What is DIASYS?

The Digital Intelligent Automation SYStem, or DIASYS, is a distributed control system (DCS) developed to maximize plant performance while offering high reliability and utilization rates.

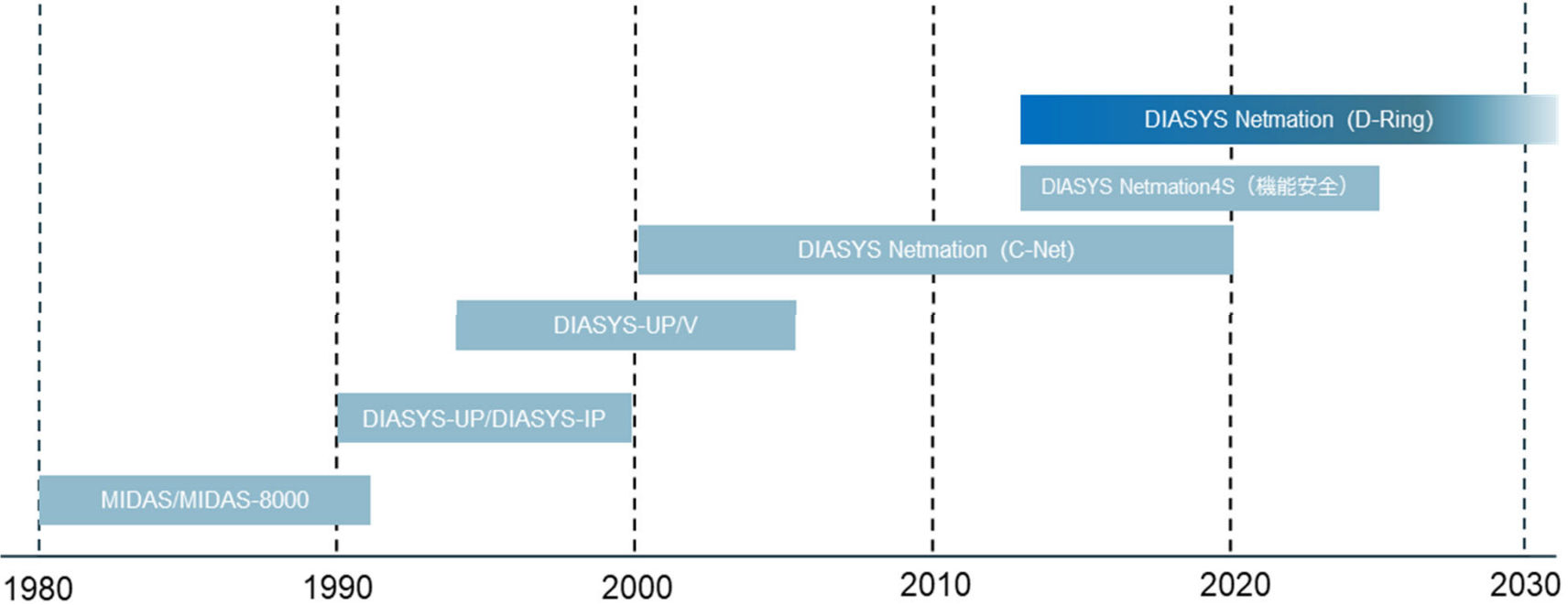

The DIASYS series, developed as a control system for thermal power plants in the 1980s, has been adopted in more than 2,800 projects to date and boasts a delivery track record spanning more than 60 countries (As of End of December 2023).

DIASYS Netmation, which was released in 2000, has been highly regarded for the high reliability of its control equipment, and its user-oriented operational monitoring and engineering tools. The solution is not just a great fit for thermal power plants; it also works as a control and monitoring system for a variety of facilities and products, including rocket launch facilities, LNG carriers, plant management systems and office building management systems.

Mitsubishi Power has also released a secure gateway to support the development of secure systems even on open networks, making it easier to collect data for customer value creation utilizing the latest ICT including remote equipment monitoring and preventative maintenance.

With a lineup that caters to everything from small to large systems and from equipment control and monitoring to protective functions, the DIASYS series goes a step further in contributing to customer businesses.

Please check the related links to learn more about our latest control systems, DIASYS Netmation.

-

Related Links

- DIASYS Netmation

- DIASYS Netmation4S(Note)

- In 2024, we stopped providing SIL-compatible systems that have obtained certification under the functional safety standard (IEC61508) due to difficulties in obtaining electronic components.

Since then, we have only been able to support the maintenance of delivered products.

If you would like a SIL-compatible system, we can provide another system

History of the DIASYS Series

The DIASYS has its roots in a system that used a DEC mini-computer at the beginning of the 1980s. In the late 1980s, a single-board computer manufactured by Intel was adopted to develop a direct digital control (DDC) system.

At the same time, Mitsubishi Power developed the original Interpreter DDC Oriented Language (IDOL) as a tool for creating a Program Oriented Language (POL). Through soft updates and support for various platforms (DOS, Unix, Linux and Windows-based systems), IDOL is still used to this day.

Around 1990, Mitsubishi Power developed its own control modules to replace the modules it had mostly been purchasing externally. Using CPU modules that employed the latest 32-bit CPUs of the day (M386CPU), Mitsubishi Power updated almost all of the modules and power supply units used in its control equipment.

At the time, Mitsubishi Power had already been designing and fabricating control boards in-house, and progressed to the in-house production of the modules from this point forward.

Later, in the late 1990s and early 2000s, Mitsubishi Power undertook two major revamps of its control equipment, At present, we provide DIASYS Netmation (D-Ring) using "D-Ring," a high-speed and highly reliable field network.

Track Record of Deliveries

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report