FT4000® SWIFTPAC®

-

Gas-turbine single-body efficiency

>41% simple-cycle efficiency

-

Most powerful aero-derivative package available in its class (SWIFTPAC® 140)

140 MW

-

Significant commonality with aero engine

High reliability

FT4000® SWIFTPAC® Gas Turbine Package

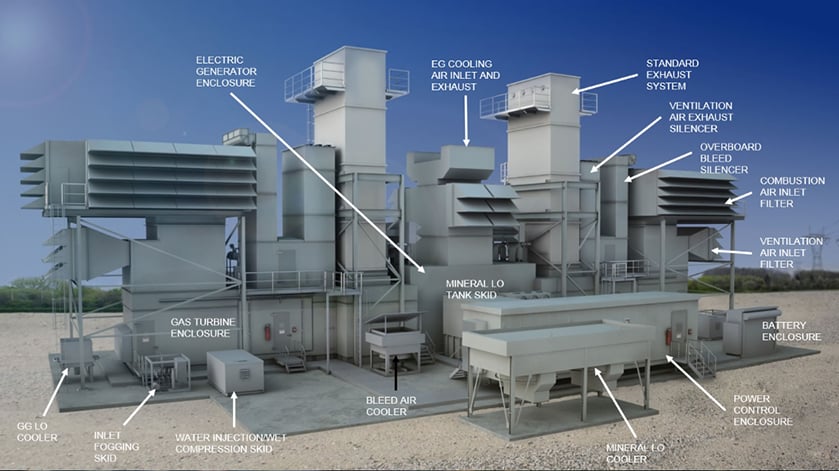

The FT4000® SWIFTPAC® unit is the world's largest-capacity aero-derivative gas turbine power supply package. The unit performs with a simple-cycle efficiency of 41% or higher and rated outputs of 70 to 140 MW. The FT4000 SWIFTPAC package has an optimal modular design, based on proven features of the FT8® gas turbine packages, that decreases site installation work.

Features

- Enables a start-up time of 10 minutes from cold start to full power with outstanding system stability

- High-performance, diversified operability based on the properties of independent-output turbines (free turbines)

- Reduced O&M cost and cost of ownership

- Quick engine change out affords high unit availability

Specifications

| Output | SWIFTPAC®70 | 60 Hz/50 Hz:70 MW |

|---|---|---|

| SWIFTPAC®140 | 60 Hz/50 Hz:140 MW | |

| Fuel | Dual Fuel (Gas/Oil) | |

| Start-up Time | 10 minutes (cold start to full power) | |

| Cooling Method | Air Cooling | |

| Type of Generator/ Voltage of SWGR | Open-ventilated Air Cooling/ 15 kV | |

| NOx Control | Water Injection | |

| Air Cooling | Yes | |

| Starting Method | Hydraulic | |

| Type of Ignition | Electric Spark | |

| Turning | Unnecessary | |

| Enclosure | Outdoor | |

| Power Turbine | Free Turbine | |

| Reduction Gear | Unnecessary | |

| Condensing Operation | Yes (without clutch) | |

Configuration (SWIFTPAC® 70)

| 50 Hz | 60 Hz | ||

|---|---|---|---|

| Compressor | Axial, multi-stage | ||

| Combustor | Annular | ||

| Turbine | Axial, multi-stage | ||

| Rotor | Build-up | ||

| Output (PT) | Free | ||

| Speed | rpm | 3,000 | 3,600 |

| Gas Turbine | Dimension | 9m×4m×4m | |

| Weight | 43t | ||

Performance (SWIFTPAC®70)

| 50 Hz | 60 Hz | ||

|---|---|---|---|

| ISO Base Rating | kW | 70,154 | 71,928 |

| Efficiency | % | 40.4 | 41.5 |

| LHV Heat Rate | kJ/kWh | 8,908 | 8,686 |

| Btu/kWh | 8,443 | 8,232 | |

| Exhaust Flow | kg/s | 183 | 183 |

| Exhaust Temp. | ℃ | 431 | 422 |

| F | 808 | 791 | |

| Start-up Time | Min | 10 (cold start to full power) | 10 (cold start to full power) |

Configuration (SWIFTPAC®140)

| 50 Hz | 60 Hz | ||

|---|---|---|---|

| Compressor | Axial, multi-stage | ||

| Combustor | Annular | ||

| Turbine | Axial, multi-stage | ||

| Rotor | Build-up | ||

| Output (PT) | Free | ||

| Speed | rpm | 3,000 | 3,600 |

| Gas Turbine | Dimension | 9m×4m×4m | |

| Weight | 43t | ||

Performance (SWIFTPAC®140)

| 50 Hz | 60 Hz | ||

|---|---|---|---|

| ISO Base Rating | kW | 140,500 | 144,243 |

| Efficiency | % | 40.5 | 41.6 |

| LHV Heat Rate | kJ/kWh | 8,896 | 8,661 |

| Btu/kWh | 8,431 | 8,209 | |

| Exhaust Flow | kg/s | 367 | 367 |

| Exhaust Temp. | ℃ | 431 | 422 |

| F | 808 | 791 | |

| Start-up Time | Min | 10 (cold start to full power) | 10 (cold start to full power) |

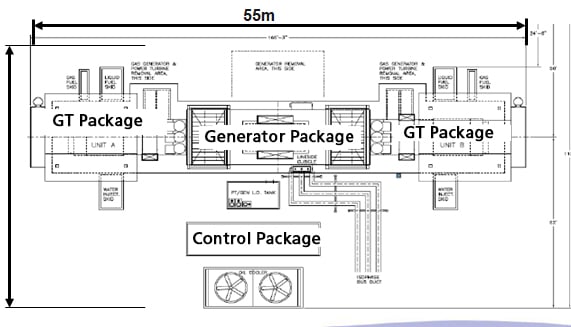

Arrangements (SWIFTPAC®140)

| Output | 140 MW (Water Injection, Inlet Air Cooling) |

|---|---|

| Fuel | Dual Fuel (Gas/Oil) |

| Cooling Method | Air Cooling |

| Foundation | Flat (non-pit) |

| Power Cable Connection | Quick-disconnect Cable |

Solution

・A system (FT4000®SWIFTPAC® 140) with two gas turbines in twin configuration driving one generator helps reduce the construction unit cost and installation area per output.

・Individual smaller HRSG/SCR recommended for each engine.

・The free turbine construction of the power turbine (PT) eliminates the need for reduction gears and helps reduce the capacity of the lubricating oil equipment while improving performance.

・No clutch is needed during synchronous condensing operation (control of system voltage by monitoring.)

FT4000® SWIFTPAC® Gas Turbine Package

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report