Demonstration Project for Fuel Cell Power Using Biogas from Brewery Wastewater

-- Final testing for practical application of new technology to reduce CO2 emissions --

-- Final testing for practical application of new technology to reduce CO2 emissions --

Asahi Group Holdings, Ltd.

Mitsubishi Hitachi Power Systems, Ltd.

Sumitomo Mitsui Finance and Leasing Co., Ltd.

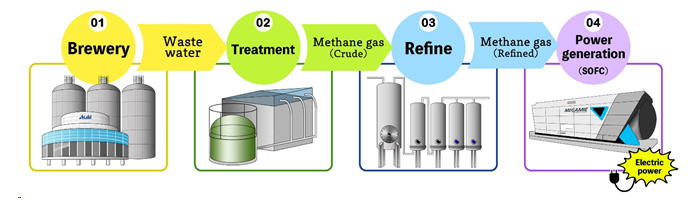

Asahi Quality & Innovations, Ltd., an independent research subsidiary of Asahi Group Holdings, Ltd., has begun a demonstration project at the Asahi Breweries, Ltd., Ibaraki Brewery generate power from fuel cells utilizing bio-methane gas (“biogas”) derived from the brewery's wastewater, which will establish a new model for reducing CO2 emissions. Mitsubishi Hitachi Power Systems, Ltd. (MHPS) has provided its MEGAMIE solid oxide fuel cell (SOFC) system for the project. Sumitomo Mitsui Finance and Leasing Co., Ltd. (SMFL) is providing financing for the project through a lease scheme.

The demonstration project is being conducted as part of the Japanese government's Low Carbon Technology Research, Development and Demonstration Program, with subsidies from the Ministry of the Environment for projects that contribute to reducing CO2 emissions. SMFL is coordinating the project as lead applicant. Once in operation, the facility with power output of 200 kilowatts (kW) will be capable of supplying around 1,600 (MWh) of power annually (sufficient to power 350 ordinary households), with projected reductions in CO2 emissions of around 1,000 tonnes per year.

The system is scheduled to begin operations in October 2020.

(Left rear: Brewery wastewater treatment facility; Center: Biogas refining equipment; Right front: SOFC)

Final test for practical application of new plant technology to reduce CO2 emissions

Asahi Group, with the aim of reducing CO2 emissions, has been working to introduce power generation facilities utilizing high energy conversion efficiency fuel cells to secure base electricity power to operate its factories. By June 2018 the company had developed a process to refine the biogas generated during the treatment of brewery wastewater to a high purity, allowing it to be utilized as the power source with carbon neutral fuel cells. The company conducted tests to generate power with small SOFCs using this refined biogas, and in May 2019 successfully generated power continuously for 10,000 hours.

Asahi Group has now begun the final stage of testing for practical application with the installation in the Ibaraki Brewery of a MEGAMIE SOFC system from MHPS, offering world-class power generating efficiency. MEGAMIE, which was made available for commercial applications in 2017, uses ordinary city gas as fuel to produce clean electric power and heat with low CO2 emissions. This project is the first application using biogas derived from brewery wastewater as fuel. Combining the system with biogas refining equipment is expected to provide a significant reduction in CO2 emissions.

By the time the project is completed, Asahi Group expects to establish the technology to generate power from fuel cells using biogas obtained from brewery wastewater as the fuel source.

Specific measures to implement the technology in society

Asahi Group and its partner companies are also considering specific plans to implement this technology in society.

To promote the widespread utilization of this technology in the foods and related industries, Asahi Group has decided not to seek patents for the necessary refining technologies and equipment that it has acquired from this demonstration project, and instead will make the information available as much as possible.

MHPS, based on the data acquired from the demonstration experiment, will seek to expand use of this system at breweries and other facilities able to utilize other types of untapped energy sources. The company will also work to further enhance the performance and convenience of MEGAMIE, and provide energy generation to support the realization of a decarbonized society.

SMFL, through leasing and other types of financial services, will support the greater adoption of fuel cells by providing capital for plant investment and curbing startup costs.

Asahi Group, MHPS, and SMFL will utilize their respective strengths to develop and support the widespread adoption of SOFC and other technologies to curb CO2 emissions, and contribute to the realization of a sustainable global environment.

Reference: Environmental measures at Asahi Group, MHPS, and SMFL

Asahi Group has adopted “Contribute to a sustainable society through our business” as one of the principles of the Asahi Group Philosophy. Further, in its Asahi Group Environmental Vision 2050, Asahi Group has set a longer-term goal for curbing greenhouse gas emissions to address climate change, called Asahi Carbon Zero, which seeks to eliminate all greenhouse gas emissions by 2050. As a part of its measures for achieving the Asahi Carbon Zero target, the group has previously introduced and conducted demonstration testing of a stand-alone hydrogen energy supply system, and CO2 separation and collection testing equipment. Going forward, as a company that conducts business supported by the “blessings of nature,” Asahi Group will proactively pursue a range of environmental measures to ensure that these blessings of nature are passed on to the next generation.

MHPS, based on its corporate philosophy of contributing to society through outstanding products and services, has provided customers around the world with numerous products that support high-efficiency power generating systems, the effective utilization of resources, and a reduced environmental impact. These efforts contribute to the stable supply of electric power, as well as economic development with a lower environmental load.

SMFL offers a range of financial services and joint application for subsidies to support investment in renewable energy and energy-efficient equipment. The company has also entered the renewable energy power generation business, and has an on-site, captive consumption solar power service. By providing various solutions to support the widespread adoption of clean energy and decarbonized business operations, SMFL is working to prevent global warming and realize a recycling-based society.

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, logistics & infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on www.spectra.mhi.com.