Total AQCS Solution

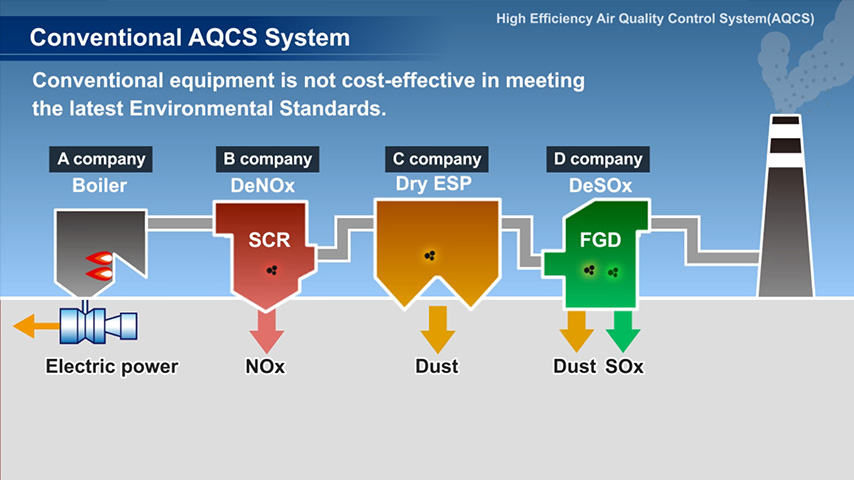

Mitsubishi Power is one of the few companies able to develop its own technology for the total AQCS area and is capable of designing the total AQCS area to meet commercial and/or environmental needs. We can make your fossil fuel power plant environmentally compatible.

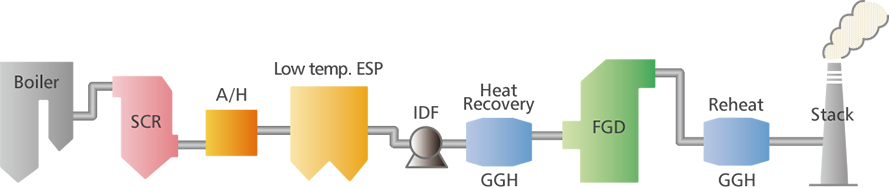

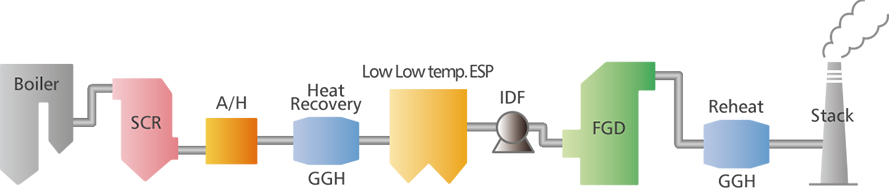

We have developed a new flue gas treatment system, consisting of the ESP, FGD, and non-leakage gas-gas heater (GGH), which realizes effective treatment of flue gas so that the system can maintain dust emissions to well within stringent regulations.

Furthermore, in urban area where more stringent regulations are required, wet ESP will be installed downstream of the FGD.

Mechanisms for High Efficiency AQCS

The high efficiency AQCS has the following additional features.

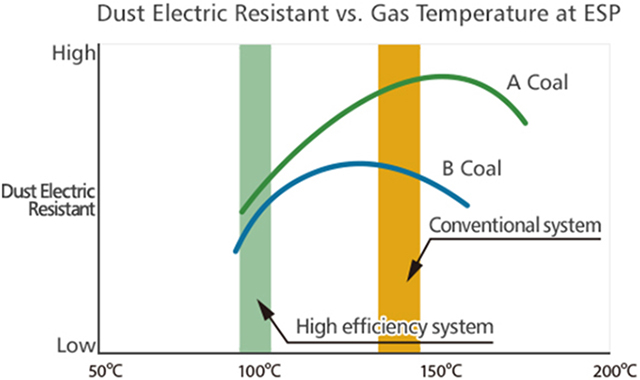

1. Improved ESP Performance and Lower Dust Emissions

- Decrease ESP Inlet Gas Temp.

- Decrease Dust Electric Resistance

- Improve ESP Performance

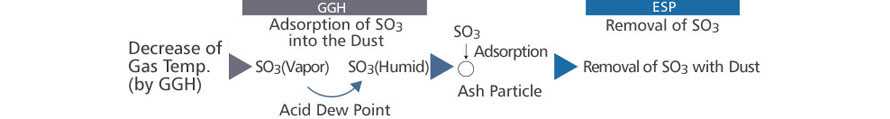

2. Higher SO3 Removal Performance

Removal of SO3 contributes to such effects as corrosion protection of equipment and prevention of the blue plume.

Features

We have developed not only NOX, SO2, SO3 and particulate control technologies but also mercury (Hg) control technologies to satisfy multiple pollutant control needs.

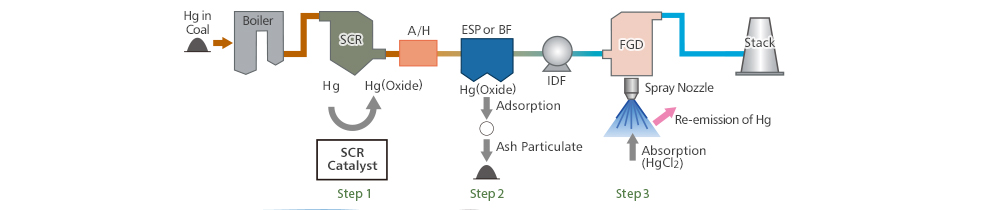

Mechanisms for Mercury Control

- Step 1

Oxidation of Mercury Using SCR Catalyst - Step 2

Adsorption & Neutralization of Mercury on Ash Particles, Captured by ESP or BF - Step 3

Absorption of Mercury (HgCl2) at the Wet FGD

Major Technologies for Mercury Control

Three core technologies for mercury control are introduced below.

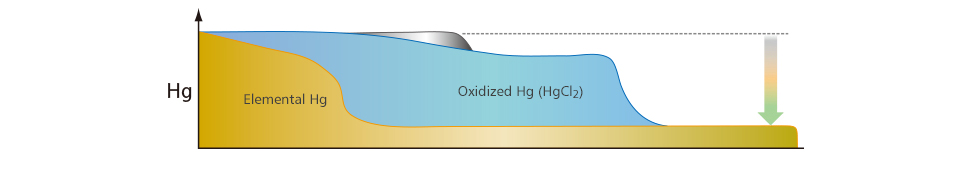

Mercury Oxidation Technology

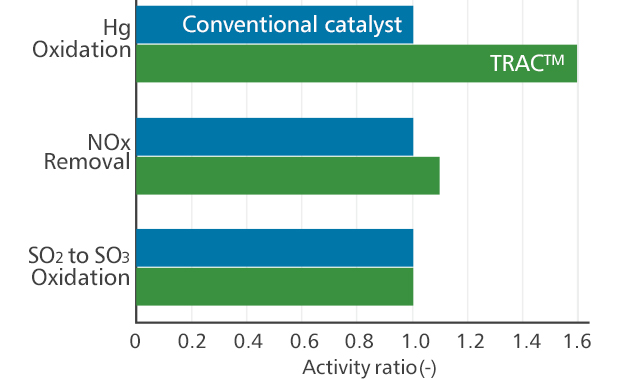

Mercury Oxidation Catalyst (TRiple Action Catalyst: TRACTM)

TRiple Action Catalyst (TRACTM) achieves higher mercury oxidation and higher NOX reduction with low SO2 to SO3 oxidation.

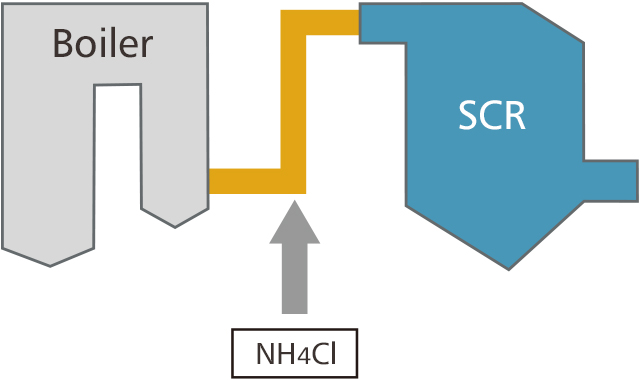

Halogen Injection

Halogen injection is technology to enhance mercury oxidation at the SCR. Mercury chloride is removed by scrubbers.

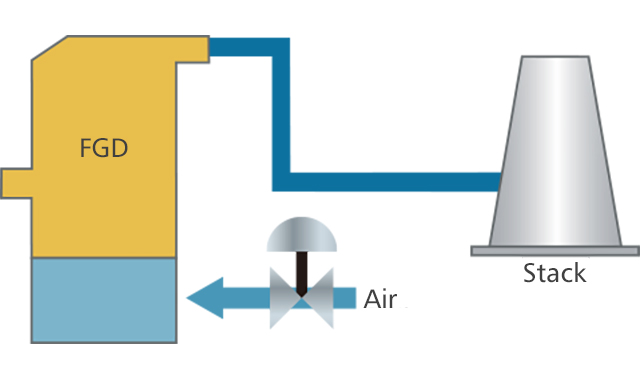

Technology to Prevent Re-emission of Mercury at Wet FGD

ORP Control

ORP (Oxidation-Reduction Potential) Control can prevent re-emission of mercury chloride in limestone / gypsum slurry at the scrubber.

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report