Gas Turbines for Mechanical Drive Applications

H-100 Series gas turbines are suited for mechanical drive applications, especially for driving compressors in LNG plants.

Features

- The H-100 Series models are applicable for 4 to 6 million tons per annum (MTPA) class LNG plants

- Variable speed operation

- Start-up with a fully loaded compressor

- No helper motor and variable frequency driver (VFD) required

- High nitrogen (N2) fuel applicability

- Reliability: more than 99%

- Integrated into a gas turbine and compressor package in collaboration with Mitsubishi Heavy Industries Compressor Corporation as the MHI Group

| Item | H-100 | |

|---|---|---|

| ISO rated output | 144,350 hp | 160,780 hp |

| Rotational Speed | 3,600 rpm (2,520 rpm to 3,780 rpm) |

3,000 rpm (2,100 rpm to 3,150 rpm) |

| Thermal efficiency | 38.9% LHV | 38.9% LHV |

| Heat rate (LHV) | 6,542 Btu/hp-hr | 6,549 Btu/hp-hr |

1. Features Suited for Large Capacity LNG Plants

The H-100 Series is not only suitable for combined cycle power plants. Characterized by its two-axis construction, they are also suited as gas turbines for driving compressors in large capacity (4 to 6 MTPA) LNG plants.

2. Variable Speed Operation

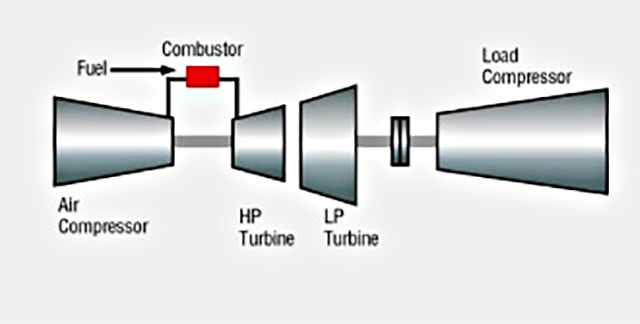

The H-100 Series gas turbines have a two-shaft structure. Low pressure (third and fourth stage) turbine is separated from high pressure turbine, i.e. air compressor and first and second stage turbine. It means that they can be operated at a wide ranges of speed without constraints arising from the limit on revolutions as in high pressure turbines. That helps reduce the risk of an emergency stop following a sudden load change on the compressor or the LNG process driven by the turbine.

3. Start-up with a Fully Loaded Compressor

The H-100 Series gas turbines have a two-shaft structure. It allows them to be restarted without reducing the pressure in the cooling process system after the LNG plant enters an emergency stop situation for some reason.

Advantages to customers

- Omission of pressure reduction procedures (facilitation of operation)

- Cutting the restart time by around three hours to improve LNG production

- Reduction of operation costs

4. No Need for Helper Motors and VFDs

The H-100 Series has a two-shaft structure, and a small torque is required for start-up. It produces a greater output than the single-shaft turbines commonly introduced to large capacity LNG plants and eliminates the need for helper motors and VFDs. It can be started up with a start-up motor that has an approximate output of 1 MW and a torque converter. It paves the way for a simpler electrical equipment configuration and lower power consumption. As mentioned above, the start-up system is simple. It produces a torque that surpasses the breakaway torque of a compressor driven under full load pressure.

Advantages to customers

- Lower power consumption for start-up and omission of large capacity start-up equipment (helper motor), resulting in space saving and omission of electrical facilities

- High reliability and availability (reduction of trip items and simple system configuration)

- Easing of maintenance work

5. Support for High Nitrogen (N2) Content Fuels

Verified combustion technology makes the gas turbines compatible with fuels that have a broader range of Wobbe Index (WI) value. It means that they support high N2 content fuels.

6. The MHI Group’s Responsibility for Packaging

When a compressor is supplied from Mitsubishi Heavy Industries Compressor Corporation, the MHI Group will prepare a package comprising a gas turbine and a compressor to provide it for customers.

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report