Net IR-S Infrared Flame Detector

Overview

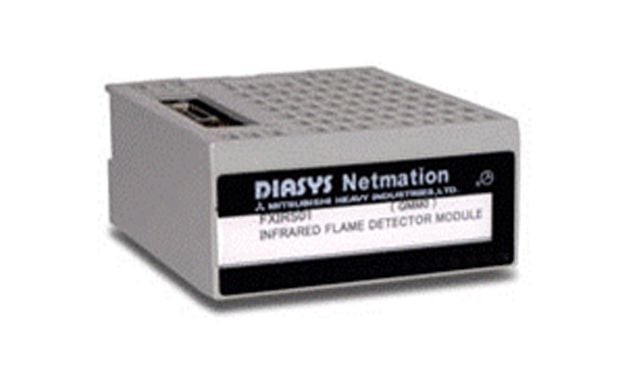

To meet the demands of modern monitoring and control systems in place at thermal power plants, the Net IR-S Infrared Flame Detector combines the proven IR-S type flame detector that has been successfully installed in many power plants with Mitsubishi Power' DIASYS Netmation control system, resulting in a flame detector product that functions as a burner control system.

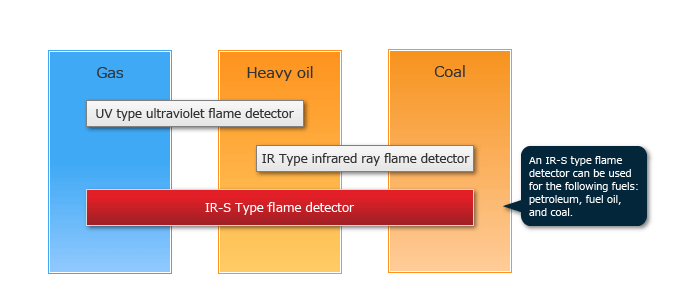

The sensor unit of Net IR-S is the same as a conventional IR-S sensor and can be used for any of the following fuels: fuel oil, coal and gas. In addition, the superb detection reliability, maintainability and cost performance of the IR-S sensor are maintained.

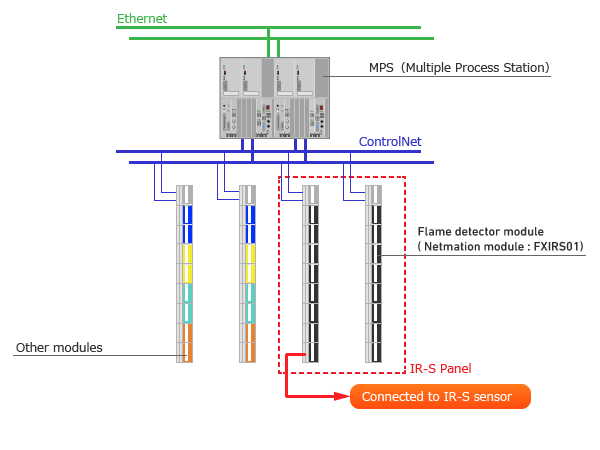

Furthermore, the decision circuit is built as a module of DIASYS Netmation. It is used along with an upper layer of Netmation to offer an easy-to-use interface. The panel of Net IR-S can be designed so that the Net IR-S works as a stand-alone flame detector system independent from a burner control system.

If you replace a conventional flame detector with this new type, the pre-existing equipment can be reused.

| Equipment Name | Existing Methods of Flame Detection | |

|---|---|---|

| UV Type | IR Type | |

| Sensor Unit | Replaced | Replaced |

| Flame Detector Panel | Replaced | Replaced |

| Sensor Cable | Reused | Replaced |

| Guide Pipe | Reused | Reused |

| Cooling-air Piping | Reused | Reused |

| Cooling Fan | Reused | Reused |

Features

High sensitivity design

High sensitivity to the intensity of flame enables stable detection of the burner flame. The flame is detected through the unlit zone.

Extended detection range

The sensor has 100 times dynamic range of a conventional product and allows stable detection from slow combustion to a high intensity flame. No sensitivity adjustment is required for the sensor at the site.

Maintenance free

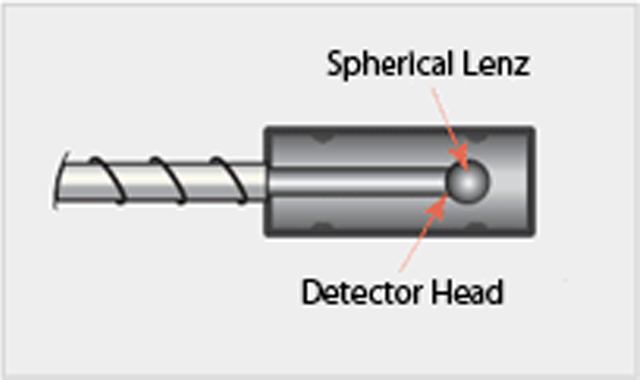

A ball lens is used to eliminate the need to clean the sensor window during boiler normal operation.

Long-life sensor

Because a long-life infrared semiconductor sensor element is used, periodic replacement is not necessary.

Decreasing the number of panels

The detector unit is compact with a space-saving design which allows one panel to incorporate 40 corners.

Reuse of existing boiler facilities

When you replace a flame detector, work is not necessary for the boiler itself.

Reuse of cable

Changing the cable between the sensor and the panel is not necessary. (When the existing system uses UV-type detection)

System Configuration

Flame Detector Panel

Net IR-S Infrared Flame Detector

Flame Detector Panel

Flame Detector Module

Flame Detector Main Unit

Flame Detector Main Unit

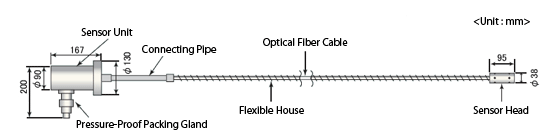

Cross Sectional View of Sensor Head

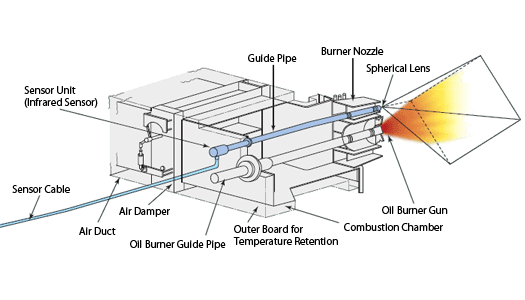

For Fuel Oil Burner

The following example applies to a fuel oil burner.

Specifications

Sensor Unit

The specifications of the sensor unit are as follows.

| Structure | Explosion-proof (Exd II BT4), waterproof | |

|---|---|---|

| Dimensions | Entire Length | Optional |

| Guide Pipe | 50A (40A) | |

| Detection Wavelength | 500 - 1,100nm | |

| Allowable Temperature | Sensor Tip | Not exceeding 400℃ |

| Inside of Guide Pipe | Not exceeding 200℃ | |

| Amplifier | Not exceeding 60℃ | |

| Cooling Air | Air Pressure | In-furnace pressure+150mmAq |

| Air Flow | 15Nm3/min per sensor | |

Flame Detector Panel

The specifications of the flame detector panel are as follows.

| Dimensions | 2,300mm (H) ×810mm (W) ×800mm (D) | |

|---|---|---|

| Configuration |

|

|

| Output Signals | Flame on | 1a |

| Low luminance level | 1a | |

| Power loss | 1b | |

| Contact capacity | DC125V / AC120V 0.5A | |

| Ambient Temperature | 0 to 50℃ | |

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report