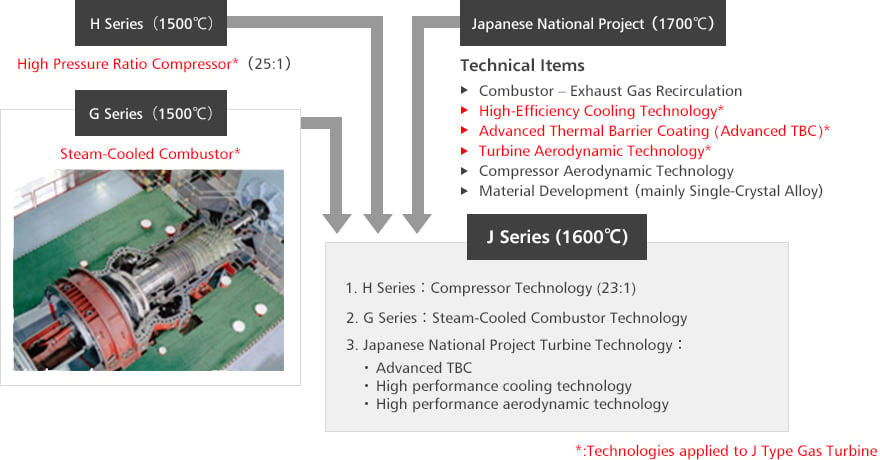

Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

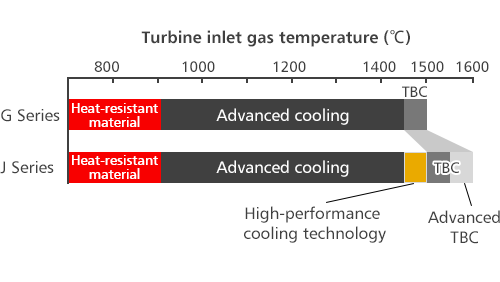

The J-Series gas turbines incorporate elemental technologies proven with the F-Series, featuring the turbine inlet temperature of 1,400°C class to hold a proven track record in operation as well as with the 1,500°C class G-Series. In addition, achievements in research and development for the cutting-edge 1,700°C class technology in Japanese national projects (See Note) are applied to pave the way for their operation at a turbine inlet temperature of 1,600°C class.

- Development of elemental technologies for the practical application of high efficiency gas turbines (2004-2007)

Development of technologies for the practical application of high efficiency gas turbines (2008-2011)

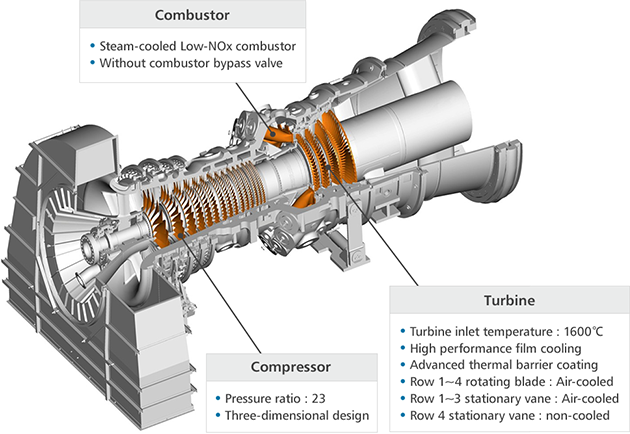

Technical Features of the J-Series

Compressor

Cutting-edge 3D technology is applied to reduce the shock wave loss in the initial stage and the frictional loss in the intermediate and final stages. These results were evaluated with 3D CFD-based analysis and verified with the high-speed operation test using a scale model.

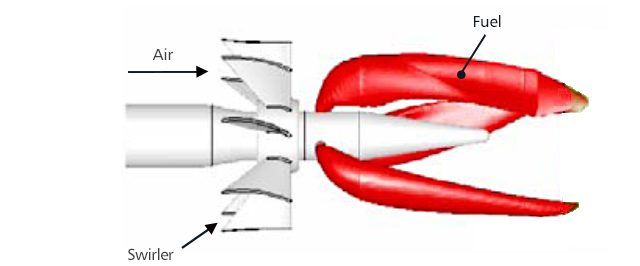

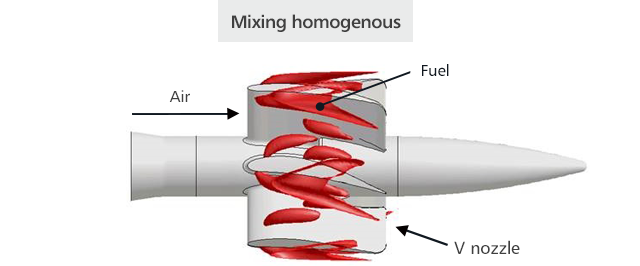

Combustor

The turbine inlet temperature is 1,600°C, which is 100°C higher than that of the G-Series. Combustor nozzles have been improved for more uniform mixing of fuel with air and low-NOx technologies for lowering the local flame temperature in the combustion area and have been applied to attain a NOx emission concentration equivalent to that of the G-Series.

Turbine

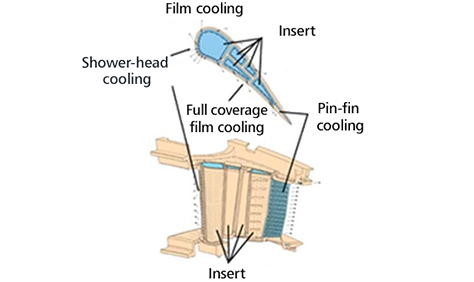

In addition to the fully 3D design, the turbine aerodynamics technology developed in Japanese national projects is applied. For a temperature increase from the G-Series, the high performance cooling technology and the advanced thermal barrier coating (TBC) technology developed in Japanese national projects are employed.

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report