Multiple Process Station (MPS)

Overview

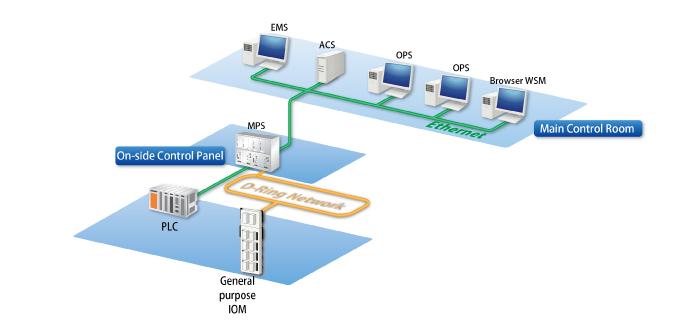

A DIASYS Netmation Multiple Process Station (MPS) is a controller used for control operation and ON/OFF control for the site.

An attention to detail is employed throughout the MPS to ensure reliability and controllability.

Functions of the Multiple Process Station (MPS)

Ensuring High Reliability from System to Hardware

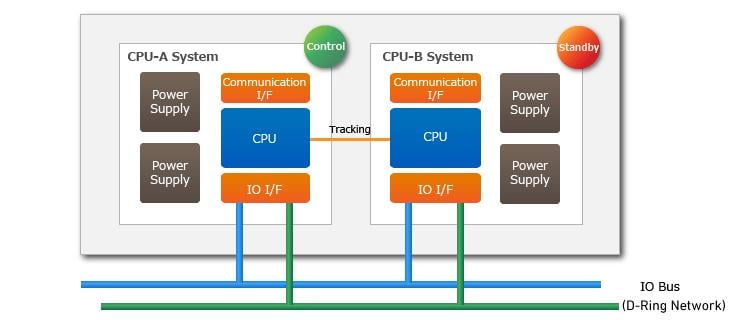

An MPS ensures system reliability by implementing redundancies in CPU processing modules, the power supply and network. It also incorporates a self-diagnostic function that detects hardware and software failures.

The CPU module has hot-swap redundancy. One CPU is used for control and the other is on standby. The calculation results from the control CPU are used to perform the relevant control tasks. The standby CPU receives data from the control CPU periodically (tracking), and continually retains the same calculation results as the control CPU in preparation for failover.

Flexible System Configuration to Meet Users' Requests

A full lineup of hardware supports configurations that meet a wide range of uses. The system can also be connected to a programmable logic controller (PLC) and various fieldbus devices, enabling integrated control while maintaining existing facilities, and helping to reduce costs.

Maintenance while Placing a Priority on Continuous Facility Operation

Should an I/O module fail, it can be replaced without having to shut down the facility. In addition, when you want to make changes to control logic, graphics or parameter values, you can change them without affecting other settings or stopping the currently running MPS.

Facilities can be operated in a manner that is tailored to customer needs.

Card Module Lineup

Check the following pages for information about our lineup of MPS card modules.

- MPS Components

- D-Ring Network - General IO Module

- ControlNet™ - FLEX I/O Module(Note)

(Note)The ControlNet-FLEX I/O module was discontinued in 2020 as a dedicated device for DIASYS Netmation (C-Net).

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- Fuel Cells

- Additive Manufacturing

- Catalogue

- HIACS Series

- Technical Report