Electrolyzers

Electrolyzers use direct current to split water and potassium hydroxide into hydrogen and oxygen through electrolysis to produce green hydrogen. Water electrolysis involves various technologies such as Proton Exchange Membranes (PEM), Anion Exchange Membranes (AEM), and Solid Oxide Electrolyzer Cells (SOEC).

What is Hydaptive™?

Mitsubishi Power’s standardized designs for hydrogen production, storage, and utilization. A comprehensive suite of solutions for the hydrogen value chain to support the energy transition. Our pre-engineered packages are designed to minimize the time required for front-end engineering reducing cost and commercialization.

With these packages, Mitsubishi Power seamlessly optimizes integration across renewables, energy storage, and gas turbines, which all work together to create and incorporate green hydrogen — the key to reaching zero-carbon emissions.

The green hydrogen energy storage system includes three key elements:

- First, electrolysis plants convert excess renewable energy into hydrogen.

- Next, storage mediums such as salt caverns, pipelines or above ground vessels store this “green hydrogen” for hours to seasons, depending on the grid’s needs.

- Finally, hydrogen-enabled simple cycle or combined cycle gas turbine power plants convert the green hydrogen into centralized dispatchable electricity.

Together, this storage system enables further balancing of renewable energy and better equips states and utilities to reliably and cost effectively meet their climate goals.

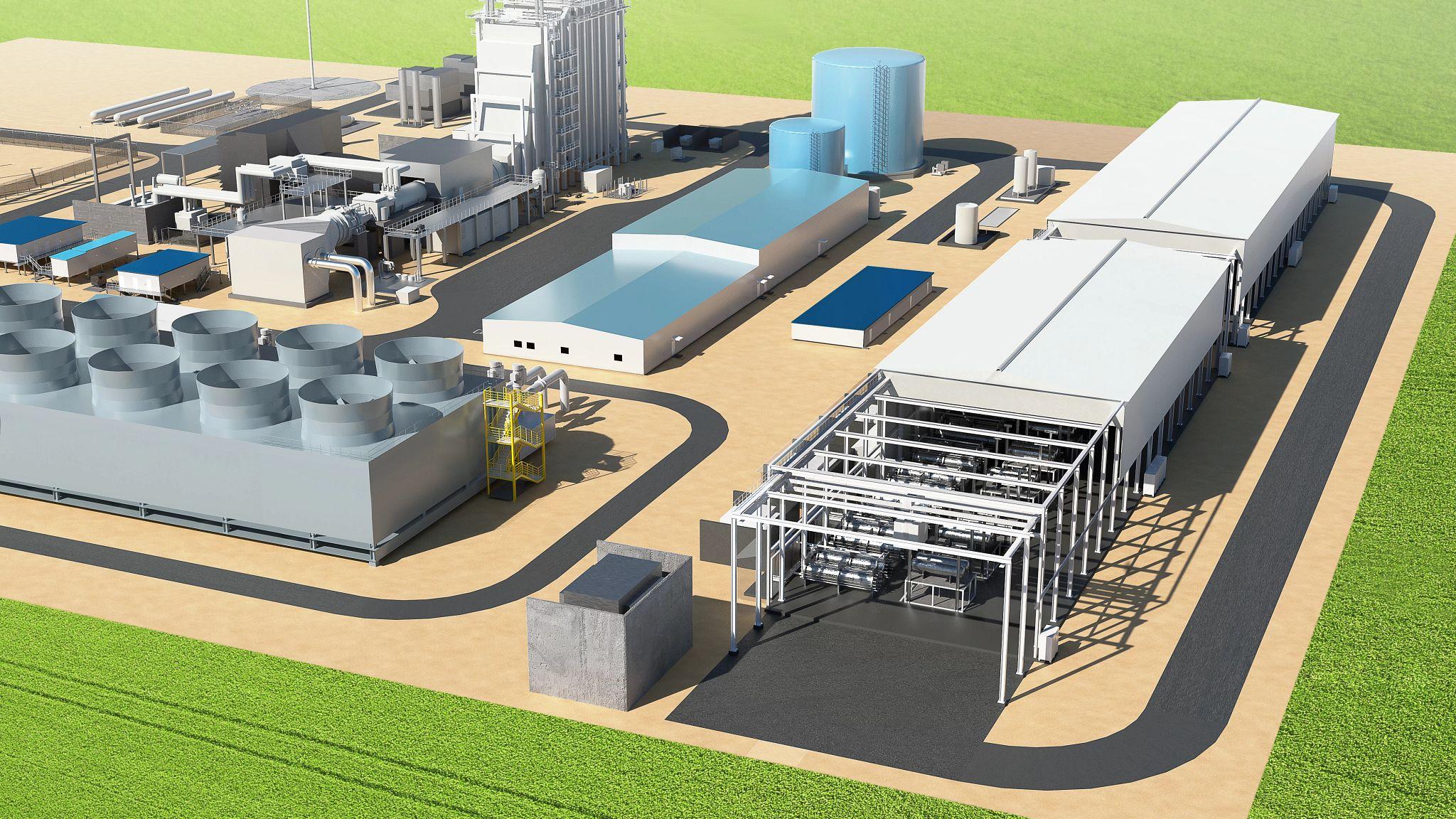

Hydaptive™ Hydrogen Production

A standalone hydrogen facility that offers grid flexibility benefits like demand response, fast start / stop, and optional Volt-Amps Reactive (VAR) support through selected power electronics. Intermittent renewable energy sources can be optimally utilized to capture excess electricity generation.

- Offered in two sizes: Hydaptive™ 110 and Hydaptive™ 220

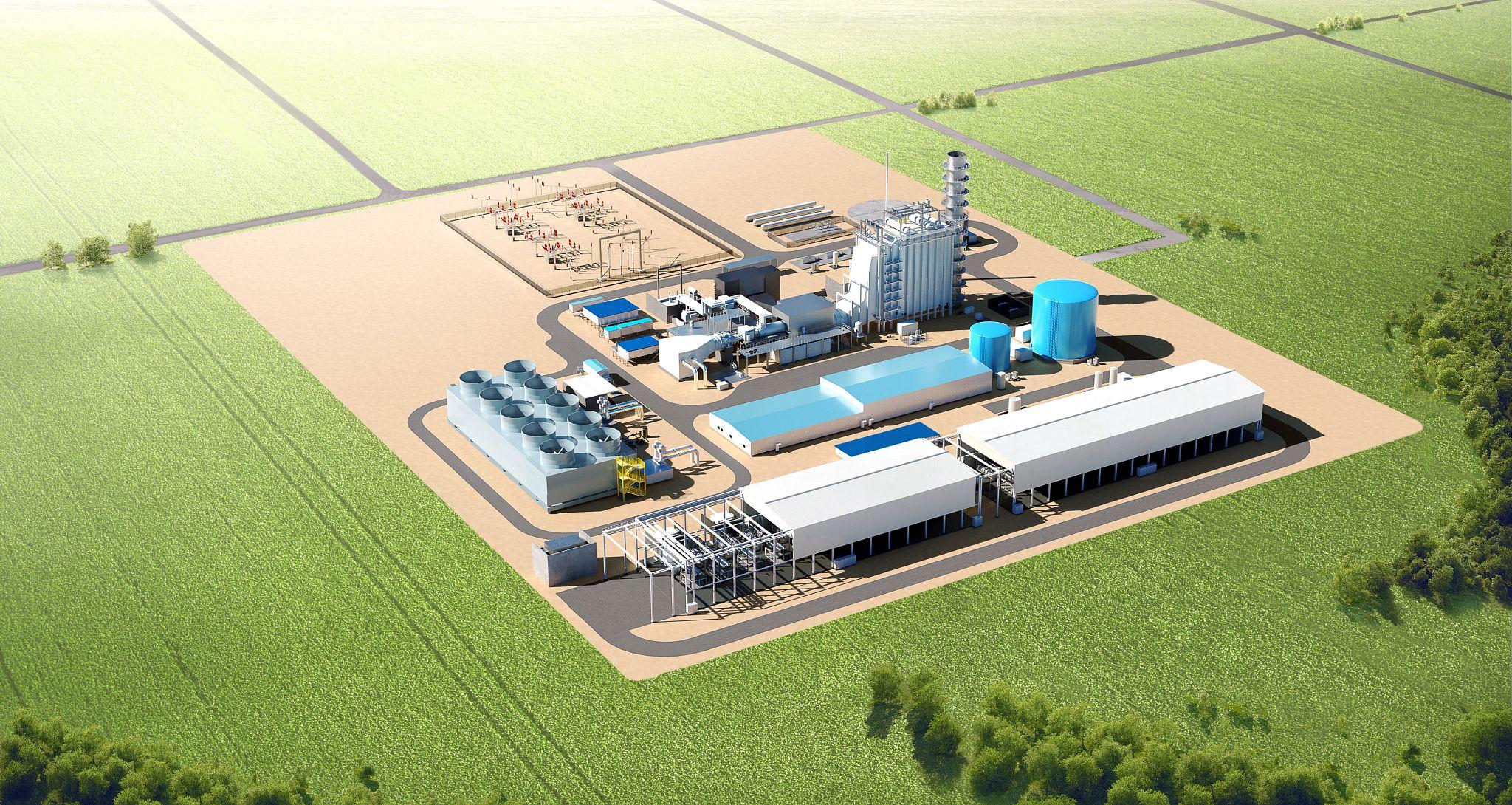

Hydaptive™ Integrated Plant

An all-in-one plant with hydrogen-capable power generation combined with a hydrogen production and storage facility. When the supply of wind and/or solar electricity on the grid, combined with the output of a Mitsubishi Power gas turbine, exceeds demand, the Hydaptive™ controls package will direct the wind and/or solar electricity to an electrolyzer, which creates hydrogen.

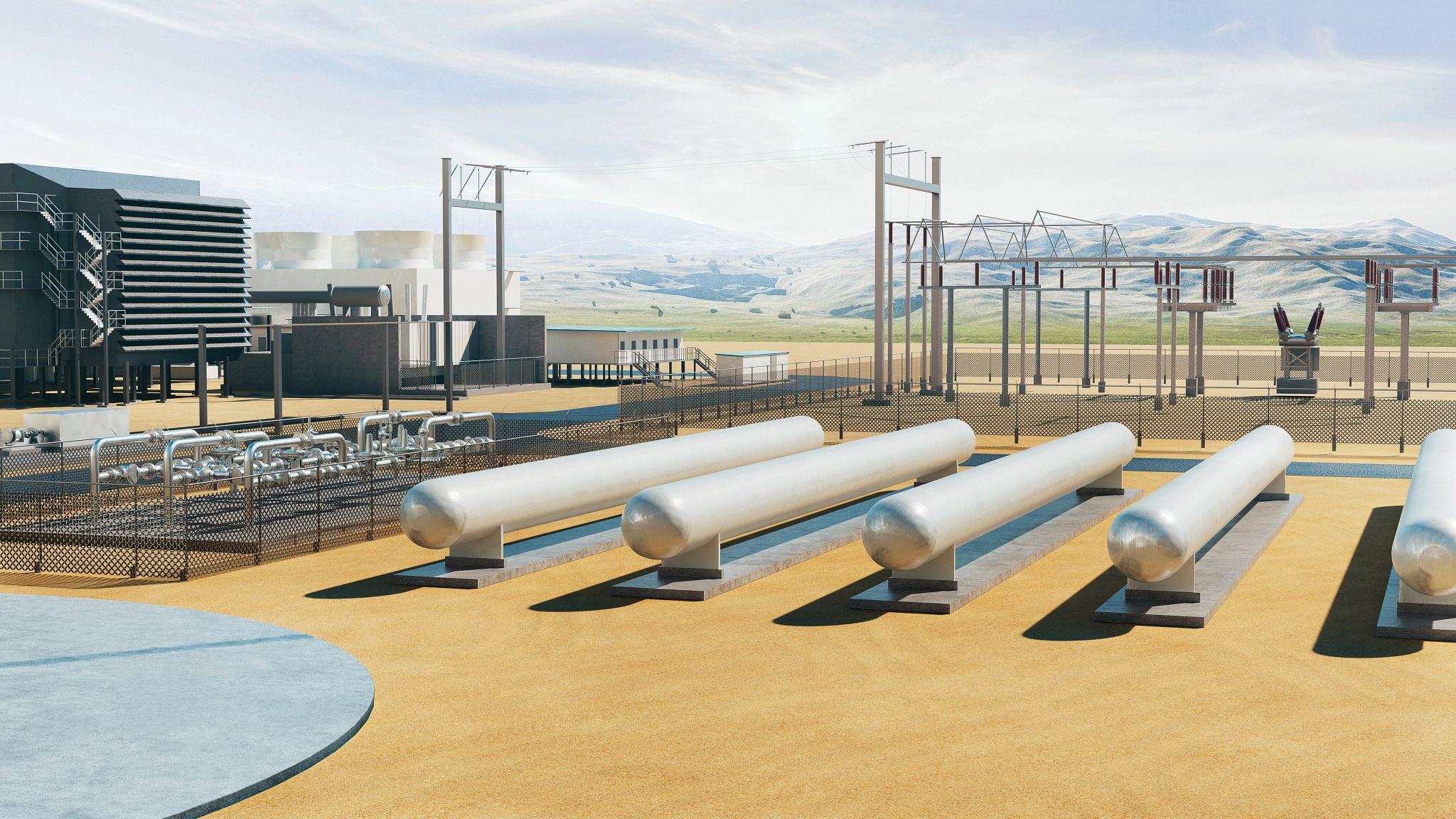

Hydaptive™ Storage

Hydaptive™ Storage package enables large-scale renewable energy storage that shifts variable renewable energy over time, from hours to seasons, in order to provide reliable and cost effective carbon-free energy when the grid needs it most.

Depending on geological and geographical considerations, the Hydaptive™ Storage package can include a combination of pressure vessels and tanks, creating tens of thousands of MW hours of energy in the form of hydrogen, or it can be stored to storage in geological structures such as salt caverns which can create hundreds of thousands of MW hours of hydrogen that can be stored – all nearly indefinitely.

The First Green Hydrogen Standard Packages

Our integrated Hydaptive™ technologies will empower you to produce cost effective hydrogen at scale, and facilitate the transition to a cleaner, more sustainable energy future. Our packages cut through the complexity power generators and grid operators encounter when integrating renewable power, gas turbines, green hydrogen and other energy storage technologies.

- Overview

- Hydrogen Production

- Additional Details

Hardware

| Solution Package | Hydaptive™ Production 110 | Hydaptive™ Production 220 | |

|---|---|---|---|

| Electrolyzer Technology | Pressurized Alkaline Electrolysis (AEL) | ||

| Hardware | |||

| Equipment Scope | AEL Electrolyzer Stacks @5.5 MW | 20 | 40 |

| Gas Separator Skids | 10 | 20 | |

| Transformers (34.5 kV) | 5 | 10 | |

| Rectifiers | 10 | 20 | |

| Balance of Stack | Interconnect piping and control system | ||

| Documentation | General Arrangement, One-Line Diagram, Mass & Heat Diagrams, Process Flow Diagrams, P&IDs, specifications for cooling system, raw water system, demineralized water system, N2 purge, weights & dimensions, equipment list, I/O list, utility summary | ||

| Solution Package | Hydaptive™ Production 110 | Hydaptive™ Production 220 | |

|---|---|---|---|

| Electrolyzer Technology | Pressurized Alkaline Electrolysis (AEL) | ||

| Hydrogen Production per Solution Package | |||

| Production –Hydrogen1 | kg/h | 1889 | 3778 |

| Nm3/h | 21000 | 42000 | |

| Production – Oxygen | kg/h | 7350 | 14700 |

| Nm3/h | 10500 | 21000 | |

| Temperature | 50° C | ||

| Pressure | 15 Barg | ||

| Power (DC) | 110 MW | 220 MW | |

| Efficiency/stack (DC) | 57.25 Kwh/kg | ||

| Purity - Hydrogen | 99.6 mol%, 99.999% with additional purification | ||

| Impurities in Hydrogen (ASTM D 1945) | O2 0.2 – 0.4 mol% balance: N2 <0.1mol%. All others undetectable. | ||

| Electrolyte | 30% KOH | ||

| Operating Range | 50 – 100% | ||

| Demineralized Water at 100% Output | 22,712 kg/h | 45,424 kg/h | |

| Demineralized Water Quality | pH | pH 7-8.5 | |

| Conductivity | <2 μS/cm | ||

Electrolyzer Stack Life

| Solution Package | Hydaptive™ Production 110 | HydaptiveTM Production 220 |

|---|---|---|

| Electrolyzer Technology | Pressurized Alkaline Electrolysis (AEL) | |

| Electrolyzer Stack Life | ||

| Life (between rebuilds) | 10-12 years | |

| Degradation | < 1%/year | |

Size and Certifications

| Solution Package | HydaptiveTM Production 110 | Hydaptive™ Production 220 |

|---|---|---|

| Electrolyzer Technology | Pressurized Alkaline Electrolysis (AEL) | |

| Solution Package Size | ||

| Approximate Footprint | 38,250 m2 | 76,500 m2 |

| Codes & Standards | ||

| Pressure | ASME, PED (European Pressure Directive) | |

| Electrical | UL, IEEE | |

Hydrogen Infrastructure Progressing on Two Fronts

Advanced Clean Energy Storage Project

Learn about the power of collaboration and get a closer look at how we’re building the hydrogen infrastructure of tomorrow through our work at the Advanced Clean Energy Storage project. Located in Delta, Utah, ACES Delta will be a large renewable energy storage facility capable of decarbonizing the western United States and supporting the seamless integration of hydrogen into existing energy systems.

Accelerating Decarbonization: Takasago Hydrogen Park

To accelerate the commercialization of hydrogen, Mitsubishi Power has developed the world’s first center for validation of hydrogen-related solutions, from production to power generation. The Takasago Hydrogen Park will commence operations in 2023 and will be used to commercialize small and large gas turbines on a path to 100% hydrogen firing starting in 2025.