MHI is Awarded a Major Turbomachinery Order for Ust-Luga LNG Export Plant

· MHI is selected as a key equipment supplier for the world scale 13 million ton per annum (mtpa) LNG project

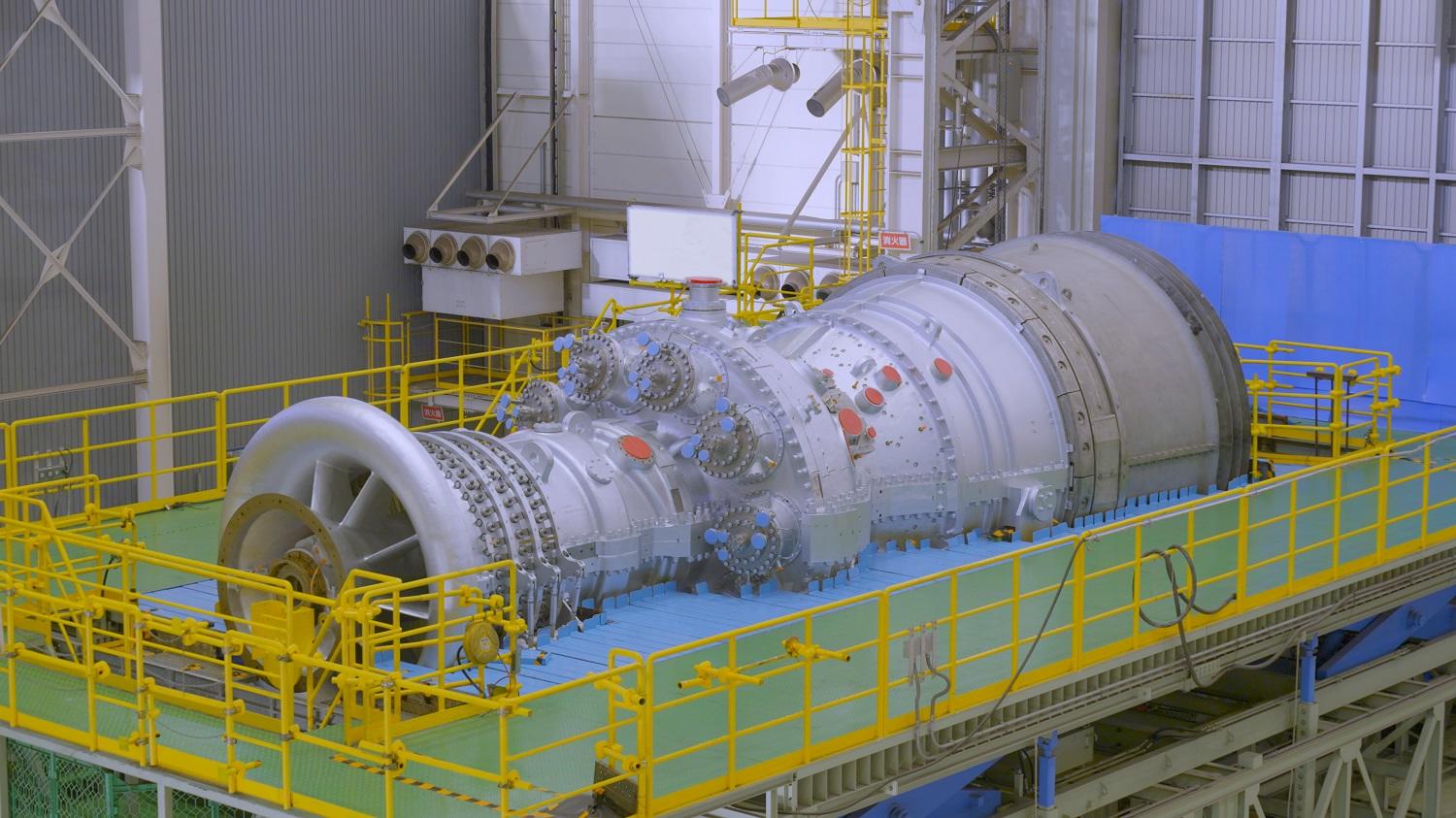

· The order for the main refrigeration gas compression trains consists of 4 H-100 gas turbines and 10 centrifugal compressors

· MHI's innovative highly efficient dual shaft gas turbine technology enables a step-change reduction in equipment and plant emissions

Tokyo, November 25, 2021 - Mitsubishi Heavy Industries, Ltd. (MHI) announced today that MHI has been awarded by Linde Engineering the main refrigeration gas compression trains for the Ust-Luga LNG project in Russia. The order consists of the best in class, high efficiency dual shaft 120 megawatt H-100 gas turbines and centrifugal compressors.

Led by RusChemAlliance LLC, the 50-50 special-purpose venture of PJSC Gazprom and JSC RusGazDobycha, the Ust-Luga LNG project is a world class natural gas liquefaction plant designed to apply the liquefaction technology owned by Linde and Gazprom, with two trains to produce upwards of 13 million tons per annum (mtpa). The liquefaction plant to be located near the Baltic seaport of Ust-Luga, Leningrad Oblast will utilize natural gas gathered from domestic sources via Russia's Unified Gas Supply System (UGSS). The EPC contract was signed in September 2021 eyeing to start LNG production by 2026.

MHI President & CEO Seiji Izumisawa said, “We are pleased to supply MHI's H-100 driven compressor trains for this prestigious Ust-Luga LNG plant. This project will showcase the benefits of MHI's LNG solution in terms of lower production costs, increased productivity, reduced complexity and lower lifecycle costs, while significantly reducing plant emissions.”

MHI has an extensive record of delivering state-of-the-art turbomachinery to the oil & gas and petrochemical industries and continues to be a major turbomachinery player in the Russian market.

MHI's H-100 is ideally suited to drive the main refrigeration compressors in large scale LNG plants for several reasons, including:

- Higher efficiency in its Heavy-Duty class, which reduces CO2 emissions, compared with the conventional types of Heavy-Duty gas turbine

- The dual shaft design does not require a large external starter / helper motor, thus contributing to a more compact footprint and space savings

- Operational flexibility, including broad variable-speed operation and full pressure re-starting of the refrigeration compressors, thereby eliminating the need to flare refrigerant

- Utilizing Mitsubishi's cutting-edge combustor technology, the H-100 is the industry leader in low nitrogen oxide emissions (single digit parts per million) in full-load operation

These unique features contribute to maximizing overall plant efficiency and LNG production while providing customers with significant reductions in capital & operational expenditures and emissions compared with competing conventional LNG solutions.

In keeping with its mission to Move the World Forward, the MHI Group will continue to integrate and expand its diverse engineered product line up and technology portfolio to meet the world's needs for energy and reduced GHG emissions.

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, logistics & infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on www.spectra.mhi.com.