Once-through Boilers

Overview

Once-through boilers are able to produce steam at higher pressures and temperatures than drum boilers.

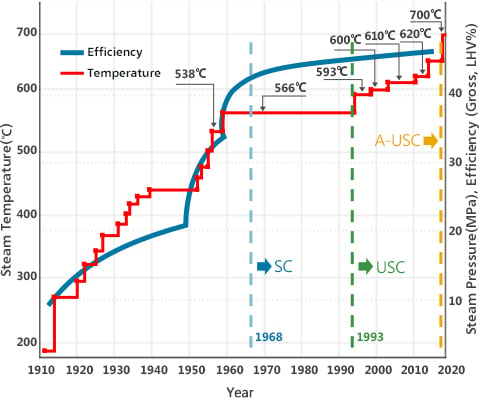

In thermal power plants, raising steam conditions (pressure and temperature) can enable efficiency gains in power generation equipment, allowing an operator to reduce its fuel consumption and CO2 emissions. Mitsubishi Power delivered its first supercritical pressure once-through boiler in 1968, and followed up in 1981 with delivery of the first supercritical variable pressure once-through boiler. In 1993, Mitsubishi Power sought to further improve steam conditions, culminating in delivery of the first ultra-supercritical variable pressure once-through boiler.

Mitsubishi Power boasts an extensive delivery track record for both supercritical and ultra-supercritical variants and conditions to deliver highly reliable boilers.

Specifications

-

2-Pass Boiler

Output Up to 1,070MW Main steam flow rate Up to 3,210ton/h Steam temperature Up to 600/610°C Steam pressure Up to 31 MPa -

Tower Boiler

Output Up to 1,100 MW Main steam flow rate Up to 2,939ton/hr Steam temperature Up to 600/620°C Steam pressure Up to 30.5 MPa

Delivery Records

-

Customer JERA Co.,Inc. Plant (Country) Hitachinaka Thermal Power Station Units 1 and 2 (Japan) Scope of delivery Boilers, turbines and generators (ETK) Output 1,000 MW x 2 Maximum continuous rating 2,870t/h Steam conditions Main steam temperature 600°C Reheat steam temperature 600°C Main steam pressure 24.6 MPaA Fuel Bituminous coal / subbituminous coal Start of operation 2003 / 2013 -

Customer JERA Co.,Inc. Plant (Country) Hirono Thermal Power Station Units 5 and 6 (Japan) Scope of delivery Boilers, turbines and generators (ELT) Output 600 MW × 2 Maximum continuous rating 1,770t/h Steam conditions Main steam temperature 600°C Reheat steam temperature 600°C Main steam pressure 24.6 MPaA Fuel Bituminous coal / subbituminous coal Start of operation 2003 / 2013

-

Customer RWE Plant (Country) Neurath Power Station (Germany) Scope of delivery Boilers Output 1,100 MW Maximum continuous rating 2,870t/h Steam conditions Main steam temperature 600°C Reheat steam temperature 605°C Main steam pressure 27.2 MPaA Fuel German brown coal Start of operation 2012 -

Customer PT Paiton Energy Plant (Country) Paiton III Thermal Power Plant (Indonesia) Scope of delivery Full turnkey Output 866 MW Maximum continuous rating 2,695t/h Steam conditions Main steam temperature 538°C Reheat steam temperature 566°C Main steam pressure 24.5 MPaA Fuel Subbituminous coal Start of operation 2012

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report