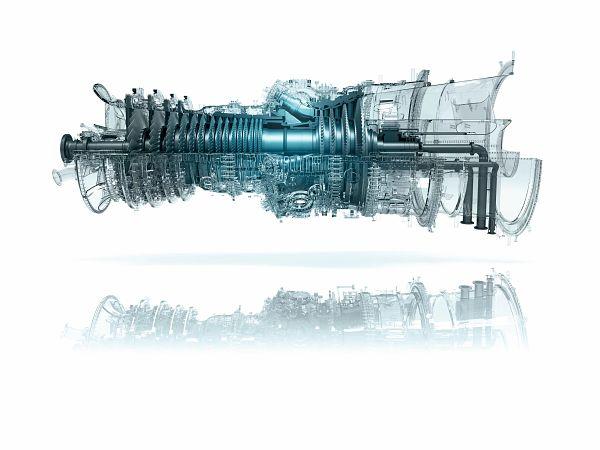

M501J Series

The M501J Series incorporates more than 40 years of gas turbine design, resulting in a high-capacity gas turbine for 60 Hz power generation. With state-of-the-art technologies, they operate at a turbine inlet temperature of 1,600°C.

The M501JAC Series gas turbines adopt air cooling and advanced thermal barrier coating on the turbine blades. This gas turbine provides low levels of NOx, CO2, UHC and VOC emissions. Replacing older coal-fired turbine technology with the new JAC can cut CO2 emissions by nearly 70 percent.

-

Simple Cycle Output

330-453 MW

-

Combined Cycle Output

484-664 MW

-

Combined Cycle Efficiency

Greater than 64%

-

Hydrogen Capable

30% hydrogen co-firing demonstrated at grid-connected T-Point 2

- Output

- Efficiency

- Long-term Validation

- Reliability

- Hydrogen Capability

Industry’s highest rating

J-Class gas turbines offer a higher capacity than any other large-frame gas turbine available in the market, thus maximizing power density in a combined cycle or simple cycle operation.

Mitsubishi Power JAC turbines operating in combined cycle deliver industry-leading efficiency, resulting in a higher reduction in CO2 emissions and improved fuel utilization, which ultimately reduces costs.

T-Point World’s Smartest Power Plant

Mitsubishi Power has a unique design and validation approach, unlike any other Original Equipment Manufacturer (OEM). The current verification process for the J-Class technology takes place at our grid-connected T-Point 2 commercial combined cycle power plant located at Takasago Machinery Works 250-acre campus 30 miles west of Kobe, Japan. In one single location, we house the four key pillars of validation: research and development, design, manufacturing, and full-scale validation. These turbine designs undergo long-term operation of at least 8,000 hours of validation, equivalent to nearly one year of normal operation.

For today’s power producers, disruption is not an option. They need reliable gas turbine systems built on years of innovation and backed by proven technology. Our J-Class gas turbines offer industry-leading reliability; with just 1% higher reliability over 20 years of operation, they can generate more than 1 million additional megawatt-hours while experiencing minimal downtime, resulting in maximum profits.

With over 3.5 million hours of operations on fuels containing hydrogen across 29 units since the 1970s, Mitsubishi Power has established itself as a leader in this technology. Our extensive experience and know-how in handling hydrogen as a fuel give us the confidence to guide you through the transition.

Mitsubishi Power is working tirelessly to develop technology that can transition our JAC Turbines from natural gas to hydrogen. In November 2023, Mitsubishi Power demonstrated the successful operation of a JAC gas turbine using a 30% hydrogen blend. Mitsubishi Power is developing dry low NOx combustion technology for 100% hydrogen firing. The target for completing the rig tests is March 2025, which will be a massive milestone towards achieving the goal of carbon-free gas turbines.

Resource Links

Featured Success Story

Discover how Mitsubishi Power and J-POWER USA worked together to bring the first M501JAC™ units to North America. The plant has powered 1.2 million homes and counting throughout the greater Chicago area and is positioned to support the growth of intermittent renewables and the evolving grid.

Hydrogen-Capable Gas Turbines

Mitsubishi Power's hydrogen firing technology enables power plant owners to decarbonize their existing Gas Turbine Combined Cycle (GTCC) plants by converting them to hydrogen co-firing, or even making them 100% hydrogen firing in the future with minimal modifications.

Product Features

| M501J | M501JAC | ||

|---|---|---|---|

| Compressor | Number of Stages | 15 | |

| Combustor | Number of Cans | 16 | |

| Cooling Method | Steam cooled | Air cooled | |

| Turbine | Number of Stages | 4 | |

| Rotor | Number of Rotors | 1 | |

| Output Shaft | Cold End | ||

| Rated Speed (RPM) | 3,600 | ||

| Gas Turbine Footprint | Approx. L x W x H (m) | 14.4 × 5.4 × 5.7 | 15.0 × 5.6 × 5.6 |

| Approx. Weight (t) | 320 | 347 | |

| M501J | M501JAC | |

|---|---|---|

| Frequency | 60 Hz | 60 Hz |

| ISO Base Rating (MW) | 330 | 453 |

| Efficiency (LHV) | 42.1 % | 44.0 % |

| LHV Heat Rate (kJ/kWh) | 8552 | 8182 |

| LHV Heat Rate (Btu/kWh) | 8,105 | 7755 |

| Exhaust Flow (kg/s) | 620 | 815 |

| Exhaust Flow (lb/s) | 1,367 | 1,685 |

| Exhaust Temperature (°C) | 635 | 649 |

| Exhaust Temperature (°F) | 1,176 | 1,193 |

| Exhaust Emission NOx (ppm@15%O2) | 25 | 25 |

| Exhaust Emission CO (ppm@15%O2) | 9 | 9 |

| Turn Down Load* | 50 % | 50 % |

| Ramp Rate (MW/minute) | 40 | 42 |

| Starting Time (minutes) | 30 | 30 |

* Lower turn down options are available upon request.

| M501J | M501JAC | ||

|---|---|---|---|

| 1 on 1 | Plant Output (MW) | 484 | 664 |

| Plant Efficiency (%LHV) | 62.0 | >64.0 | |

| 2 on 1 | Plant Output (MW) | 971 | 1,332 |

| Plant Efficiency (%LHV) | 62.2 | >64.2 | |