Geothermal Power Plant A

Overview

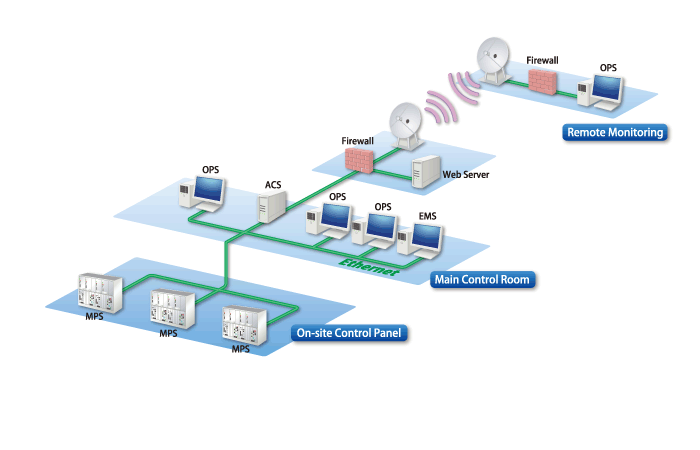

A geothermal power plant extracts a portion of geothermal energy in the form of steam to drive turbines. In many cases, these plants are constructed at high altitudes near volcanoes, or in hilly areas. DIASYS caters to customer needs for remote operation and monitoring of the plant through communications between operator stations installed in distant customer offices and control equipment installed at the power plant.

Background to Introduction and Challenges Faced

To build a system for remote monitoring and operation, Mitsubishi Power needed to prepare a communications infrastructure to handle the large communication volume generated by a conventional control system. With DIASYS, Mitsubishi Power was able to utilize the existing low-volume communications infrastructure to achieve remote monitoring and operation by applying MHI Card Communication, an in-house communication protocol that features a minimal communication load.

Effects of Introduction

For Geothermal Power Plant A, an operator station was installed in a customer monitoring center around 100 km away from the plant and the customer's microwave link for security was used to achieve remote monitoring and operation.

System Configuration

Configurations and Specifications

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- FXtoLS Adapter

- DIASYS Solutions

- Fuel Cells

- Others

- Catalogue

- HIACS Series

- Technical Report