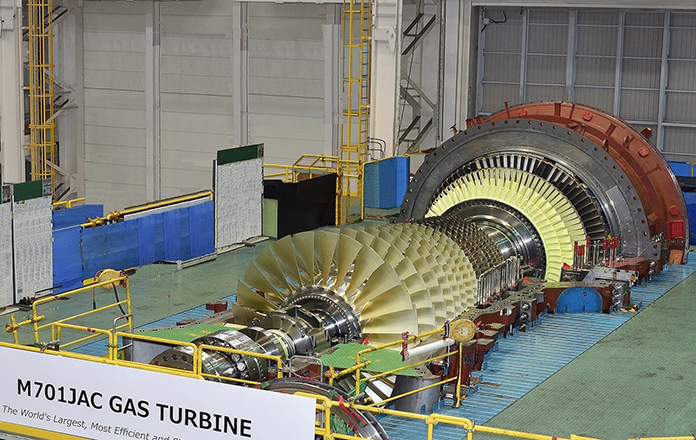

JERA Power Anegasaki Orders Three Cutting-Edge 1,650℃ MHPS M701JAC-type GTCC Power Generating Facilities -- Turnkey Construction Project for New Units 1-3 at the Anegasaki Thermal Power Station in Chiba Prefecture --

・ Total output of 1,950MW, successive start of operations from 2023

・ Project conducted utilizing MHPS’ various resources in Japan

YOKOHAMA, JAPAN (March 18, 2020) – Mitsubishi Hitachi Power Systems, Ltd. (MHPS), has received an order and begun work on a full turnkey contract for construction of new Units 1-3 at the Anegasaki Thermal Power Station (Ichihara City, Chiba Prefecture) operated by JERA Power Anegasaki, part of JERA Co., Ltd. This project will replace the existing power station’s aging gas-fired steam power generation units 1-4 with three 650 megawatt (MW)-class next-generation gas turbine combined cycle (GTCC) generation facilities with cutting-edge 1,650℃ class forced air-cooled M701JAC gas turbines. The upgrade will enhance efficiency to save energy, and reduce the environmental load. The new Units 1-3 are scheduled to begin operations successively from early 2023 through the summer, reaching a total output of 1,950MW.

This project is being conducted as a joint venture between MHPS and Mitsubishi Electric Corporation, which will supply three generators and control systems, under a full turnkey EPC (engineering, procurement, and construction) contract. MHPS will utilize various resources in Japan to supply the equipment; the three gas turbines and related equipment will come from its Takasago Works (Takasago City, Hyogo Prefecture) ; the three steam turbines are sourced from Hitachi Works (Hitachi City, Ibaraki Prefecture), and the heat recovery steam generators and exhaust gas denitrizer systems from its Kure Works (Kure City, Hiroshima Prefecture).

The JAC gas turbines(Note) used for this project are equipped with a forced air-cooled combustor system. Air emitted from the combustor casing is cooled in an external cooler, and the pressure boosted in a forced air-cooled compressor, after which the air is used to cool the combustor, and returned to the casing. This process optimizes the cooling structure. The system also utilizes advanced turbine blade cooling technologies such as an extra thick film thermal insulation coating, and high pressure compressors. This allows for shorter start-up times compared to steam cooling methods, and improves operational efficiency.

MHPS will build on the momentum from this order to focus further on the widespread adoption of next-generation GTCC power plant systems in Japan and around the world, centered on JAC gas turbines and the entire J-Series, as well as contribute to the stable supply of the electric power essential for economic development throughout the world, promote the decarbonization of energy, and support the conservation of the global environment.

- See the following website for information on the advantages of JAC gas turbines:

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, logistics & infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on www.spectra.mhi.com.