Products

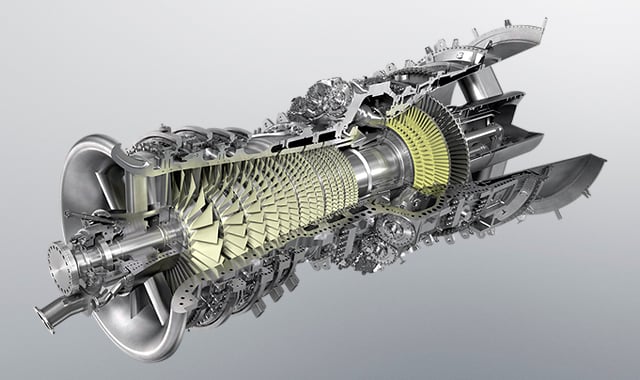

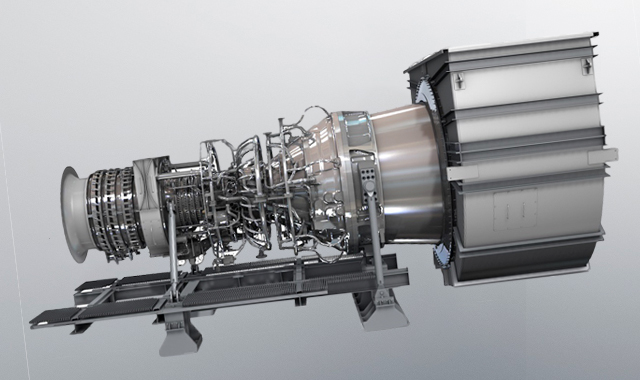

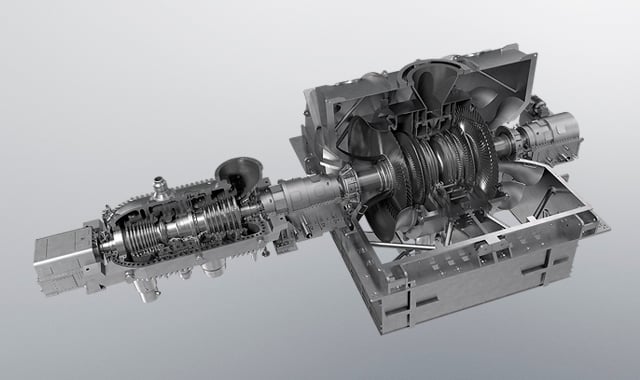

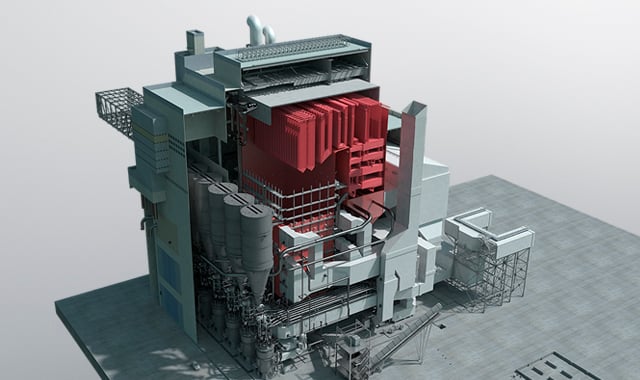

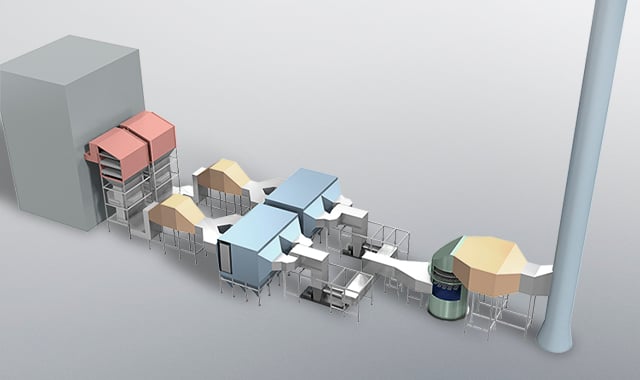

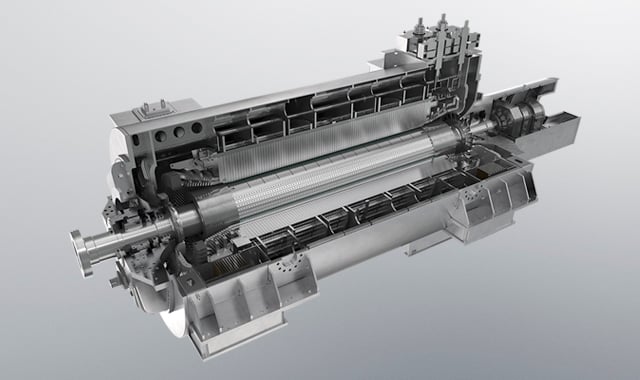

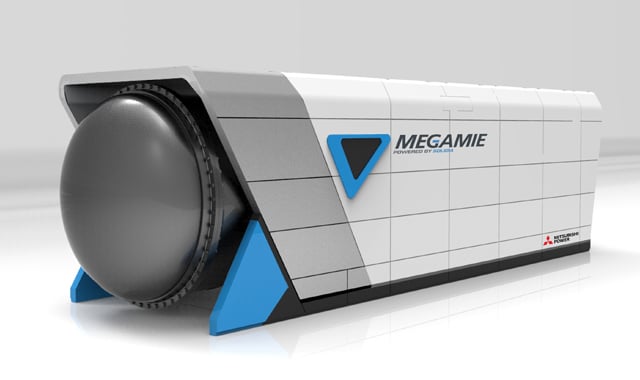

Mitsubishi Power offers a range of power plants tailored to different applications and sizes. Our power plants are well regarded for their high reliability as well as for their exceptional operability and ease of maintenance. Accordingly, Mitsubishi Power has developed an extensive track record through numerous projects around the globe.