M501J Series

-

Standalone Gas Turbine Output

453 MW class

-

Combined Cycle Output

664 MW class / 1,332 MW class

-

Combined Cycle Efficiency

More than 64%

-

High Reliability Verified

Cumulative total number of hours of operation as commercial unit:More than 3 million hours

(J-series Date as of May 2025)

Cutting-edge high-capacity gas turbines for 60 Hz power generation

incorporating state-of-the-art technologies

The J Series gas turbines are an integration of the proven G Series and elemental technologies for temperature increase as a result of the Japanese national project for the development of 1,700°C class gas turbines. They operate at a turbine inlet temperature of 1,600°C. The M501JAC Series gas turbines adopt air cooling for combustors instead of steam cooling. With a performance equivalent to the M501J Series gas turbines, they produce a high level of operability including a shorter start-up time.

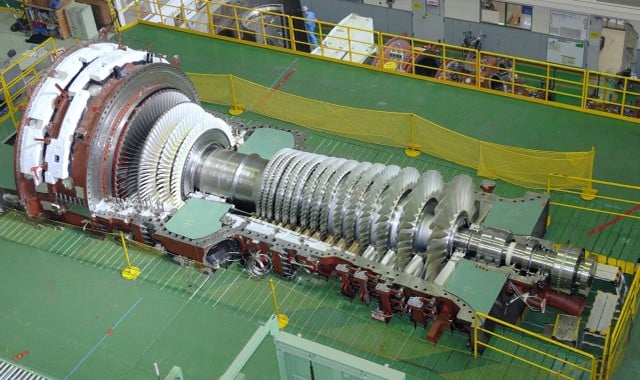

Overall Design

The gas turbine unit is based on the basic structure adopted in the early 1970s that has accumulated a track record of at least 50 years. Its main features are as follows:

- A compressor shaft end drive reduces the effect of thermal expansion on alignment

- A rotor with simple single-shaft two-bearing support

- A rotor structure has bolt-connected discs with the torque pins in the compressor section and CURVIC couplings in the turbine section to ensure stable torque transmission

- An axial flow exhaust structure advantageous in combined cycle plant layouts

- Horizontally split casings that facilitate field removal of the blades with the rotor in place

Compressor

Advanced three-dimensional design techniques are used to improve performance while reducing the shockwave loss in the initial stages and frictional loss in the intermediate and final stages. The inlet guide vanes and variable stationary vanes at the first three stages are controlled to ensure stable operation at the start-up and enhanced performance at partial load in combined cycle operation.

Combustor

The J Series combustor is based on the steam cooling system proven with the G Series. An improved fuel nozzle is used to help produce a more homogeneous mixture of fuel and air. Despite the rise in turbine inlet temperature, the combustor attains NOx emission concentration equivalent to that of the G Series.

Incorporating air-cooled combustors, the JAC series adds operational flexibility by eliminating any need for steam cooling from the bottoming cycle.

Turbine

The turbine inlet temperature is 100°C higher than that of the G Series. However, the application of high performance cooling technologies developed in a Japanese national project for the development of 1,700°C class gas turbines and advanced thermal barrier coating (TBC) helps to maintain the metal temperature of the turbine blades at the level of conventional gas turbines.

Configuration

| M501JAC | ||

|---|---|---|

| Compressor | Number of Stages | 15 |

| Combustor | Number of Cans | 16 |

| Cooling Method | Air Cooled | |

| Turbine | Number of Stages | 4 |

| Rotor | Number of Rotors | 1 |

| Output Shaft | Cold End | |

| Rated Speed | 3,600 rpm | |

| Gas Turbine | Approx. L × W × H | 15.0 × 5.6 × 5.6 m |

| Approx. Weight | 347 ton | |

Simple Cycle Performance

| M501JAC | ||

|---|---|---|

| Frequency | 60 Hz | |

| ISO Base Rating | 453 MW | |

| Efficiency | 44.0 %LHV | |

| LHV Heat Rate | 8,182 kJ/kWh | |

| 7,755 Btu/kWh | ||

| Exhaust Flow | 815 kg/s | |

| 1,685 lb/s | ||

| Exhaust Temperature | 649 °C | |

| 1,193 °F | ||

| Exhaust Emission | NOx | 25 ppm@15%O2 |

| CO | 9 ppm@15%O2 | |

| Turn Down Load | 50 % | |

| Ramp Rate | 42 MW/min | |

| Starting Time | 30 minutes | |

Combined Cycle Performance

| M501JAC | ||

|---|---|---|

| 1 on 1 | Plant Output | 664 MW |

| Plant Efficiency | >64.0 %LHV | |

| 2 on 1 | Plant Output | 1,332 MW |

| Plant Efficiency | >64.2 %LHV | |

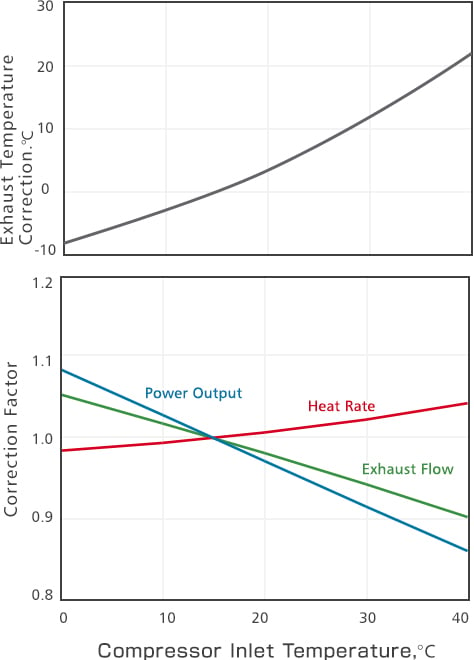

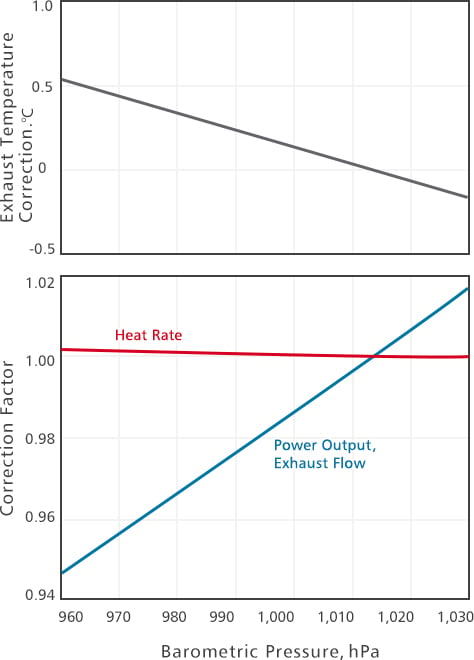

Performance Correction Curves

-

Effects of Compressor Inlet Temperature on Gas Turbine Performance (Typical)

-

Effects of Barometric Pressure on Gas Turbine Performance (Typical)

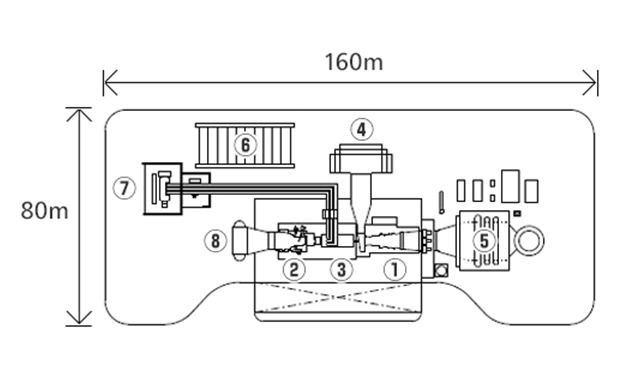

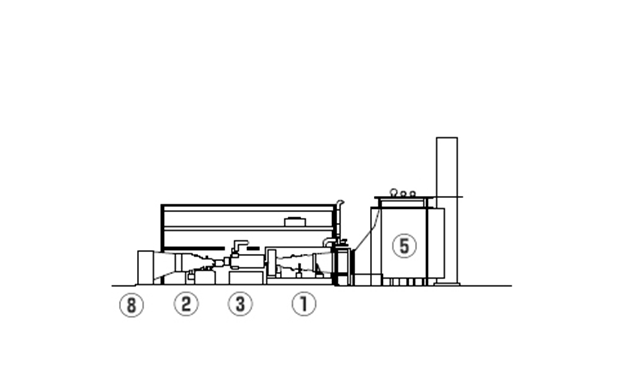

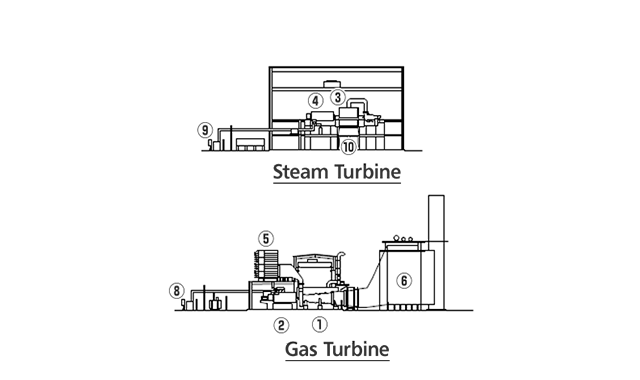

Typical Plant Layout - 1 on 1 configuration, single-shaft

- Gas Turbines

- Steam Turbines

- Generators

- Inlet Air Filter

- Heat Recovery Steam Generator (HRSG)

- Electrical / Control Package

- Main Transformer

- Condenser

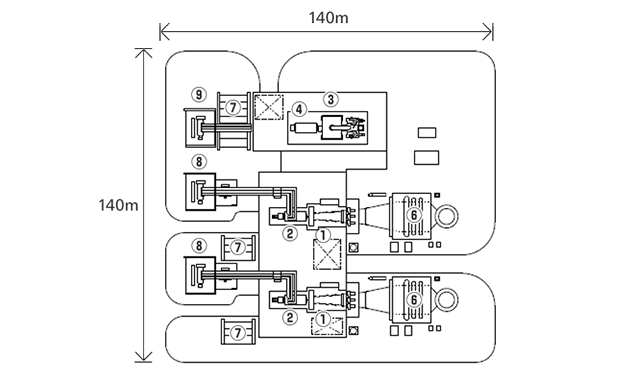

Typical Plant Layout - 2 on 1 configuration

- Gas Turbines

- GT Generator

- Steam Turbines

- ST Generator

- Inlet Air Filter

- Heat Recovery Steam Generator (HRSG)

- Electrical / Control Package

- GT Main Transformer

- ST Main Transformer

- Condenser

Delivery Records Example

Himeji No. 2 Power Station, The Kansai Electric Power Co., Inc. (Japan)(Photo courtesy of The Kansai Electric Power Co, Inc.)

2,919 MW, 6 x M501J

PTK-2, Korea Western Power Co., Ltd. (Korea)

950 MW, 2 x M501J

Ulsan Power Plant, Korea East-West Power Co., Ltd. (Korea)

950 MW, 2 x M501J

Yulchon Power Plant, MPC Yulchon Generation Co., Ltd. (Korea)

950 MW, 2 x M501J

Order Results Example

| Number of units x Series | Year of start of operation | Plant specifications | |

|---|---|---|---|

| Greensville County Power Plant, Virginia Electric and Power Company (VEPCO) (USA) | 3 × M501J | 2018 | Combined cycle |

| Noreste Power Plant, Comisión Federal de Electricidad (CFE) / Iberdrola (Mexico) | 2 × M501J | 2018 | Combined cycle |

| Shin Pyeongtaek Power Co., Ltd. (Korea) | 2 × M501J | 2019 | Combined cycle |

| Westmoreland Generating Station, Tenaska (USA) | 2 × M501J | 2019 | Combined cycle |

| Noreste Power Plant, Comisión Federal de Electricidad (CFE) / Iberdrola (Mexico) | 2 × M501J | 2019 | Combined cycle |

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report