Steam Turbines for Thermal Power Plants (Up to 1,200 MW)

Characteristics

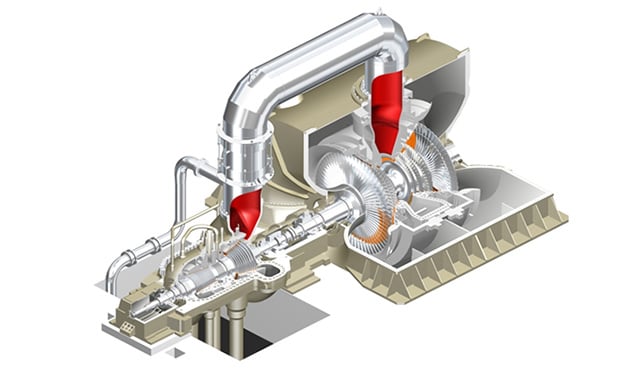

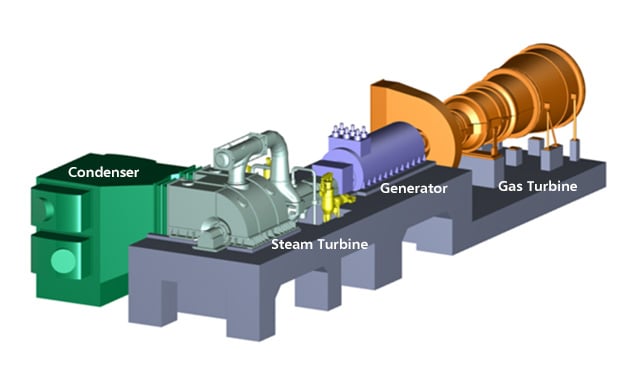

The optimal last stage blade (LSB) length and number of casings is selected based on the steam exhaust conditions. By combining the high pressure (HP) turbine and intermediate pressure (IP) turbine into a single casing, the turbine can be made more compact, thus reducing the number of components and required area for installation. On top of reducing costs related to civil construction and installation work, maintenance is also easier due to reduced number of spare parts and required inspection period. For Steam Power Plants, to increase overall plant efficiency, up to 9 extractions for feedwater heating are possible. For the low pressure (LP) turbine, exhaust direction is not limited to downward exhaust, but can also be designed for sideward exhaust.

Two Casing Turbine

(HP/IP Turbine - LP Turbine)

For GTCC Plant Applications (312 MW)

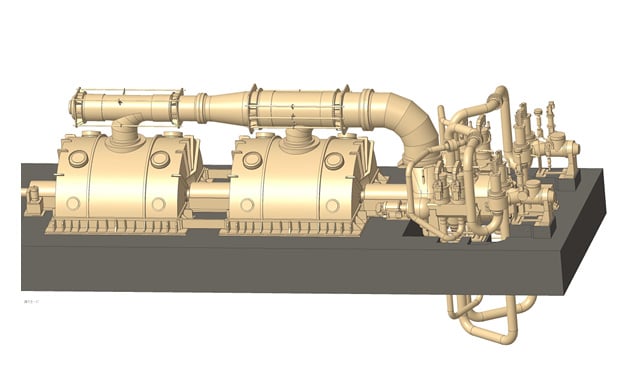

Three Casing Turbine

(HP/IP turbine - LP Turbinebatu ×2)

For Steam Power Plant Applications (670 MW)

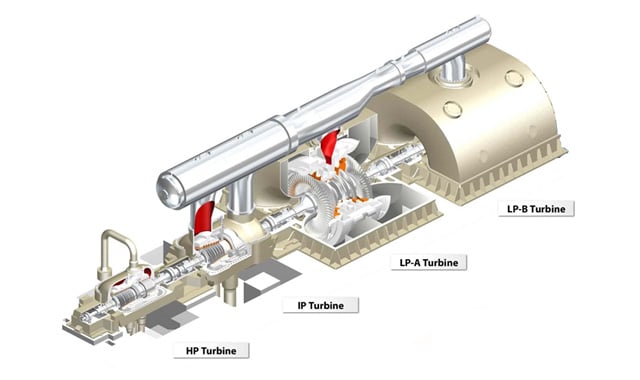

Four Casing Turbine

(HP Turbine - IP Turbine - LP Turbine ×2)

For Steam Power Plant Applications (1,000 MW)

Sideward Exhaust Turbine and Condenser

Steam Turbine Specifications

| No. of casings | Two Casings (HP/IP Turbine - LP Turbine) Three Casings (HP/IP Turbine - LP Turbine ×2) Three Casings (HP Turbine - IP Turbine - LP Turbine) Four Casings (HP Turbine - IP Turbine - LP Turbine×2) Five Casings (HP Turbine - IP Turbine - LP Turbine×3) |

|---|---|

| Output | Up to 1,200 MW |

| Main steam conditions | Up to 28.0 MPa / Up to 600°C |

| Reheat steam conditions | Up to 630°C |

| Revolutions per minute | 3,000 min-1 (50 Hz) / 3,600 min-1 (60 Hz) |

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report