DIASYS Netmation

Overview

All elements related to plant control including design, operation, monitoring, maintenance and backups are controlled using computers and communications technologies.

With DIASYS Netmation, devices can be selected based on system size to develop an optimum system configuration.

- Among the DIASYS Netmation lineup, we discontinued the DIASYS Netmation (C-Net) system, which uses Allen-Bradley ControlNet technology for the IO fieldbus, in 2020.

Currently, we offer the DIASYS Netmation (D-Ring) system, which uses our proprietary D-Ring network technology with higher speed and reliability.

Features

Features of DIASYS Netmation

- High reliability

High reliability achieved through thorough design theory and a stringent quality control system integrates main plant equipment to provide comprehensive support. - Advanced control functions

32-Bit processors, high-speed networks and extensive process I/O modules demonstrate excellent controllability. - Excellent operability

The ergonomically designed human interface provides a comfortable operating environment for users. - Easy maintenance

Thanks to the superior user interface of the ORCA-View maintenance software, dramatic improvements are made to operability during maintenance management. - Flexibility and expandability

From small to large-scale systems, a wide range of applications are supported regardless of size, and system expansion in the future is also a simple matter.

Control Equipment that Makes Up DIASYS Netmation

-

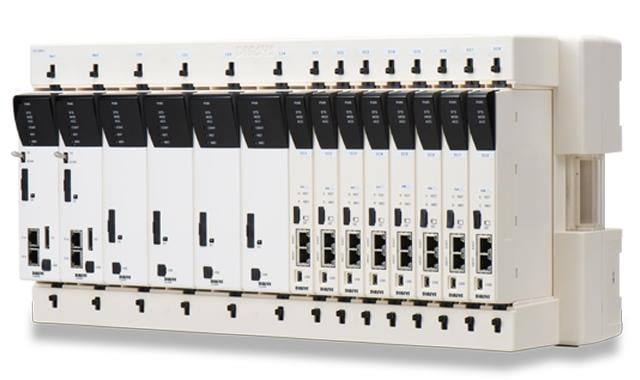

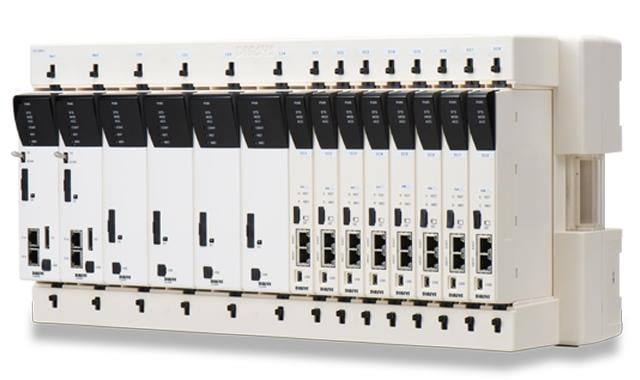

Multiple Process Station (MPS)

This control equipment performs plant control operation and site ON/OFF control.

-

Compact Process Station (CPS)

This control equipment is used for I/O with instruments and other equipment installed on-site at the plant, automated plant control, and various computational processing.

- The Compact Process Station (CPS) was discontinued in 2020 as a dedicated equipment for DIASYS Netmation (C-Net).

-

Dependable Process Station (DPS)

This control equipment can be used as a process control or interlock system.

-

Netnode Process Station (NPS)

This control equipment is used for I/O with instruments and other equipment installed on-site at the plant, automated plant control, and various computational processing.

-

Multiple Process Station (MPS)

This control equipment performs plant control operation and site ON/OFF control.

-

Compact Process Station (CPS)

This control equipment is used for I/O with instruments and other equipment installed on-site at the plant, automated plant control, and various computational processing.

- The Compact Process Station (CPS) was discontinued in 2020 as a dedicated equipment for DIASYS Netmation (C-Net).

-

Dependable Process Station (DPS)

This control equipment can be used as a process control or interlock system.

-

Netnode Process Station (NPS)

This control equipment is used for I/O with instruments and other equipment installed on-site at the plant, automated plant control, and various computational processing.

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report