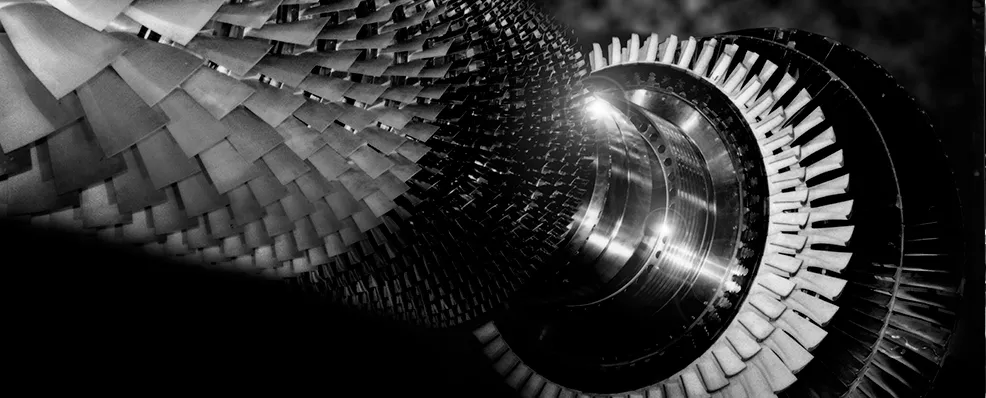

M501G Series

Our M501G Series gas turbines are high-performance large-capacity gas turbines for 60 Hz power generation, featuring the turbine inlet temperature of 1,500°C. The G-Class fleet has accumulated over 7 million actual operating hours of reliable performance for over 20 years.

The GAC Series adopts the latest air-cooled combustors in place of conventional steam-cooled combustors. It uses compressor discharge air for cooling combustors to add operational flexibility by eliminating the need for steam for cooling from the bottoming cycle.

-

Unrivaled Reliability

Over 7 million actual operating hours

-

Simple Cycle Output

270-280 MW

-

Combined Cycle Output

400-430 MW

-

Combined Cycle Efficiency

Greater than 60%

- Enhanced Response Technology Upgrade

- Hydrogen Capable

- Long-term Validation

Mitsubishi Power has developed Enhanced Response technology that leverages data analytics to provide fast start, enhanced ramp rate, and turn down features to enhance the performance of the SmartER M501GAC. This technology is designed to complement intermittent renewables in simple cycle operation. The SmartER M501GAC offers impressive features such as a ten-minute fast start, 50 MW/min ramp rate, low 9 PPM NOx emissions, up to 275 MW output, and advanced class gas turbine efficiency. These features are made possible through the synergy of digital solutions and proven GT frame design.

A commercial power plant, Plant McDonough-Atkinson, successfully demonstrated a 20% hydrogen blend with limited hardware modifications. This showcases the potential for hydrogen retrofitting of the G-Class.

Mitsubishi Power has a unique design and validation approach, unlike any other Original Equipment Manufacturer (OEM). The G-Class technology was validated at the original T-Point facility which began operation in 1997. Located at Takasago Machinery Works 250-acre campus 30 miles west of Kobe, Japan. In one single location, we house the four key pillars of validation: research and development, design, manufacturing, and full-scale validation. These turbine designs undergo long-term operation of at least 8,000 hours of validation, equivalent to nearly one year of normal operation.

Since then, the G-Class fleet has accumulated over 7 million hours with nearly 120 units in operation worldwide.

Located north of Atlanta, the Plant McDonough-Atkinson facility in Smyrna, Georgia, generates enough energy to power more than 1.7 million homes. To bring cleaner, more efficient energy to the area, the plant converted to natural gas in 2012, operating six M501G series gas turbines, along with three steam turbines in a 2-on-1 combined-cycle configuration. Now, as the next step in its decarbonization pathway, Plant McDonough-Atkinson has successfully demonstrated the feasibility of blending 20% hydrogen fuel in its advanced-class gas turbines.

As the demand for electricity grows significantly, Mitsubishi Power provides customized, flexible, and fast-track power generation solutions to help you meet energy needs under the most demanding and adverse conditions. The SmartER M501GAC is designed to complement intermittent renewables in simple cycle operation by providing enhanced performance features such as fast start, enhanced ramp rate, and turn down.

Product Features

| M501G | M501GAC | ||

|---|---|---|---|

| Compressor | Number of Stages | 17 | |

| Combustor | Number of Cans | 16 | |

| Cooling Method | Steam cooled | Air cooled | |

| Turbine | Number of Stages | 4 | |

| Rotor | Number of Rotors | 1 | |

| Output Shaft | Cold End | ||

| Rated Speed (RPM) | 3,600 | ||

| Gas Turbine Footprint | Approx. L x W x H (m) | 12.9 × 5.1 × 5.5 m | 12.9 × 5.1 × 5.5 m |

| Approx. Weight (t) | 295 | 295 | |

| M501G | M501GAC | |

|---|---|---|

| Frequency | 60 Hz | 60 Hz |

| ISO Base Rating (MW) | 267.5 | 283 |

| Efficiency (LHV) | 39.1 % | 40.0 % |

| LHV Heat Rate (kJ/kWh) | 9,211 | 9,000 |

| LHV Heat Rate (Btu/kWh) | 8,730 | 8,531 |

| Exhaust Flow (kg/s) | 612 | 618 |

| Exhaust Flow (lb/s) | 1,349 | 1,364 |

| Exhaust Temperature (°C) | 601 | 617 |

| Exhaust Temperature (°F) | 1,113 | 1,143 |

| Exhaust Emission NOx (ppm@15%O2) | 15 | 15 |

| Exhaust Emission CO (ppm@15%O2) | 9 | 9 |

| Turn Down Load | 50 % | 50 % |

| Ramp Rate (MW/minute) | 18 MW/min | 18 MW/min |

| Starting Time (minutes) | 30 minutes | 30 minutes |

| M501G | M501GAC | ||

|---|---|---|---|

| 1 on 1 | 398.9 MW | 427 MW | 664 |

| 58.4 %LHV | 60.5 %LHV | >64.0 | |

| 2 on 1 | 800.5 MW | 856 MW | 1,332 |

| 58.6 %LHV | 60.7 %LHV | >64.2 | |