Combustor Technologies Supporting Stable Operation

Suppression of Combustion Pressure Fluctuation (Part 1)

Gas turbines used in power generation run mainly on natural gas. In high temperature combustion for high efficiency operation, the occurrence of combustion pressure fluctuation is the biggest issue when changing the fuel (or its property) supplied. Combustion pressure fluctuation refers to pressure fluctuations that occur inside the combustor. Excessive combustion pressure fluctuation may damage the combustor or turbine components.

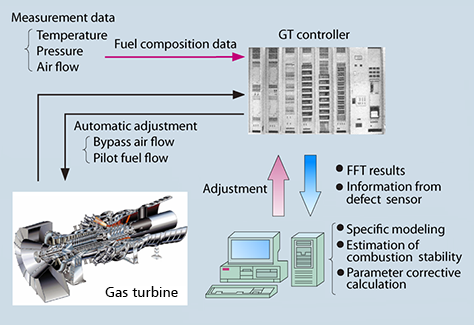

The combustion pressure fluctuation monitoring (CPFM) system takes measures when combustion pressure fluctuation occurs or adjusts the operation to avert the impact of combustion pressure fluctuation.

In the CPFM system, a sensor attached to the combustor constantly monitors combustion pressure fluctuation. When it occurs, the system lowers the load, executes an emergency stop or takes other measures to prevent damage to equipment.

To minimize the load change due to load reduction and emergency stops during the occurrence of combustion pressure fluctuation, an advanced combustion pressure fluctuation monitoring (A-CPFM) system is already commercialized. It automatically adjusts operation parameters to suppress combustion pressure fluctuation to ensure a state of constantly stable combustion.

Suppression of Combustion Pressure Fluctuation (Part 2)

Actions to address the combustion pressure fluctuation issue are conducted by means of the structural improvement of combustors.

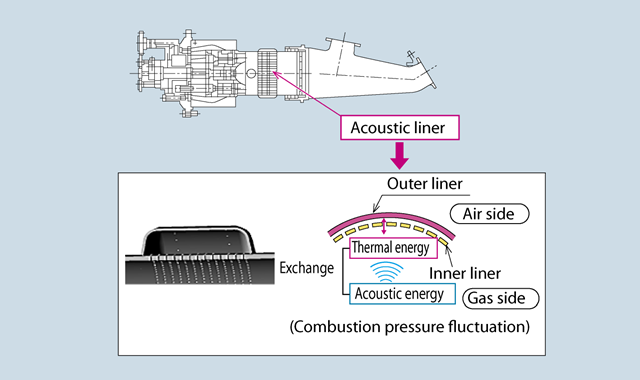

- An acoustic liner is provided to suppress combustion pressure fluctuation in the range of 500 Hz to 5,000 Hz.

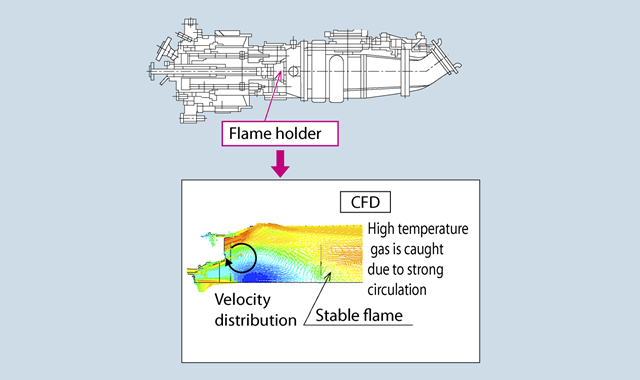

- The flame holder is improved to raise the temperature of the circulating flow and to increase flame holding capacity.

1. Acoustic Liner

2. Flame Holder

Low Calorie Gas Fuels

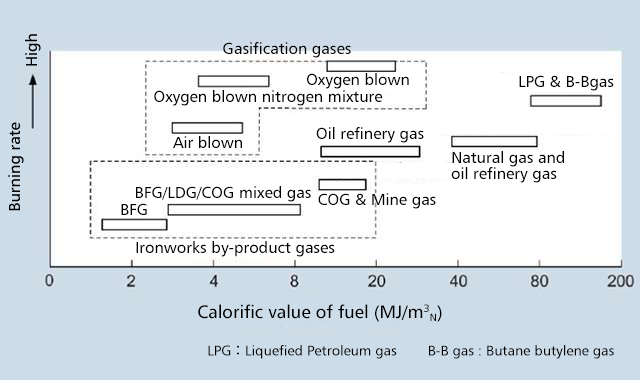

Typical low calorie gas fuels include gases generated from steelworks known as blast furnace gas (BFG), coke oven gas (COG) and Linz-Donawitz converter gas (LDG).

Mitsubishi Power has delivered a large number of high efficiency combined cycle plants using by-product gas from steelworks mentioned above to hold a worldwide market share of about 70% on an output basis.

- Blast furnace gas (BFG)

- Coke oven gas (COG)

- Linz-Donawitz converter gas (LDG)

- Liquefied petroleum gas (LPG)

- Butane butylene gas (B-B gas)

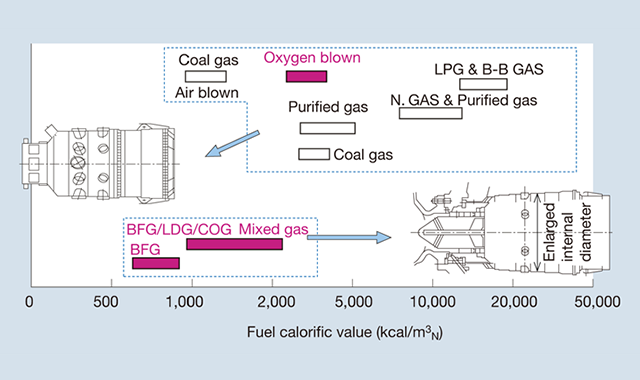

Combustors Compatible with Low Calorie Gas Fuels

Low calorie gas is lower in heat capacity and combustibility. It is difficult for any combustor with the same structure as that of natural gas to achieve stable combustion. To address different characteristics of low calorie gas, Mitsubishi Power applies its respective optimal combustor technologies.

| Features | Item to be considered | Solution technology |

|---|---|---|

| Limited combustion range | Control of the air ratio in the combustion area | Application of an air bypass valve |

| Low burning velocity | Decline in flow rate in the combustion area | Increase in diameter of the combustor |

| Need for a large amount of air for combustion | Reduction in the amount of cooling air | Application of a cooling method with high efficiency |

| Need for high fuel flow capacity | Suppression of the nozzle pressure loss | Application of a swirl nozzle |

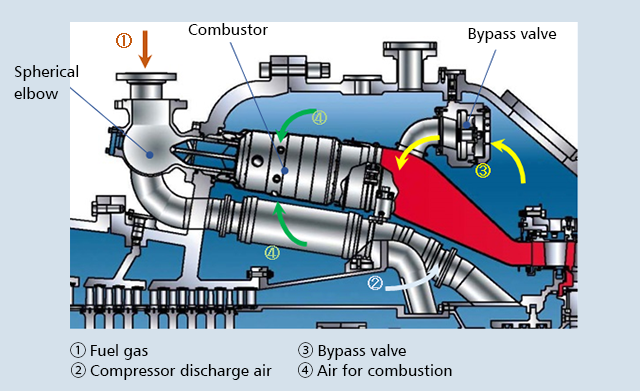

Response to a Limited Area of Combustion

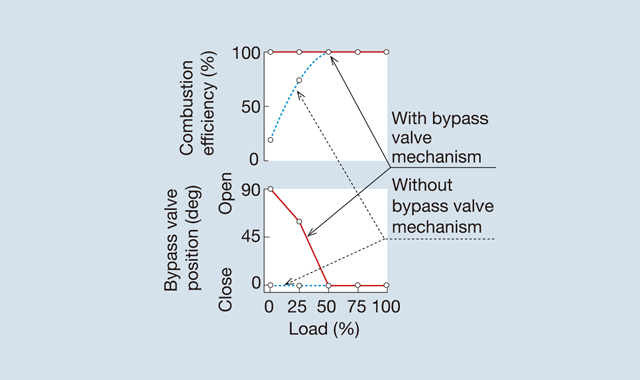

Low calorie gas has such a limited stable combustion area that it causes a loss of flame and fails to stably supply energy when combusted with a combustor for natural gas. Therefore, it is necessary to set an appropriate fuel/air ratio in the combustion range.

To resolve this problem, Mitsubishi Power has created an air bypass valve mechanism at the tail pipe of the combustor to ensure the correct fuel/air rate in the internal pipe within the combustion range. Absence of the bypass valve mechanism would lower combustion efficiency and impair combustibility under low load conditions with a low fuel/air ratio in the combustion range. With the mechanism provided, the valve opens under low load conditions to adjust the fuel/air ratio to an appropriate level to improve combustion efficiency.

Response to a Low Burning Velocity

Low calorie gas has a slow burning velocity. With the use of any combustor for natural gas, there is concern about combustion instability and incomplete combustion in the combustor.

The internal diameter of the combustor basket is increased to reduce the inner air flow speed. That helps to stabilize the flame and secure its retention time.

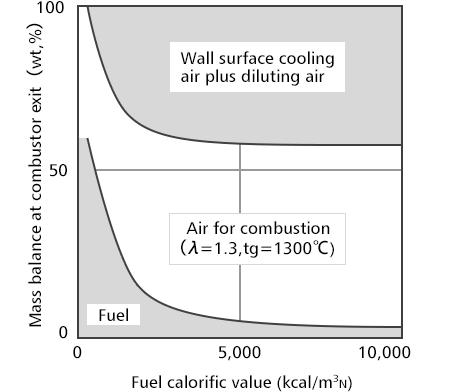

Response to the Need for a Large Amount of Air For Combustion

Low calorie gas generates a smaller amount of heat when burned than natural gas. It means that a large amount of fuel is needed. Meanwhile, the air flow rate is low.

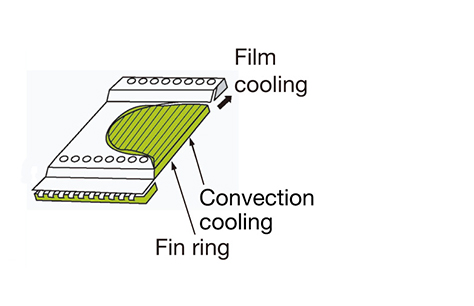

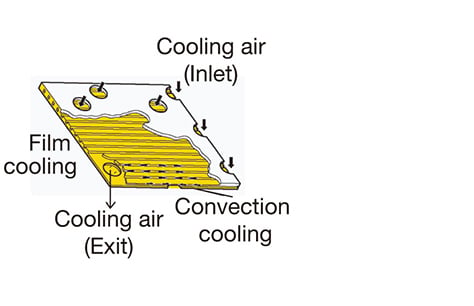

For cooling the combustor wall, Mitsubishi Power has introduced its unique high efficiency cooling systems, such as Plate Fin and MT Fin, to minimize the amount of air for cooling.

Response to the Need for High Fuel Flow Capacity

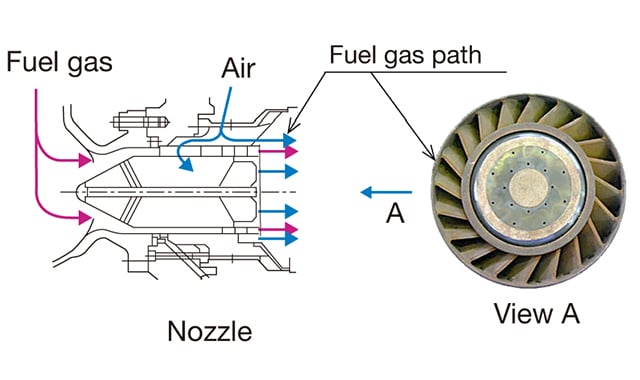

Blast furnace gas is so low in its fuel calorie level that it requires a fuel flow capacity that is nearly 10 times that of normal natural gas. With a single hollow nozzle as used in combustors for natural gas, the pressure loss at the nozzle is too great. In order to prevent this increase in pressure loss, blast furnace gas combustors adopt swirl nozzles with limited pressure losses at their nozzles.

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report