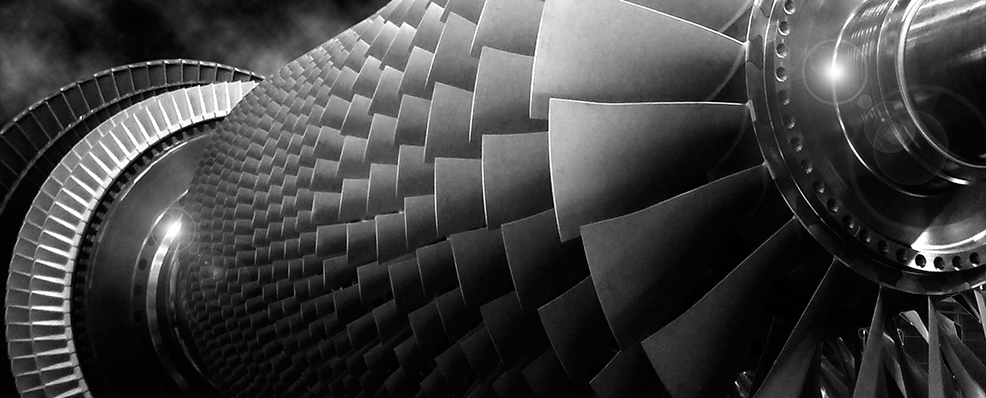

F-Class

Mitsubishi Power developed its F-Class gas turbines in 1991. Since then, the company has been continuously improving the design of its F-Class gas turbines. By incorporating advanced elemental technologies and material technologies verified with the proven track record of the G Series, the F Series has achieved continuous performance enhancement.

-

Simple Cycle Output

180 MW (60 Hz)

380 MW (50 Hz)

-

Combined Cycle Output

280 MW (60 Hz)

570 MW (50 Hz)

-

Fuel Flexibility

Compatible with blast furnace gas (BFG)

- Overall Design

- Compressor

- Combustor

- Turbine

The gas turbine unit is based on a design from the early 1970s that has a proven track record of at least 40 years. Its main features are:

- A compressor shaft end drive reduces the effect of thermal expansion on alignment

- A rotor with simple single-shaft two-bearing support

- A rotor structure has bolt-connected discs with the torque pins in the compressor section and CURVIC couplings in the turbine section to ensure stable torque transmission

- An axial flow exhaust structure advantageous in combined cycle plant layouts

- Horizontally split casings that facilitate field removal of the blades with the rotor in place

Variable inlet guide vanes provide operational stability during start-up and enhanced performance at partial load in combined cycle operation.

A premixing low NOx combustor has one pilot burner and eight main burners surrounding it. The compressor has an air bypass mechanism that regulates the fuel-air ratio in the combustion region.

The first two stages of the turbine have free-standing rotating blades, while the third and fourth stages have integral shroud blades. The stationary vanes are supported by blade rings that are independent at each stage to prevent thermal expansion from affecting the turbine casings.

| M501F | M701F | ||

|---|---|---|---|

| Compressor | Number of Stages | 16 | 17 |

| Combustor | Number of Cans | 16 | 20 |

| Cooling Method | Air Cooled | ||

| Turbine | Number of Stages | 4 | |

| Rotor | Number of Rotors | 1 | |

| Output Shaft | Cold End | ||

| Rated Speed (RPM) | 3,600 | 3,000 | |

| Gas Turbine | Approx. L x W x H (m) | 11.6 x 5.2 x 4.9 | 14.3 x 5.8 x 6.1 |

| Approx. Weight (ton) | 225 | 415 | |

| M501F | M701F | ||

|---|---|---|---|

| Frequency (Hz) | 60 Hz | 50 Hz | |

| ISO Base Rating (MW) | 185.4 MW | 385 | |

| Efficiency (LHV) | 37.0% LHV | 41.9 | |

| LHV Heat Rate | 9,740 kJ/kWh | 8,592 kJ/kWh | |

| 9,230 Btu/kWh | 8,144 Btu/kWh | ||

| Exhaust Flow | 468 kg/s | 748 kg/s | |

| 1,032 lb/s | 1,650 lb/s | ||

| Exhaust Temperature | 613 °C | 630 °C | |

| 1,136 °F | 1,167 °F | ||

| Exhaust Emission NOx | NOx | 25 ppm@15%O2 | 25 ppm @15%O2 |

| CO | 10 ppm@15%O2 | 10 ppm @15%O2 | |

| Turn Down Load | 75 % | 45 % | |

| Ramp Rate (MW/min) | 12 | 38 | |

| Starting Time (minutes) | 30 | ||

| M501F | M701F | ||

|---|---|---|---|

| 1 on 1 | Plant Output (MW) | 285.1 | 498 |

| Plant Efficiency (%LHV) | 57.1 | 59.3 | |

| 2 on 1 | Plant Output (MW) | 57.2 | 999.4 |

| Plant Efficiency (%LHV) |

57.3 | 59.5 | |

| Starting Time (minutes) | 70 | ||