FGD Wastewater Treatment System

Wastewater generated from the wet FGD in coal fired thermal power plants is considered very difficult to treat.

There are multiple treatment methods even for one compound, and Mitsubishi Power offer the optimized solution for FGD wastewater treatment based on the influent conditions and effluent regulations.

FGD wastewater contains various compounds created from the coal, limestone, and used water dissolved in the FGD system and discharged to the wastewater treatment system.

Typical wastewater characteristics and treatment methods are shown in the following table.

In addition, COD, nitrogen (N) and selenium treatment methods are shown below as special treatment technologies. We also have boron treatment technology as well.

| Component | Treatment Method | |||||||

|---|---|---|---|---|---|---|---|---|

| Neutralization | Coagulation / Sedimentation | Granular Activated Carbon | Acid Degradation | Resin Adsorption | Chemical Degradation | Biological Treatment | ||

| pH | ○ | |||||||

| SS | ○ | △ | ||||||

| Fluoride (F) | ○ | ○ | ||||||

| COD | Organics | △ | ○ | △ | ||||

| Dithionate (*) | ○ | ○ | ||||||

| NS-Compounds (*) | △ | △ | ○ | |||||

| Heavy Metals | ○ | △ | ○ | |||||

| N | NH4-N | ○ | ○ | |||||

| NOX-N | ○ | |||||||

| Selenium (Se) | ○ Se4+ |

○ | ○ Se6+ |

|||||

| Boron (B) | ○ | ○ | ||||||

○: To be treated △: To be treated in the secondary removal effect

(*): Hard degradable material

Most of the chemical oxygen demand (COD) in wastewater is organic COD, and generally biological treatment or activated carbon adsorption is applied for treatment in the system.

On the other hand, for the difficult-to-treat COD generated in the wet FGD, the following system shall be applied to provide optimum treatment.

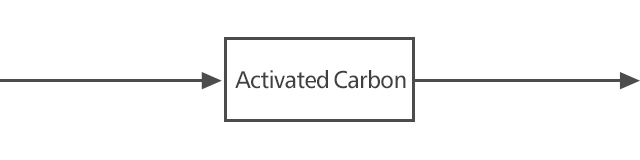

Organic COD Treatment

Source

- Concentration of organic matter supplied in make-up water

- Leaching from raw material (Limestone)

Typical Process

Outline

- Suitable for low concentration.

- Replacement required for activated carbon

Dithionate S2O6 COD Treatment

Source

Sulfur dioxide is absorbed in the absorber, and hydrogen sulfite ion is produced.

Dithionate is produced as a by-product of the oxidation of hydrogen sulfite.

2HSO3- + 1/2O2 → S2O62- + H2O

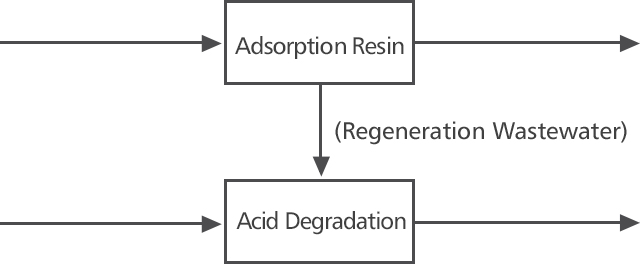

Resin Adsorption Method

Typical Process

Outline

- Dithionate is adsorbed on COD adsorption resin. Regeneration wastewater is heated at low pH, and dithionate is degraded to sulfate ion.

- Replacement required for resin

- Suitable for low concentration

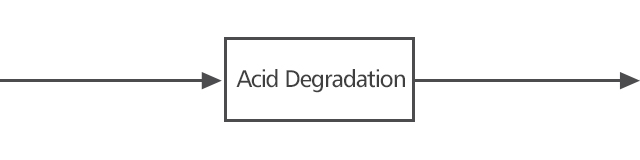

Acid Degradation Method

Typical Process

Outline

- Wastewater is directly heated at low pH, and dithionic acid is degraded to sulfate ion.

- Suitable for high concentration

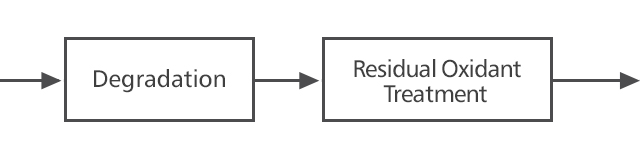

NS-Compounds Treatment

Source

Hydrogen sulfite ion reacts with NOX, and NS-compounds are produced.

Typical Process

Outline

- Oxidant dosed, sodium hypochlorite or sodium nitrite, and NS-compounds are degraded.

- Treatment required to reduce oxidant

Nitrogen compounds, such as ammonia, nitrate, nitrite, etc. are included in the wastewater generated by thermal power plants.

As ammonia treatment is required for FGD wastewater, fixed bed biological treatment, which can maintain microorganism adding a flexibility to the wastewater condition, can be adopted for fluctuating influent conditions.

This fixed bed system can maintain microorganism without nitrogen source injection even when the nitrogen level significantly reduces in the wastewater.

Comparison of fixed bed and floating bed biological treatment is shown in the following table.

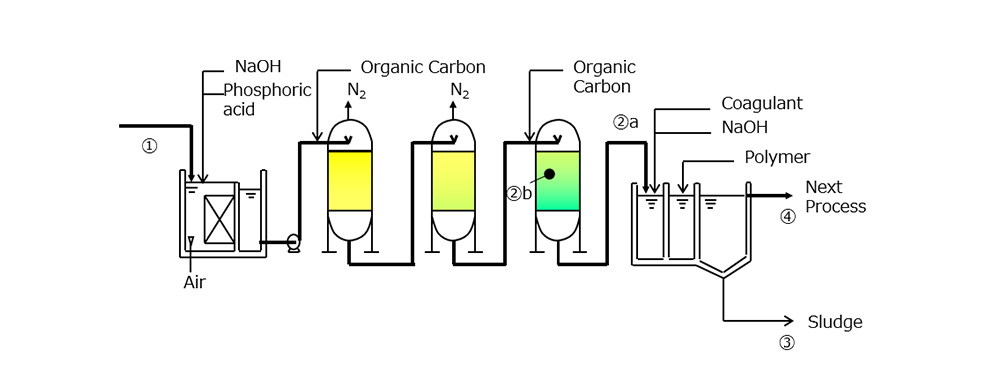

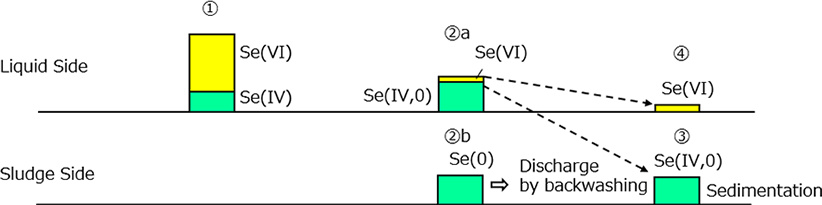

There are cases when FGD wastewater includes selenium, which has a toxicity similar to arsenic.

For selenium treatment, selenite (Se4+) can be treated by normal coagulation/sedimentation process, but selenate (Se6+) can hardly be removed by this process.

For selenate treatment, composite metal and/or biological treatment is popular, and we can offer the biological reduction system, which combines denitrification and selenate reduction treatment with excellent economy and high reliability.

- Selenate (Se6+) can be treated by using proper organic carbon source in the selenium reduction tower.

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report