INSIGHTS

Pursuing Clean and Reliable Power Generation

The First Cutting-Edge J-Class Gas Turbine in North America

Operating at Power Generation Efficiency of More Than 62%

-

-

The state of Oklahoma is between the Great Plains and the Ozark Plateau in the South Central region of the United States. The state has a diverse and abundant natural environment with more than ten ecological regions. The livestock industry has been thriving in Oklahoma since the territory was first opened to settlers, and the state is known for having the largest cattle auction market in the U.S.

Oklahoma is also the fourth largest crude oil and natural gas producer in the country. The development of Oklahoma City and Tulsa, two large cities in Oklahoma, has been largely fueled by the oil & gas industry.

Just 56 kilometers to the east of Tulsa, Mitsubishi Power delivered an advanced-class gas turbine for a combined cycle (GTCC) power plant to the Grand River Energy Center. The GTCC became the third unit in the Grand River Energy Center run by the Grand River Dam Authority (GRDA), Oklahoma's largest public power company. The center originated with the commissioning of two coal-fired power plants commissioned in the early 1980s, and the GTCC plant was constructed to support the retiring of one coal unit, achievement of emissions reduction and efficiency goals, and to provide a long-term resource for affordable and reliable power to their customers.

-

GRDA selected Mitsubishi Power to supply its highly efficient power generation system to contribute to efficient energy use and environmental load reduction. Our J-class gas turbine at the Grand River Energy Center, which was the first in its class to become operational in North America, achieved the world's highest power generation efficiency for a 60-cycle machine of 62%,exceeding the initially guaranteed performance rate by 2%.(Note)

The system was first fired on March 14, 2017. Just two days after that, it was synchronized to the grid to produce electricity and later conducted a test run of the GTCC plant to accumulate continuous operation hours. All tests were completed 35 days ahead of delivery schedule and the unit was offered into the integrated marketplace as substantially complete in June, 2017.

Currently, the GTCC plant is capable of generating 495 MW of electrical energy and supplies power to 75 of the 77 counties in the state using natural gas produced in Oklahoma as fuel.- World's highest efficiency as of 2017

-

Outcomes

Combined Cycle Power Generation Lowers Carbon Dioxide Emissions by 50%

-

-

Our GTCC system offers the cleanest and most efficient power generation method using fossil fuel. Its power generation efficiency is 62%, which was the highest efficiency in the world when the GRDA plant was commissioned. Compared with conventional coal fired generation, the GTCC system has 20% higher efficiency, and its carbon dioxide emissions are approximately 50% lower.

There are two main methods of thermal power generation. In the steam turbine method, fuel is burned to boil water, which creates steam that turns the turbine to create electricity.

In the gas turbine method, fuel is burned, and the high-pressure combustion gases turn the turbine to create electricity. In both methods, the excess heat created in the steam and gas combustion for turning the turbine is lost as the "waste heat" dissipates into the air.

In GTCC, the high-temperature exhaust gas (at about 600°C) from the gas turbine is collected, and that heat is used to generate the steam used to rotate a steam turbine and generate more electricity using the same amount of heat input or fuel. In other words, it is a hybrid power generation method that combines the gas turbine and steam turbine methods. Since electricity can be produced with less fossil fuel, greenhouse gas emissions such as carbon dioxide can be reduced. Highly efficient and environmentally friendly, the GTCC contributes to the stable supply of electricity and the decarbonization of power generation.

Solutions

25-year, Long-Term Service Agreement

-

The M501J gas turbine used in the third unit of the Grand River Energy Center is the first J-class gas turbine manufactured at the Savannah Machinery Works in the state of Georgia. It is paired in combined cycle with a steam turbine that was built at our Nagasaki Works in Japan. The generators were made by Mitsubishi Electric Company.

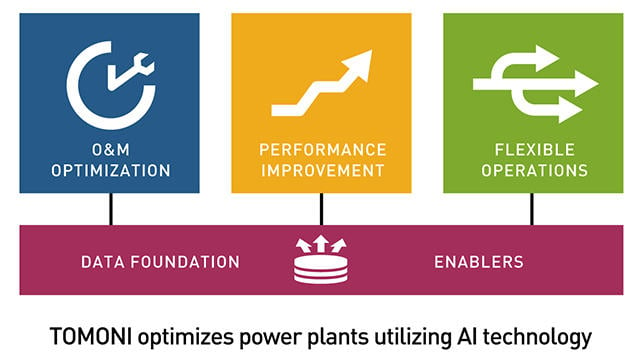

As part of this project, we have signed a 25-year long-term service agreement (LTSA) that includes implementation of TOMONI® intelligent solutions developed by Mitsubishi Power. TOMONI uses artificial intelligence (AI) technology and analyzes equipment operation to optimize plant efficiency and business profitability. This contributes to the reduction of the environmental load. -

Client Testimonial

-

Charles J. Barney, Executive Vice President, Grand River Dam Authority

It has been my privilege to work with the technology team assembled to create Unit 3 at Grand River Energy Center. These partners all shared our vision to set a new standard for efficiency and reliability. Each partner contributed their best engineers and constructors, and I congratulate them on their exceptional accomplishment. This ultra-efficient electric generator is now integrated with our hydro and wind generation, and will help assure that GRDA customers have low-cost, clean and reliable electricity for many decades.