Pulverizers

To efficiently combust coal, it needs to be pulverized into fine particles (100μm) before being placed in a boiler.

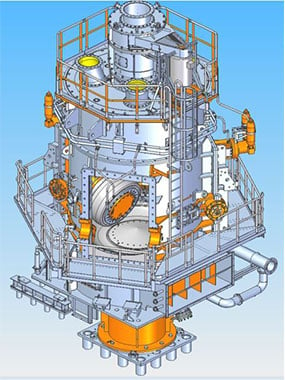

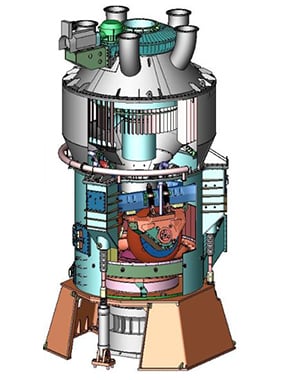

A pulverizer (coal pulverizer) is installed for this purpose, and pulverizes pieces of coal several centimeters in diameter down to fine particles. The pulverizer includes pulverization, drying and classification functions. The classification function plays the important role of ensuring that only fine particles are sent to the boiler. A rotating-type classifier ensures that only fine particles pass through and cuts coarse particles through the opposing balance of centrifugal force and centripetal force produced by a blade rotating at several dozen rpm and the flow of air.

A vertical-type pulverizer bites into coal between a rotating table and roller to pulverize the coal through the action of crushing and grinding. Mitsubishi Power offers a varied lineup from small to high capacity through two types of pulverizer, MVM and MPS.

Overview

- Achieving a high concentration of pulverized coal

- Removing coarse particles through effective classification performance

- High combustion efficiency in the boiler

- Lower NOx emissions and unburnt coal

- High capacity and low power consumption

Specifications

| Models | MVM, MPS |

|---|---|

| Supported fuels | Coal (Bituminous coal, subbituminous coal), biomass, PC (petroleum coke) |

| Capacity | 9-145t/h |

| Fineness of pulverized coal | 70-95% pass through a 200 mesh screen |

| Classification methods | Rotating Separator / Fixed Separator / Combined Rotating + Fixed Separator |

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report