INSIGHTS

Extending the Life of G-Class Gas Turbines with Strategic Retrofits

Index

The global power sector is undergoing a fundamental transformation. As intermittent renewables like wind and solar grow their share of electricity generation, the demands being placed on gas turbine-based power plants are evolving.

In many regions with high renewable grid penetration, utility-scale plants are no longer required to provide steady baseload power. Their operation is becoming more dynamic – requiring greater turndown, along with faster start-up and load ramping to balance the inherent variability of solar and wind generation and smooth out “duck curves”, which are becoming more pronounced.

Many power plants with gas turbines installed decades ago are not optimized for these new load profiles and will require strategic retrofits to maintain grid reliability.

For operators of Mitsubishi Power’s M501G Series gas turbines, converting from steam- to air-cooled combustors is one of several available upgrades that can improve power plant flexibility, shorten start-up time, and enable efficient operation in power markets where renewable generation is increasing.

Conversion to air-cooled technology also enhances hydrogen co-firing capabilities, creating future opportunities for CO2 emission reductions without requiring power capacity replacements.

Converting from Steam- to Air-Cooled Combustors

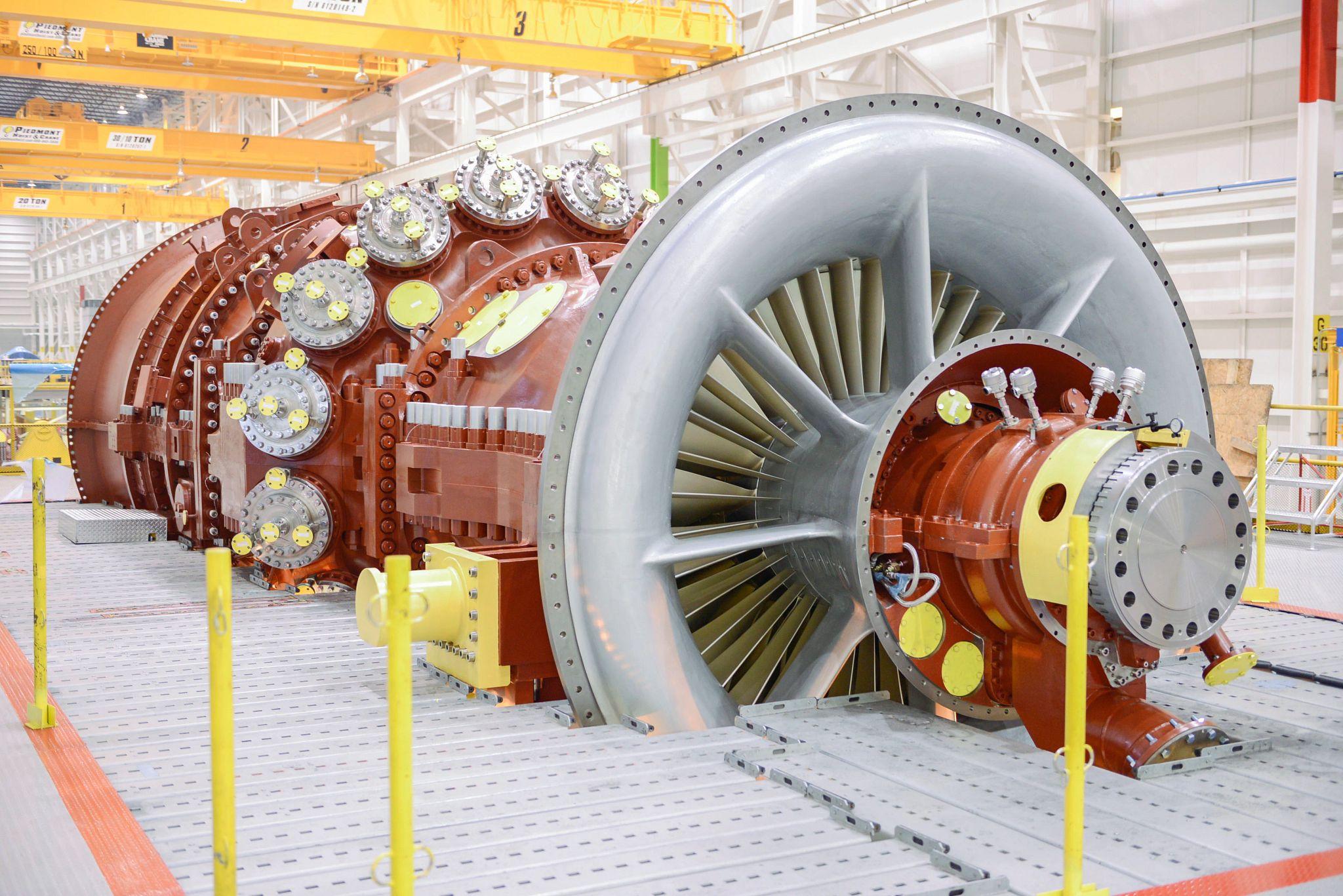

The G Series gas turbine fleet, which uses traditional steam-cooled combustors, has accumulated 7+ million operating hours of reliable performance over 20 years. The M501GAC Series utilizes the same proven technology as the original steam-cooled G Series but incorporates state-of-the-art, air-cooled combustors.

In the M501GAC configuration, compressor discharge air cools the components – eliminating the requirement for steam cooling and removing the gas turbine’s dependency on steam quality from the bottoming cycle. Each combustor uses a fully premixed fuel-injection system that minimizes NOx and CO emissions, providing increased flexibility to meet the demands of modern power grids.

The GAC conversion process can be completed during a normal scheduled plant outage. Primary work scope activities include:

• Installation of the new air-cooled combustor and casing modification

• Modification of the row 1 turbine blade ring

• Removal of the combustor bypass and associated equipment

• Installation of new fuel gas stages

• Removal of cooling steam supply and return piping

• Installation of new instrumentation and control logic

Future-Proofing the McDonough-Atkinson Power Plant in Georgia

Mitsubishi Power recently completed an air-cooled combustor conversion in the United States on two M501G gas turbines at Georgia Power’s McDonough-Atkinson combined cycle plant in Smyrna, Georgia. The primary goal of the project was to shorten the power block’s start-up time by eliminating the need for cooling steam prior to gas turbine operation and the additional time previously required to establish proper steam conditions during the load-up phase.

Increased turndown capabilities by switching to air-cooled combustors also enable the plant to reduce cycling, maintain the necessary spinning reserve to ensure grid reliability, and improve the facility’s service factor in anticipation of higher renewables penetration in the coming years.

The GAC conversion was completed during a planned outage, alongside several performance-enhancing upgrades. These included the implementation of pre-mix pilot technology to improve combustion stability and reduce emissions, the kai turbine upgrade to increase output and improve heat rate efficiency, and a turbine cooling air (TCA) bypass to optimize cooling air usage and further enhance overall turbine performance.

Increased Turndown and Shorter Start-Up Time

The retrofit at the McDonough-Atkinson plant achieved Georgia Power’s objective of shortening start-up duration – reducing the time from unit start to dispatchable, reliable power by 3 hours. In combination with pre-mix fuel injection, cooling flow modulation, and TCA bypass, the upgrades expanded the unit’s turndown range by approximately 20%, improving operational flexibility while maintaining stable and efficient performance at lower loads.

The TCA bleed is a turbine bypass mechanism. By removing air from the combustion process, partial-load firing temperature increases and CO formation decreases. This has enabled the plant to expand its operating range by reducing the minimum environmental compliance load (MECL).

Enhancing Hydrogen Co-Firing Capabilities

In addition to improved turndown and start-up times, conversion to the GAC configuration supports Georgia Power’s long-term goal of decarbonizing power generation through hydrogen co-firing.

In June 2025, Georgia Power and Mitsubishi Power successfully completed a second trial blending hydrogen and natural gas fuels at both partial and full load on one of the plant’s M501GAC gas turbines.

The demonstration project is the first to validate 50%1 hydrogen fuel blending on an advanced-class gas turbine, and the largest test of its kind to date. At 50% hydrogen, CO2 emissions are reduced by approximately 22% compared to 100% natural gas. Several tests were conducted prior to the 50% demonstration, with blends ranging from 5%-50%.

Reducing OPEX and Improving Power Plant Reliability

The upgrades have also contributed to reduced OPEX and higher plant reliability.

The implementation of pre-mix pilot technology resulted in a net reduction in NOx emissions levels to less than 13 ppm. Aside from the environmental benefit, ammonia consumption in the gas turbine’s Selective Catalytic Reduction (SCR) system has decreased, translating to lower costs.

Moreover, by eliminating the need for cooling steam, several maintenance-intensive systems have been removed, including auxiliary boilers and the combustor bypass. Less frequent cycling of the gas turbine (i.e., starts and stops) also reduces stress on critical components, particularly combustor parts. Together, these improvements are expected to reduce material fatigue, minimize repair requirements, and extend intervals between planned maintenance outages.

“As renewable generation expands and AI-driven energy demand reshapes the grid, the need for reliable, flexible power has never been greater. Mitsubishi Power is committed to partnering with our customers to implement strategic solutions that enhance reliability, elevate performance, and prepare these assets for a decarbonized future. The McDonough-Atkinson project exemplifies how Mitsubishi Power works alongside operators to build and shape the future of dependable, sustainable power generation.” - Ron Hofer, Director of Product Line, Power Generation Services

Accelerating the Transition to a Low-Carbon Future

Steam-cooled combustors were developed in the late 1990s to achieve industry-leading combined cycle efficiency. While they continue to perform reliably, new demands on gas turbines for peak performance, faster start-up, increased turndown, and compatibility with hydrogen have made air cooling the preferred technology today.

By upgrading to state-of-the-art air-cooled combustors, G-Series operators can economically extend the life of their power plant. When combined with other strategic retrofits, these gas turbines can be modernized into flexible, load-balancing assets capable of maintaining reliable power generation today, while paving a path to a low-carbon future.

To learn more about the McDonough-Atkinson power plant retrofit project, visit here.

Meet Chaya Springer and Ron Hofer and learn how their teams plan outages, execute complex upgrades, and advance hydrogen blending to keep power systems reliable and ready.