Product Lineup

Gas Turbines

Mitsubishi Power has a wide range of gas turbines from the 30 MW class to the 570 MW class to meet diverse needs around the world.

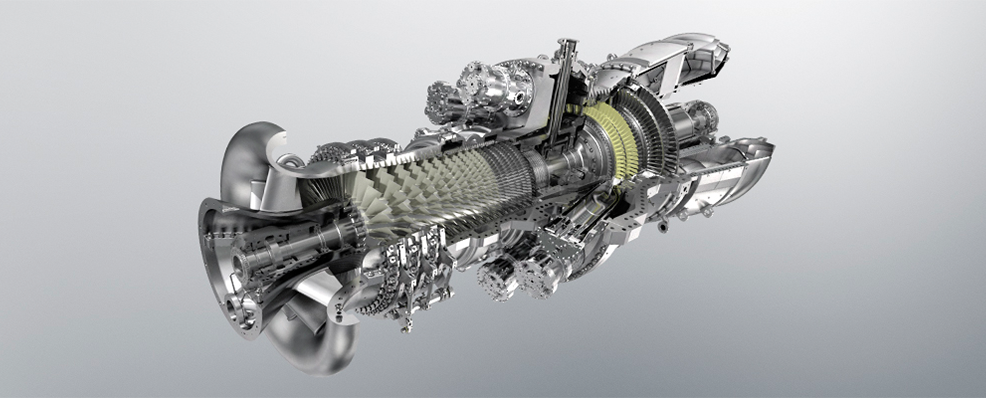

Middle and Small Capacity Gas Turbines

(40 MW to 120 MW class)

Features

-

- Heavy duty models with high reliability

- Reliability of more than 99% (actual operating time of more than 13.7 million hours)

- Heavy duty models with high reliability

-

- Low environmental impact combustor compatible with a wide variety of fuels

- Natural gas, LPG, off gas, syngas, light oil, kerosene and bio-ethanol

- Low environmental impact combustor compatible with a wide variety of fuels

-

- High efficiency

- Overall efficiency of more than 80% at the combined heat and power (CHP) plant using exhaust gas from the gas turbine

- High efficiency

-

- An optimal combined plant meeting various power demands

- A lineup of models with an output range from 60 MW to 350 MW and a high plant efficiency of 55-58%

- An optimal combined plant meeting various power demands

-

- Support for flexible operation

- The investment can be recovered in several years.

- High load responsivity to support daily start and stop (DSS) operation

- Easy on-site maintenance

Diagnostic Program

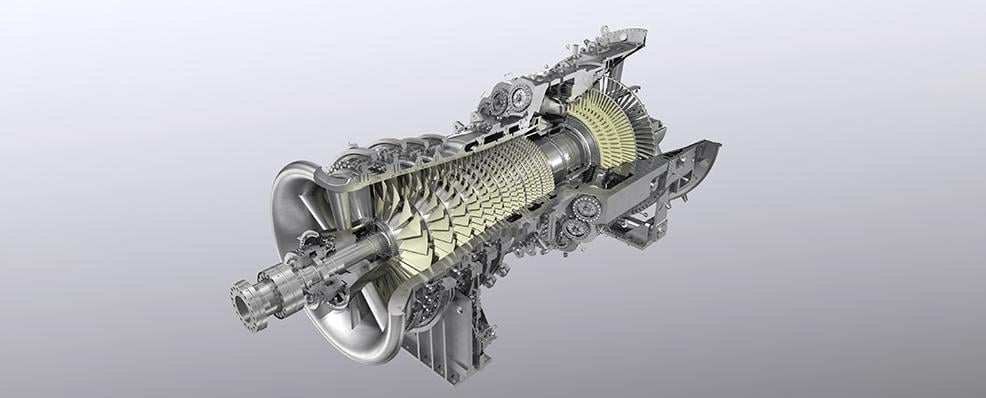

Large Capacity Gas Turbines

(120 MW to 570 MW class)

Features

-

- Combined cycle plant performance with world-leading efficiency

- Plant efficiency of more than 64%

- Combined cycle plant performance with world-leading efficiency

-

- Low environmental impact combustor

- Mitsubishi Power Dry Low NOx combustor

- Low environmental impact combustor

-

- Applicable to combined heat and power plant

- High load responsivity to support daily start and stop (DSS) operation

For 60 Hz

For 50 Hz

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report