Heat Recovery Steam Generators (HRSG)

Overview

A heat recovery steam generator (HRSG) is one of the major pieces of equipment in a gas turbine combined cycle power plant that boasts a high thermal efficiency and produces minimal CO2 emissions. An HRSG is a kind of heat exchanger that recovers heat from the exhaust gases of a gas turbine to an extreme degree. The heat is recovered in the form of steam which is served as the power source of a power-generating steam turbine.

For the heat-transfer tubes of an HRSG, finned tubes with excellent heat-transfer performance are employed. By adopting a compact design, the installation footprint of the equipment is reduced.

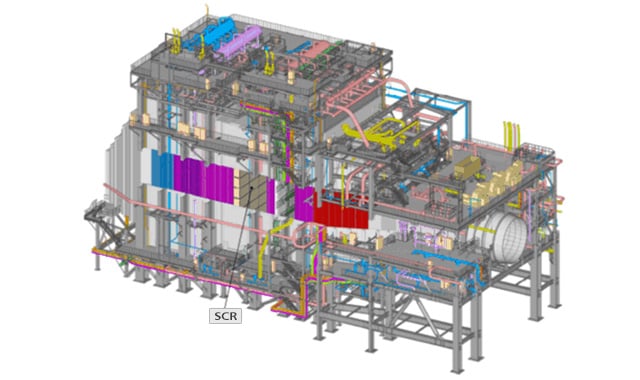

In addition, Selective Catalyst Reduction (SCR) equipment is installed inside the HRSG, reducing the content of nitrogen oxides in the exhaust gases released into the atmosphere.

Bird's-eye View of HRSG

Features

High Performance and High Reliability

Since Mitsubishi Power delivered its first HRSG in 1963, it has pursued the optimization of its HRSG offerings based on an extensive delivery track record and operational experience.

Mitsubishi Power has manufactured and delivered HRSG with high reliability to accommodate the demand for higher gas turbine capacities as well as for higher temperatures and pressures in steam, associated with the higher efficiency and output of power plants.

Highly economical

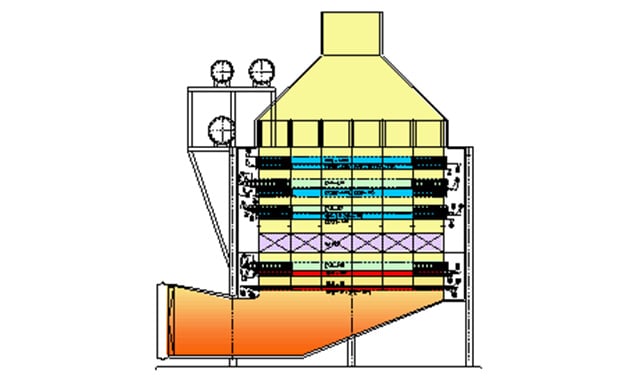

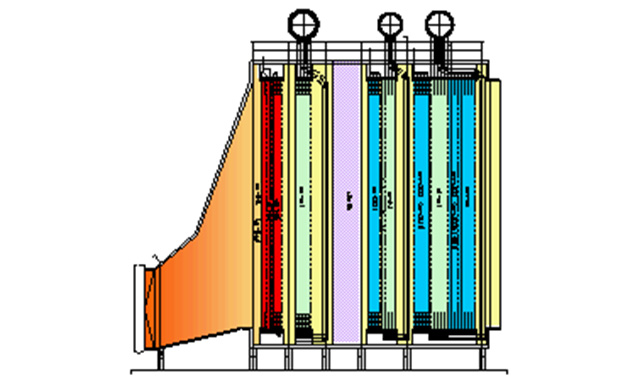

Mitsubishi Power offers two types of HRSG, a vertical gas flow type (Vertical HRSG) and a horizontal gas flow type (Horizontal HRSG). In addition, by combining a vast array of established construction methods for assembly and installation, Mitsubishi Power can develop proposals with specifications optimized to the transportation and site requirements.

HRSG Types

Vertical HRSG

Horizontal HRSG

Construction Methods for Assembly and Installation (examples for horizontal HRSG)

Harp Construction Method

Block Construction Method

Modular Construction Method

Delivery Records

-

Triple Pressure Natural Circulation Type (Horizontal Gas Flow Type)

Customer JERA Co.,Inc. Plant (Country) Kawasaki Thermal Power Station Units 2-2 and 2-3 (Japan) Steam rate 480 t/h (HP)

140 t/h (IP)

100 t/h (LP)Steam conditions HP Superheater outlet 602°C/15.4 MPa Reheater outlet 602°C LP Superheater outlet 252°C Start of operation 2016 -

Triple Pressure Natural Circulation Type (Horizontal Gas Flow Type)

Customer Okinawa Electric Power Company Plant (Country) Yoshinoura Power Plant Units 1 and 2 (Japan) Steam rate 203 t/h (HP)

37 t/h (IP)

33 t/h (LP)Steam conditions HP Superheater outlet 550°C/11.0 MPa Reheater outlet 550°C LP Superheater outlet 232°C Start of operation 2012 / 2013

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report