Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

Development of the JAC-Series

Design Concept

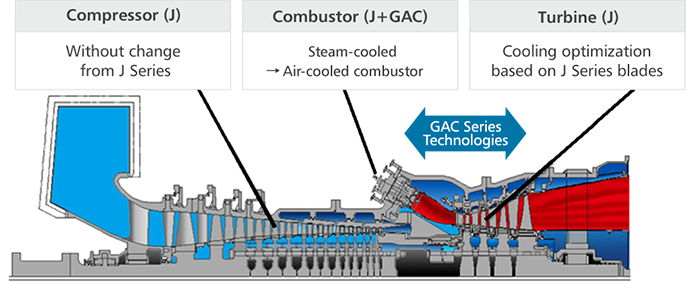

The JAC-Series gas turbines are based on the J-Series that introduces steam cooling to the combustor. Adopting the air cooled combustor used in the GAC Series, it features a shorter startup time and other enhanced operability functions while retaining performance comparable with that of the J-Series.

Features of the Jac-Series

The flow path of the compressor and the turbine has the same shape as that of the J-Series. The JAC-Series has a cooling structure for the blades and vanes of the turbine, optimized according to the air cooled combustor. The combustor adopts the air cooling system, which has a proven track record in the GAS-Series. It also features the low NOx technology verified with the J-Series.

Development of Next-Generation Gas Turbines

Mitsubishi Power has released to the market the J-Series Air Cooled (or JAC-Series) gas turbines as the latest models in the J-Series. As the name suggests, they are air-cooled gas turbines. In combined cycle operation, the JAC-Series achieves power generation efficiency of at least 63%.

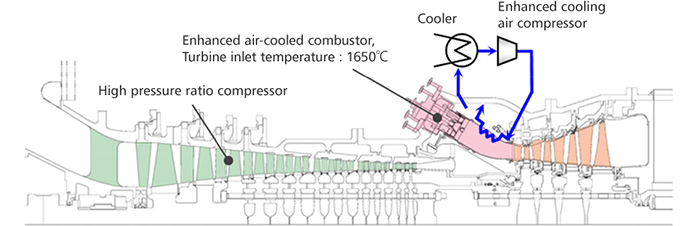

The diagram depicts the schematic of the enhanced air cooling system (Note). The air extracted from the compressor outlet (combustor casing) is cooled with an exterior cooler. Then it is pressurized by the enhanced cooling air compressor to be used for cooling the combustor. Next the air is returned to the casing.

- Joint research with Tohoku Electric Power Co., Inc.

The enhanced air cooling system has the following features. It has been verified with Mitsubishi Power' combined cycle power plant demonstration facility.

- Exhaust heat from the external cooler is recovered in the bottoming cycle for a system that is excellent in efficiency.

- The combustor cooling mechanism is optimized to produce cooling performance equivalent to that of steam cooling.

- This system starts up faster than the steam cooling system.

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report