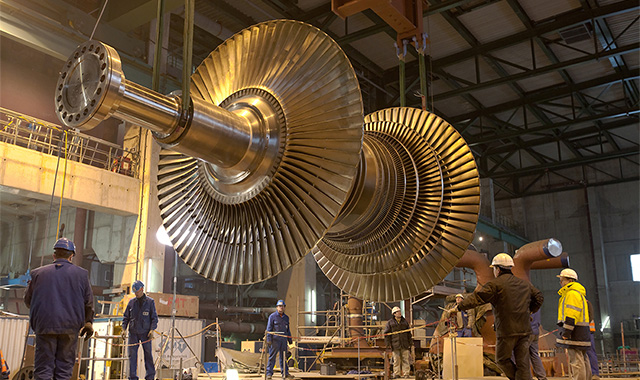

Services

Proposing Service Tailored to Meet Diverse Customer Needs

Mitsubishi Power contributes to availability improvement of the power plant and maximizes asset value of the customer by providing emergency service, preventive maintenance, training, and support for operation and maintenance (O&M) with state-of-the–art ICT technology.

Service Lineup

Service Network

Mitsubishi Power has service locations in different parts of the world and has developed a unique service network called “Diamond Service Network” to realize timely and speedy service for customers around the world.

Our Value for Service

Our after-sales service symbol represents our values.

HSE: HEALTH·SAFETY·ENVIRONMENT

CS: CUSTOMER SATISFACTION

We keep these values “FIRST!” in mind to become a reliable service provider for not only EPC*1 but also after-sales service over a longterm.

Wearing this symbol, we provide service with these values.

- EPC : ENGINEERING · PROCUREMENT · CONSTRUCTION