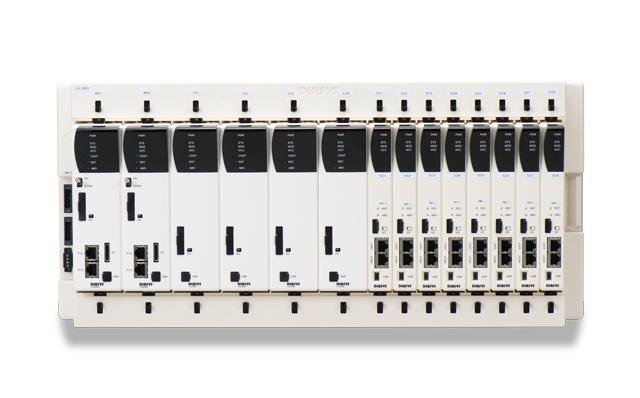

Dependable Process Station (DPS)

Overview

This control equipment is used for automated plant control, various operational processing and plant ON/OFF control.

I/O signals with the plant field are processed through IO modules and control logic is computed through a CPU module to control the plant.

Functions of the Dependable Process Station (DPS)

High-reliability Controller with High Speed and Capacity

The DPS is able to perform calculations as fast as every 5 millisecond, making it suitable for application in systems that require high-speed control.

In addition, as the high capacity means that control operations can be executed with fewer controllers than the MPS, systems can be configured at a lower cost.

| MPS | DPS | |

|---|---|---|

| Number of Modules | 1 - 500 modules/controllers | 1 - 9,216 modules/controllers |

| Number of IO Points | 8 - 4,000 point modules/controllers | 8 - 73,728 point modules/controllers |

| Minimum Computation Period | 10 ms | 5 ms |

| Number of Logic Sheets (Maximum) | Regular Sheets: 1,023 or 4,095 | Regular Sheets: 4,095 |

Flexible Hardware Configurations

To maintain safety while raising the utilization rate, redundancy mechanisms that ensure continued operation even when a specific area fails are required.

DPS Logic Solver supports single to four-level redundancy, and all other cards and modules support redundancy.

By freely combining configurations and only implementing redundancies where needed, customers can maximize plant utilization rates at the optimum cost.

| Module Name | Redundancy |

|---|---|

| CPU Module Logic Solver | 1~4 |

| Higher Order General Communication Module Network Adapter (NA) | 1~2 |

| Lower Order General Communication Module IOScanner (IOS) | 1 - 2 × 4 groups

|

| IO Module | 1~2 |

Card Module Lineup

Check the following pages for information about our lineup of DPS modules.

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report