Simulator

Overview

As a leading manufacturer of thermal power plants, Mitsubishi Heavy Industries has utilized its wealth of experience to commercialize training simulators for conventional plants, gas turbine combined cycle (GTCC) plants, integrated coal gasification combined cycle (IGCC) plants, and circulating fluidized bed (CFB) plants. The training simulators are included in the product lineup for its DIASYS integrated control system, which employs the latest information, communication and control technologies. Mitsubishi Heavy Industries delivers these training simulators to customers all over the world.

Solutions Offered by Training Simulators

The training simulators are able to offer a variety of solutions including:

Operation Training

- Training on plant operation for operators (start/stop/special operations in each mode)

- Troubleshooting by operators (accident response training)

Maintenance Training

- Mastering how to use the monitoring and operation tools for control logic

- Operational verification and analysis carried out before control logic is updated for control improvement

Control and Model Training

- Control logic training

- Plant model training

Features of Training Simulators

High-precision Plant Models Created by a Plant Manufacturer with Knowledge of the Equipment Down to the Last Detail

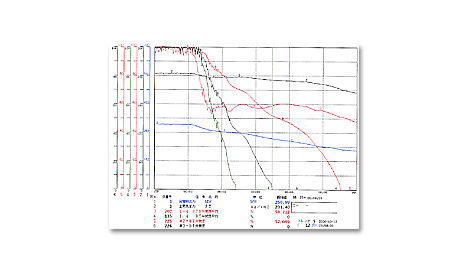

Precise mathematical models based on physical laws of physics, fluid mechanics, thermodynamics, and electrodynamics are used to offer high-precision simulation representable of actual plants.

Various Types of Plant Models

- Gas turbine models

- Steam turbine models

- Boilers/Heat Recovery Steam Generators (HRSG)

Circulating Fluidized Bed (CFB) boilers - Generators

- Other plant auxiliary equipment

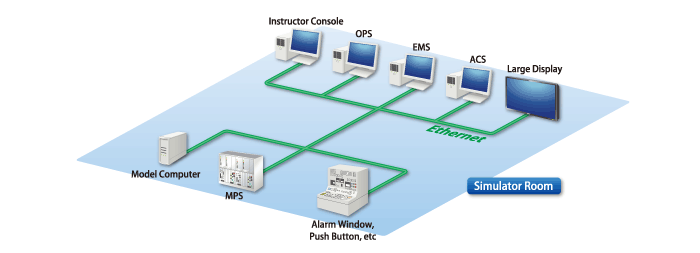

The Same Netmation Software and Database as an Actual Plant

The simulator can use the same Netmation software (operator station (OPS), engineering & maintenance station (EMS), and accessory station (ACS)) used in an actual plant, allowing effective operation training.

The simulator can also use the same logic and graphic database as an actual plant, allowing verification before updating control logic and maintenance training for parameter tuning.

| Operator Station (OPS) | Terminal to perform monitoring and operation. |

| Accessory Station (ACS) | Terminal to perform data collection and form creation. |

| Engineering & Maintenance Station (EMS) | Engineering functions for system development and maintenance control. |

| Multiple Process Station (MPS) | Control equipment to perform plant control operation and site ON/OFF control. |

Various Types of Simulators to Meet All Kinds of Needs

Full Replica Type Simulator 1 (for Operation Using the Control Panel)

Full Replica Type Simulator 2 (for CRT Operation Type)

Compact Type Simulator (Available for Multiple-PC or Single-PC Configuration)

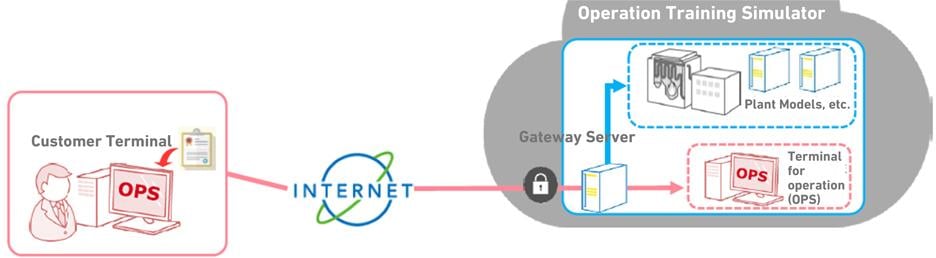

Cloud System

Simulator Functions

The simulators have various features to support training and verification.

- Plant start/stop training: Basic training for starting and stopping a plant:

- Plant abnormality response training: Learning of operations for recovery from abnormal plant equipment state

- Control logic ideological education: Learning of the control logic structure and parameter design philosophy

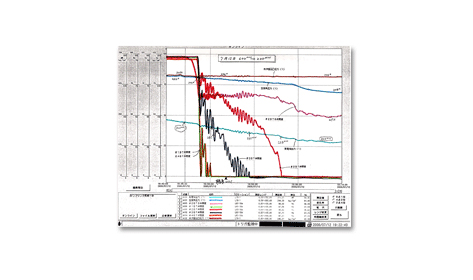

- Actual machine operation reproduction simulation: Preliminary testing study by using reproduction simulation before actual machine test.

Instructor Console Functions

Optional Functions

· Training Operation Evaluation Function

This function comprehensively determines operation results such as trend graphs and alarm logs, and then indicates the results by points.

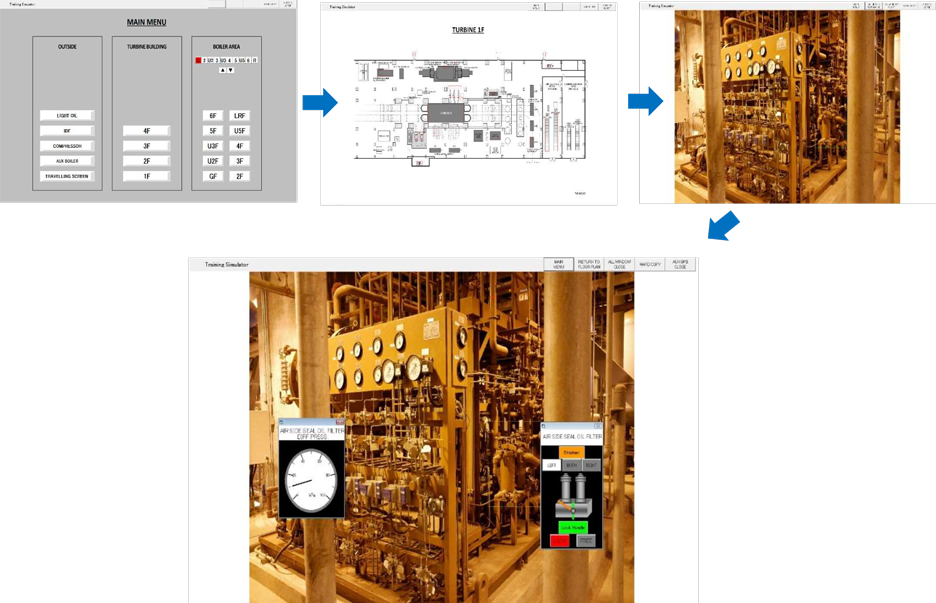

· Simulation of Field Operation Function

Accident response training might require on-site situation confirmation and operation. By using on-site screens created based on actual photographs, trainees can learn response operations that have practical use.

The menus for accessing on-site equipment use the floor layout maps as much as possible so that access to on-site equipment is also included in training.

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report