Advancing Hydrogen Blending at Plant McDonough‑Atkinson

Located less than 15 miles from downtown Atlanta, Plant McDonough‑Atkinson has served electric customers for more than 80 years and was fully converted to natural gas in 2012, with capacity to power up to 1.7 million homes. Today, the site stands at the center of a long‑standing partnership between Mitsubishi Power and Georgia Power focused on advancing reliable, lower‑carbon energy.

Together, Mitsubishi Power and Georgia Power have progressively validated hydrogen co‑firing on advanced‑class gas turbines, culminating in the successful demonstration of a 50% hydrogen blend. The McDonough plant proves that meaningful emissions reductions can be achieved today using existing power infrastructure, while setting a global benchmark for scalable hydrogen innovation and the future of flexible power generation.

Supporting Georgia Power's Full Life Cycle Needs

2022: 20% Hydrogen Blending

In 2022, Georgia Power and Mitsubishi Power successfully demonstrated a 20% hydrogen‑natural gas blend on an advanced‑class gas turbine, marking the first validation of its kind in the world.

2024: G to GAC Conversion

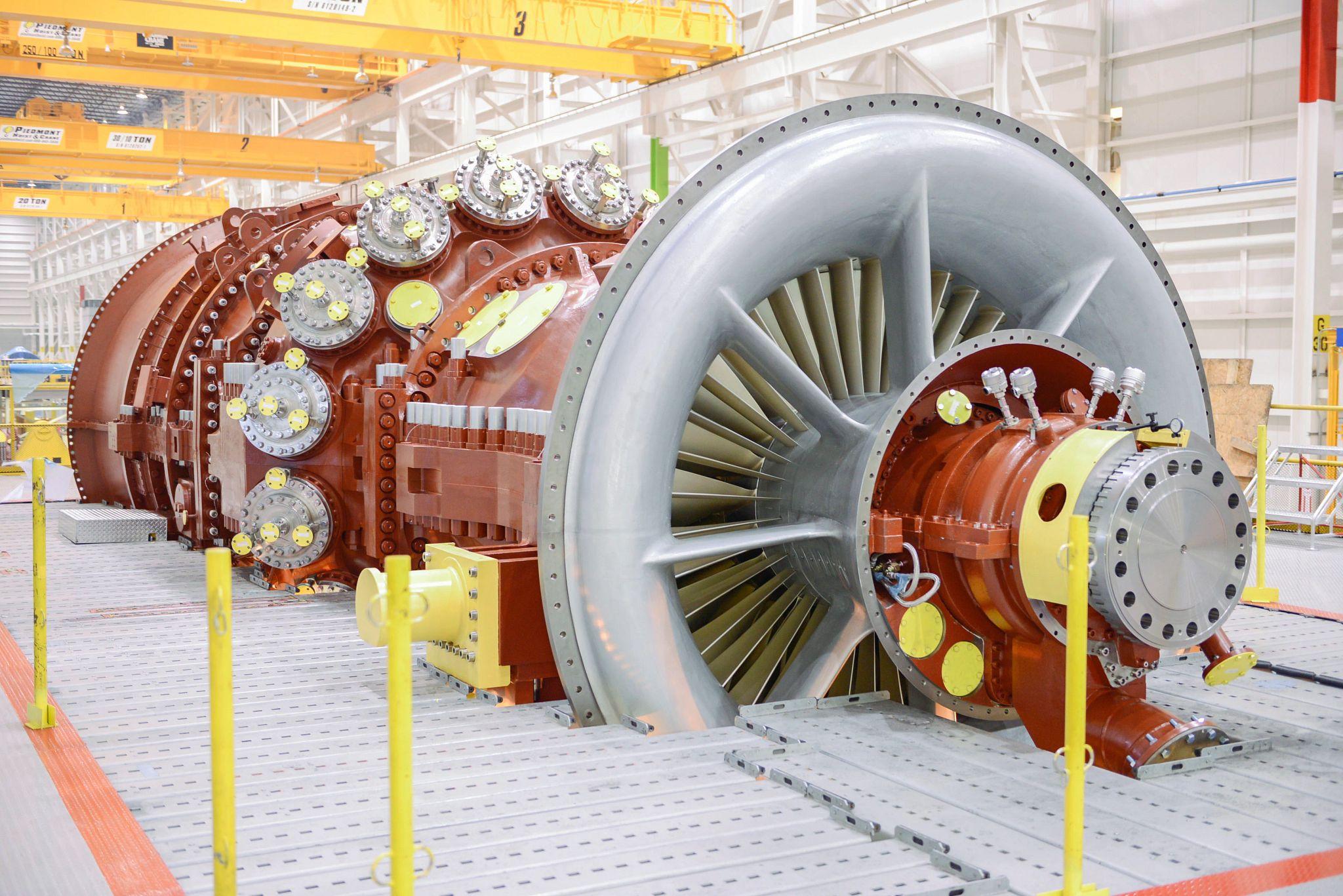

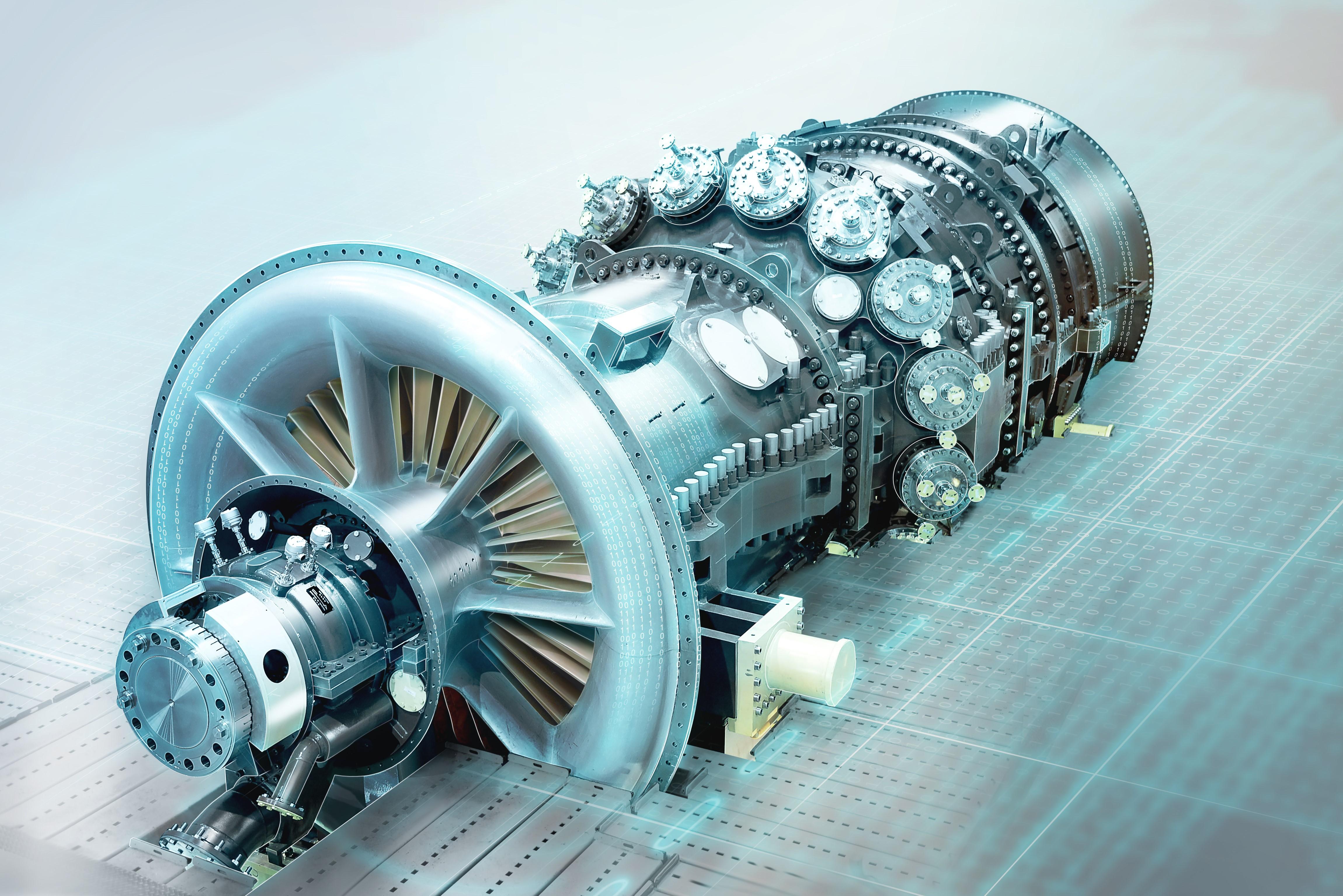

In 2024, Mitsubishi Power upgraded two M501G gas turbines at Plant McDonough‑Atkinson to the advanced M501GAC configuration, converting the units from steam‑cooled to air‑cooled combustion technology.

2025: 50% Hydrogen Blending

In 2025, Georgia Power and Mitsubishi Power successfully validated a 50% hydrogen‑natural gas blend on an advanced‑class M501GAC gas turbine, marking the largest hydrogen blending demonstration of its kind in the world.

A Long Standing Partnership

"Our partnership made this project possible. By relying on each other and working toward a shared goal, we were able to push the boundaries of technology and innovation. It didn’t matter which hard hat we wore, we operated as one team."

Latonya Johnson, Plant Manager at Plant McDonough Atkinson

2025: World‑Leading 50% Hydrogen Blending Demonstration

In 2025, Georgia Power and Mitsubishi Power successfully completed a landmark 50% hydrogen blending test at Plant McDonough‑Atkinson, marking the highest hydrogen blend ever validated on an advanced‑class gas turbine. Conducted on a M501GAC gas turbine, the demonstration confirmed that hydrogen and natural gas can be co‑fired at utility scale under both partial and full load conditions using existing power infrastructure.

Demonstration Highlights

• Demonstrated 50% hydrogen blending on an advanced‑class gas turbine

• Validated operation across partial and full load

• Largest hydrogen blending demonstration of its kind conducted to date

• Achieved an estimated 22% reduction in CO₂ emissions compared to 100% natural gas

2024: Modernizing the Fleet Through G to GAC Conversion

A Retrofit Built For Evolving Grid Needs

In 2024, Mitsubishi Power upgraded two M501G gas turbines at Plant McDonough‑Atkinson to the advanced M501GAC configuration, replacing steam‑cooled combustors with air‑cooled combustion technology. This conversion was a critical step in preparing the plant for a more dynamic grid and enabling higher levels of hydrogen co‑firing.

Key outcomes of the G‑to‑GAC upgrade included:

• Faster start‑up times

• Expanded turndown capability

• Greater operational flexibility

• Enhanced hydrogen co‑firing capability,

• Extended asset life and long‑term value using existing infrastructure

Meet the Team Behind the McDonough Project

In this video, two of the leaders behind the McDonough milestones, Chaya Springer and Ron Hofer, take viewers inside the teams and decisions that made world‑leading hydrogen blending possible.

Their perspective highlights how disciplined planning, cross‑functional alignment, and strong leadership across engineering, supply chain, and field teams helped modernize existing assets and deliver real‑world impact at utility scale.

2022: North America’s first validated 20% hydrogen blend on an advanced‑class turbine

In June 2022, Georgia Power, Mitsubishi Power, Southern Company Research & Development, and EPRI completed North America’s first validated 20% hydrogen blend on an advanced‑class gas turbine. The demonstration achieved a 20.9% blend, resulting in meaningful emissions reduction while maintaining strong performance and reliability under real‑world operating conditions.