H-25

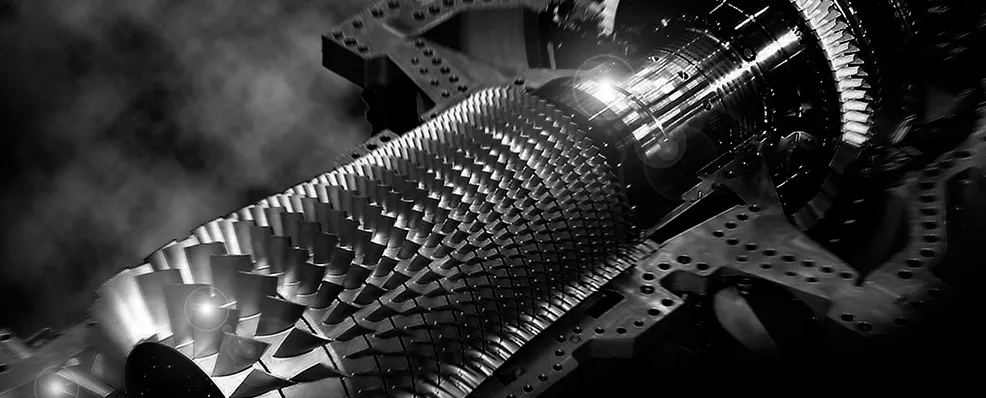

The H-25 Series gas turbines were developed for both utility and industrial customers alike. Our team is committed to continuous improvement and striving for performance enhancements. The H-25 Series provides various options for decarbonization, such as replacing steam power plants with cogeneration plants or utilizing hydrogen. The H-25 will undergo verification for 100% hydrogen firing by 2024 at Takasago Hydrogen Park.

-

Simple Cycle Output

40 MW

-

Combined Cycle Output

60 MW

-

Co-generation Efficiency

Greater than 80%

-

Hydrogen Capable

100%

- Co-generation

- Package Design

- Fuel Flexibility

- Hydrogen Capability

A co-generation plant with the H-25 Series gas turbine produces the highest steam supply volume in the turbine class with high thermal efficiency.

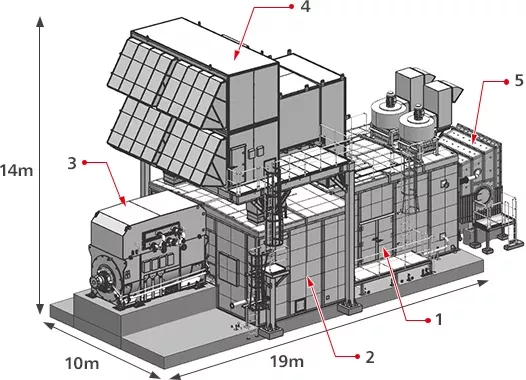

The H-25 and its auxiliaries are designed for a flexible layout, minimizing on-site installation work and time, and easy transportation.

Able to utilize natural gas, off-gas, light oil, kerosene, bio-ethanol, and other fuel types.

H-25 gas turbines use advanced combustion technology, capable of handling a variety of fuels such as off gas. For a future switch from existing fuel gas to hydrogen, the H-25 can accommodate a fuel conversion with minimal modification; only the combustion system needs to be changed.

Resource Link

To accelerate the commercialization of hydrogen, Mitsubishi Power has developed the world’s first center for validation of hydrogen-related solutions, from production to power generation. The Takasago Hydrogen Park currently in operation, will be used to commercialize small and large gas turbines on a path to 100% hydrogen firing starting in 2025.

Enabling Green Hydrogen

Hydrogen is the key to unlocking cleaner power. With the world seeking to reduce emissions from traditional power generation, hydrogen’s role as a clean energy source that does not emit carbon dioxide makes it a viable alternative. And Mitsubishi Power’s large-scale hydrogen-fueled power plants are making carbon-free power generation a reality.

| H-25 | ||

|---|---|---|

| Compressor | Number of Stages | 17 |

| Combustor | Number of Cans | 10 |

| Cooling Method | Air Cooled | |

| Turbine | Number of Stages | 3 |

| Rotor | Number of Rotors | 1 |

| Output Shaft | Cold End | |

| Rated Speed | 7,280 rpm | |

| Gas Turbine | Approx. L × W × H | 7.9 × 3.8 × 3.9m |

| Approx. Weight | 55 ton | |

| Cycle | 50/60 Hz | |

|---|---|---|

| ISO Base Rating | 41.0 MW | |

| Efficiency | 36.2 % LHV | |

| LHV Heat Rate | 9,949 kJ/kWh | |

| 9,432 Btu/kWh | ||

| Exhaust Flow | 114 kg/s | |

| 253 lb/s | ||

| Exhaust Temp | 569 °C | |

| 1,056 °F | ||

| Emission | NOx | 15 ppm@15%O2 |

| CO | 9 ppm@15%O2 | |

| Turn Down Load | 50 % | |

| Ramp Rate | 3.4 MW/min | |

| Starting Time | 22 minutes | |

| H-25 | ||

|---|---|---|

| 1 on 1 | Plant Output | 60.1 MW |

| Plant Efficiency | 54.0% LHV | |

| 2 on 1 | Plant Output | 121.4 MW |

| Plant Efficiency | 54.5% LHV | |

| Starting Time | 55 minutes | |