Drum Boilers

Overview

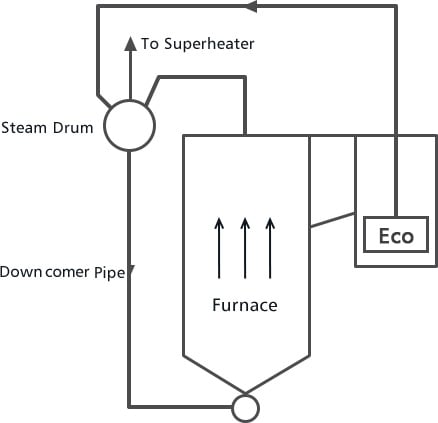

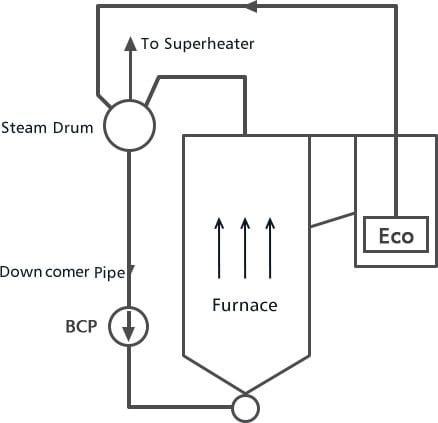

In a drum boiler, the circulation of water is produced through the density difference of water in the down comer pipe and the water/steam mixture in the furnace tubes. In low-pressure boilers where this density difference is large, the circulating force is high and a high volume of circulation can be ensured, but since it becomes difficult to maintain sufficient circulation volume when the density difference between the two drops due to higher pressure, a pump (BCP) is installed in the down comer pipe to supplement circulating force. The type that circulates water using only the density difference is called a natural circulation boiler, while the type that includes a pump is called a forced circulation boiler.

Natural Circulation Boiler Fluid Path Diagram

Forced Circulation Boiler Fluid Path Diagram

Delivery Records

-

Forced Circulation Boiler

Customer BLCP Plant (Country) BLCP Power Station (Thailand) Output 717 MW Maximum continuous rating 2,285t/h Steam conditions Main steam temperature 538°C Reheat steam temperature 538°C Main steam pressure 16.7 MPaA Fuel Bituminous coal Start of operation 2006 -

Natural Circulation Boiler

Customer Cairo Electricity Production Company Plant (Country) Cairo West Power Station Units 7 and 8 (Egypt) Output 350 MW Maximum continuous rating 1,094t/h Steam conditions Main steam temperature 541°C Reheat steam temperature 541°C Main steam pressure 18.1 MPaA Fuel Natural gas, heavy oil Start of operation 2011

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report