M501F Series

-

Standalone Gas Turbine Output

180 MW class

-

Combined Cycle Output

280 MW class / 580 MW class

-

Fuel Diversification

Compatible with blast furnace gas (BFG)

Gas turbines for 60 Hz power generation matched with diversification of fuels

In 1991, Mitsubishi Power developed the M501F Series gas turbines for 60 Hz power generation. The following year, it developed the M701F Series for 50 Hz power generation as a series with similar design.

Since then, Mitsubishi Power has continued to improve the design of F Series gas turbines. While introducing advanced elemental technologies and material technologies verified with the G Series with a proven track record, the F Series attains continuous performance enhancement.

Overall Design

The gas turbine unit is based on the basic structure adopted in the early 1970s that has accumulated a track record of at least 40 years. Its main features are as follows:

- A compressor shaft end drive reduces the effect of thermal expansion on alignment

- A rotor with simple single-shaft two-bearing support

- A rotor structure has bolt-connected discs with the torque pins in the compressor section and CURVIC couplings in the turbine section to ensure stable torque transmission

- An axial flow exhaust structure advantageous in combined cycle plant layouts

- Horizontally split casings that facilitate field removal of the blades with the rotor in place

Compressor

Variable inlet guide vanes ensure operational stability at the start-up and enhanced performance at partial load in combined cycle operation.

Combustor

A premixing low NOx combustor is composed of one pilot burner and eight main burners that surround it. The compressor has an air bypass mechanism that enables fuel-air ratio regulation in the combustion region.

Turbine

Rotating blades at the first two stages are free-standing, while those at the third and fourth stages are integral shroud blades.

Stationary vanes are supported by blade rings that are independent at individual stages to prevent turbine casings from being affected by thermal expansion.

Configuration

| M501F | ||

|---|---|---|

| Compressor | Number of Stages | 16 |

| Combustor | Number of Cans | 16 |

| Cooling Method | Air Cooled | |

| Turbine | Number of Stages | 4 |

| Rotor | Number of Rotors | 1 |

| Output Shaft | Cold End | |

| Rated Speed | 3,600 rpm | |

| Gas Turbine | Approx. L × W × H | 11.6 × 5.2 × 4.9 m |

| Approx. Weight | 225 ton | |

Simple Cycle Performance

| M501F | ||

|---|---|---|

| Frequency | 60 Hz | |

| ISO Base Rating | 185.4 MW | |

| Efficiency | 37.0 %LHV | |

| LHV Heat Rate | 9,740 kJ/kWh | |

| 9,230 Btu/kWh | ||

| Exhaust Flow | 468 kg/s | |

| 1,032 lb/s | ||

| Exhaust Temperature | 613 °C | |

| 1,136 °F | ||

| Exhaust Emission | NOx | 25 ppm@15%O2 |

| CO | 10 ppm@15%O2 | |

| Turn Down Load | 75 % | |

| Ramp Rate | 12 MW/min | |

| Starting Time | 30 minutes | |

Combined Cycle Performance

| M501F | ||

|---|---|---|

| 1 on 1 | Plant Output | 285.1 MW |

| Plant Efficiency | 57.1 %LHV | |

| 2 on 1 | Plant Output | 572.2 MW |

| Plant Efficiency | 57.3 %LHV | |

| Starting Time | 70 minutes | |

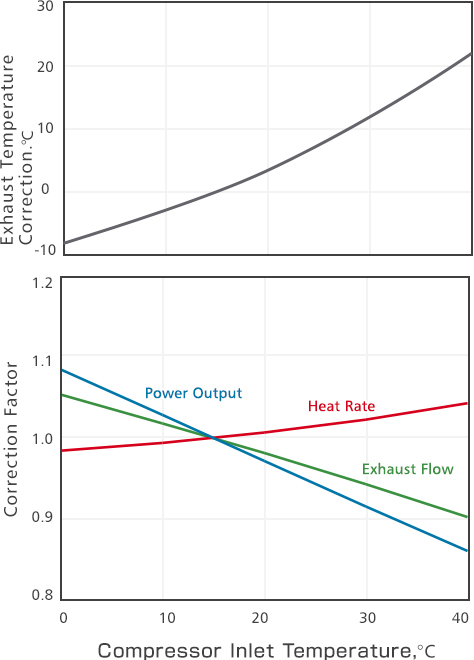

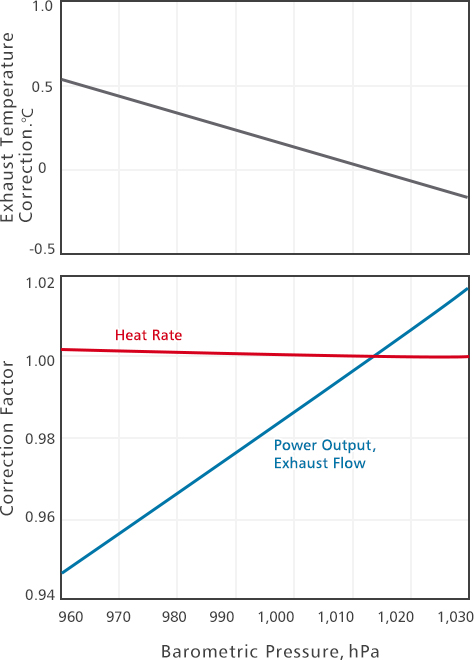

Performance Correction Curves

-

Effects of Compressor Inlet Temperature on Gas Turbine Performance (Typical)

-

Effects of Barometric Pressure on Gas Turbine Performance (Typical)

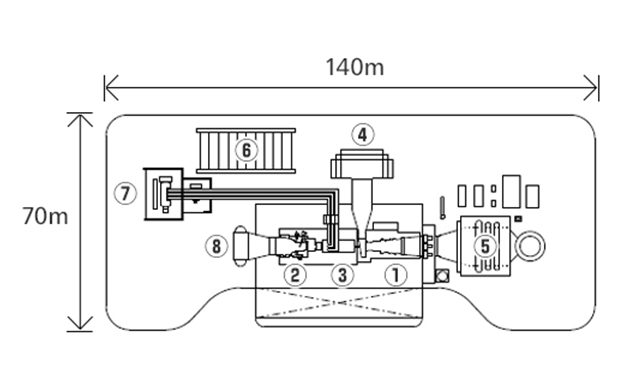

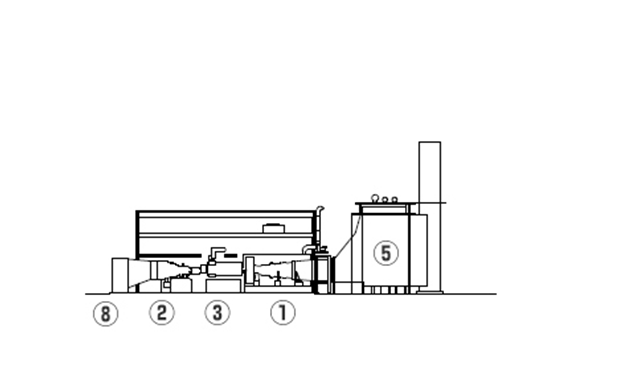

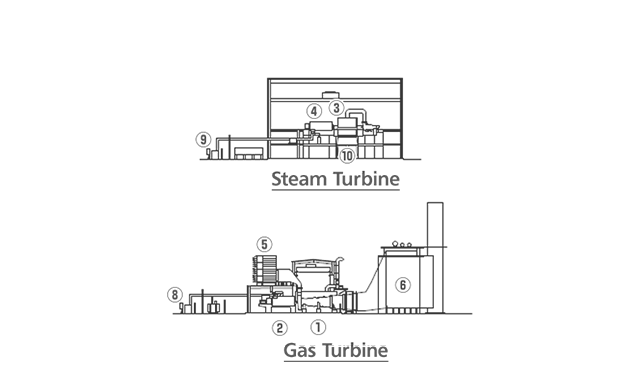

Typical Plant Layout - 1 on 1 configuration, single-shaft

- Gas Turbines

- Steam Turbines

- Generators

- Inlet Air Filter

- Heat Recovery Steam Generator (HRSG)

- Electrical / Control Package

- Main Transformer

- Condenser

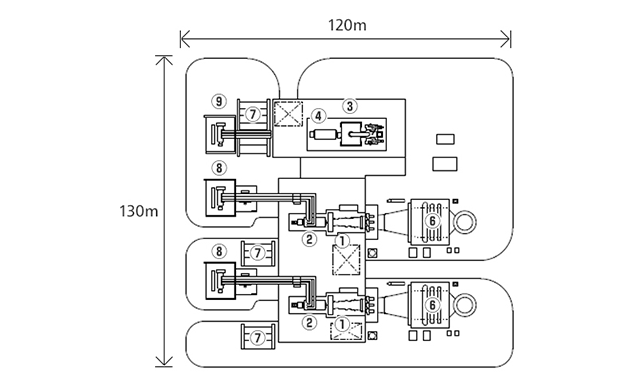

Typical Plant Layout - 2 on 1 configuration

- Gas Turbines

- GT Generator

- Steam Turbines

- ST Generator

- Inlet Air Filter

- Heat Recovery Steam Generator (HRSG)

- Electrical / Control Package

- GT Main Transformer

- ST Main Transformer

- Condenser

Main Delivery Records

Himeji No. 1 Power Station Unit 5, The Kansai Electric Power Co., Inc. (Japan) (Photo courtesy of The Kansai Electric Power Co, Inc.)

729 MW, 3 x M501F

Kawagoe Thermal Power Station Group 4, Chubu Electric Power Co., Inc. (Japan)

1,701 MW, 7 x M501F

Mizushima Power Station Unit 1, The Chugoku Electric Power Co., Inc. (Japan)

285 MW, 1 x M501F

Sakaide Thermal Power Station Unit 1, Shikoku Electric Power Co., Inc. (Japan)

283.1 MW, 1 x M501F

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Others

- Catalogue

- HIACS Series

- Technical Report