Overview and Validation Status of T-Point 2 Demonstration Facility Gas Turbines

Combined Cycle Power Generation

T-Point 2 is located at Takasago Machinery Works in Hyogo Prefecture, Japan.

It is the only commercially operating power plant in the world that was specifically built for validation of power solutions.

Its uniqueness is the robust long-term validation process that minimizes risk for customers and gives assurance of product performance and durability for subsequent units of the same frame.

Purposes of the T-Point 2

- To validate gas turbine technologies newly applied to achieve higher efficiency, allow operations at elevated temperatures, and reduce NOx.

- To validate the reliability through long-term commercial operations of the highly efficient and environmentally friendly combined-cycle power generation.

Development of T-Point

The original T-Point demonstration facility began operation in 1997 with M501G (60 Hz), which was upgraded to M501J in 2010 and M501JAC in 2015 with response to the power industry’s demand for large-scale, high-efficiency power generation.

Since the original T-Point can not satisfy the further requirement for larger capacity and higher efficiency, we made a decision to build T-Point 2.

T-Point 2 entered full commercial operation with an enhanced JAC gas turbine from July 2020.

Validation of Next Generation

Combined Cycle Power Generation

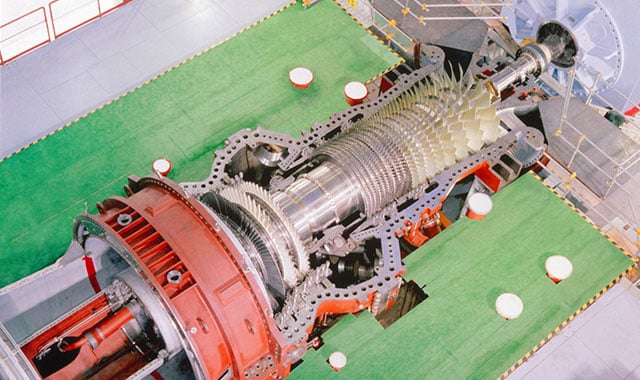

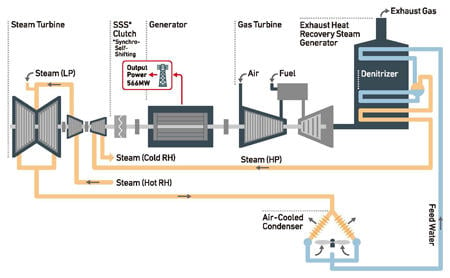

With its combination of gas turbine and steam turbine,T-Point 2 is cutting edge combined cycle power plant validation facility.

By developing next-generation technologies and validating them in T-Point 2 GTCC facilities, Mitsubishi Power helps its customers world-wide attain a stable electricity supply.

Long term demonstration of off-site plant control at T-Point 2 is conducted from the Mitsubishi Power Takasago TOMONI HUB (Analytics and Performance Center). Validation operations are run to increase the reliability of the entire plant including the main equipment such as turbines as well as auxiliary equipment such as pumps and fans. In addition, various applications of a suite of intelligent solutions TOMONI® that serve to shorten start-up time and automatically optimize operation parameters are installed in T-Point 2. Mitsubishi Power will persistently enhance its capabilities via validation at T-Point 2, which will subsequently enable the introduction of the Smarter Power Plant to the market.

| Item | T-Point | T-Point 2 | |

|---|---|---|---|

| Output (5℃ air temperature) |

330MW | 389MW | 566MW |

| Gas Turbine Type | M501G | M501J | M501JAC |

| Tarbine Inlet Temperature | 1,500℃ | 1,600℃ | 1,650℃ |

| Year Operation Started | 1997 | 2011(replacement date) | 2020 |

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report