1990, Unit 2: 1997

-

Coal-fired Boiler Application (High Dust)

Customer Seminole Electric Co., Inc. Plant

(Country)Seminole Generating Station Units 1 and 2 (United States) Fuel Coal

Output 650 MW

Start of operation April 2009

-

Coal-fired Tower Boiler Application (High Dust)

Customer Evonik Plant

(Country)Walsum Unit 10 (Germany) Fuel Coal

Output 750 MW

Start of operation 2013

-

Coal-fired Boiler Application

Customer Hidroeléctrica del Cantabrico S.A. Plant

(Country)Aboño PS Unit 2 (Spain) Fuel Coal

Output 556 MW

Start of operation January 2017

-

Coal-fired Boiler Application

Customer Hidroeléctrica del Cantabrico S.A. Plant

(Country)Soto PS No.3 (Spain) Fuel Coal

Output 361 MW

Start of operation July 2017

-

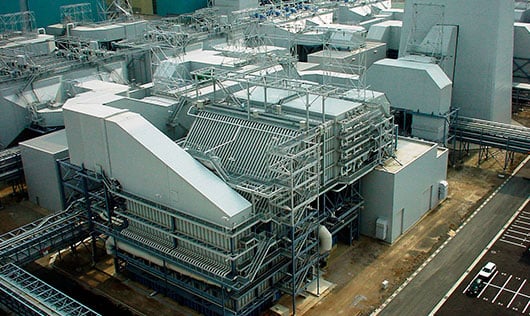

Gas Turbine Combined Cycle (GTCC) Application

Customer JERA Co.,Inc. Plant

(Country)Joetsu Thermal Power Station 1-1 and 1-2 (Japan) Fuel Natural gas

Output 1,190 MW

Start of operation 2012/2013

-

High Sulfur-content Fuel-fired Boiler Application

Customer Mitsubishi Chemical Corporation Plant

(Country)Mizushima Plant No. 3 Boiler (Japan) Fuel SDA pitch

Output (450t/h)

Start of operation July 2009

-

Internal Combustion Engine Application

Customer JERA Co.,Inc. Plant

(Country)Hitachinaka Thermal Power Station (Japan) Fuel Light oil

Output 253 MW

Start of operation July 2011

-

Customer Electric Power Development Co., Ltd. Plant

(Country)Tachibanawan Power Station Unit 1 (Japan) Fuel Coal

Output 1,050 MW

Start of operation July 2000

-

Customer JERA Co.,Inc. Plant

(Country)Hitachinaka Thermal Power Station Unit 2 (Japan) Fuel Coal

Output 1,000 MW

Start of operation December 2013

-

Customer Electrownia Kozienice S.A. Plant

(Country)Kozienice Power Station Units 3 - 6 (Poland) Fuel Coal

Output Equivalent to 800 MW (200 MW × 4)

Start of operation December 2006

Features Wet Stack Tower Application

-

Customer Frontier Energy Niigata Co., Ltd. Plant

(Country)Niigata Power Plant (Japan) Fuel Petroleum coke

Output 110 MW

Start of operation July 2005

Features Treat High Sulfur Special Fuel

-

Customer Endesa Generation S.A. Plant

(Country)Teruel Units 1 - 3 (Spain) Fuel Lignite

Output 350 MW × 3

Start of operation October 1999

-

Customer Shikoku Electric Power Co., Inc. Plant

(Country)Sakaide Thermal Power Station Unit 3 (Japan) Fuel Heavy oil

Output 450 MW

Start of operation March 2003

-

Customer Empresa Electrica Guacolda S.A. Plant

(Country)Guacolda Unit 3 (Chile) Fuel Coal, petroleum coke

Output 150 MW

Start of operation July 2009

Features Treat High Sulfur Special Fuel

-

Customer Hokkaido Electric Power Co., Inc. Plant

(Country)Shiriuchi Power Station Unit 2 (Japan) Fuel Orimulsion, heavy oil

Output 350 MW

Start of operation September 1998

Features Treat High Sulfur Special Fuel

-

Customer PT. Paiton Energy Plant

(Country)Paiton Ⅲ Thermal Power Plant (Indonesia) Fuel Coal

Output 856 MW

Start of operation April 2012

Features Seawater FGD

-

Customer Shuqaiq Water and Electricity Co. Plant

(Country)Shuqaiq IWPP Units 1 - 3 (Saudi Arabia) Fuel Heavy oil

Output 340 MW × 3

Start of operation April 2010

Features Seawater FGD

-

Customer Pagbilao Energy Corp. Plant

(Country)Pagbilao Power Station Unit 3 (Philippines) Fuel Coal

Output 420 MW

Start of operation February 2018

Features Seawater FGD

-

FGD Wastewater Treatment

Customer Vietnam Electricity Plant

(Country)O Mon Thermal Power Plant Unit 1 (Vietnam) Fuel Heavy oil

Output 330 MW

Capacity 49 m3/h

Start of operation July 2009

-

High-speed Sedimentation

Customer Electric Power Development Co., Ltd. Plant

(Country)Tachibanawan Power Station Units 1 and 2 (Japan) Fuel Coal

Capacity 30 m3/h

Start of operation February 2014

-

Biological De-Nitrification and Selenium Treatment

Customer Sumitomo Joint Electric Power Co., Ltd. Plant

(Country)Niihamanishi Thermal Power Plant Unit 3 (Japan) Fuel Coal

Output 150 MW

Capacity 29.8 m3/h

Start of operation January 2008

-

Heavy Metal Removal

Customer Kashima-kita Electric Power Corporation Plant

(Country)Kashima-kita Joint Power Plant Unit 1 (Japan) Fuel Heavy oil

Output 250 MW

Capacity 2.3 m3/h

Start of operation April 1992

-

Sedimentation and Biological De-Nitrification Treatment

Customer Nakayama Nagoya Joint Power Generation Co., Ltd. Plant

(Country)Nagoya Power Plant Unit 1 (Japan) Fuel Coal

Output 149 MW

Capacity 5 m3/h

Start of operation April 2000

-

Oil Separation

Customer Tohoku Electric Power Co., Inc. Plant

(Country)Akita Thermal Power Plant (Japan) Fuel Heavy oil

Capacity 20 m3/h

Start of operation June 2006

-

Ash and Wastewater Mixture Treatment (AWMT)

Customer Yokkaichi Kasumi Power Co., Ltd. Plant

(Country)Yokkaichi Kasumi Power Station (Japan) Fuel Vacuum Residue

Output 223 MW

Capacity 3.7 ton/h

Start of operation April 2003

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report